Cross-laminated timber transshipping transportation device

A cross-lamination and transfer technology, applied in storage devices, transportation and packaging, conveyors, etc., can solve problems such as the inability to further shorten the solidification time limit, the inability to realize automated production, and the idleness of personnel and connecting equipment, so as to improve the overall performance. Work efficiency, save man-hours, and ensure the effect of safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

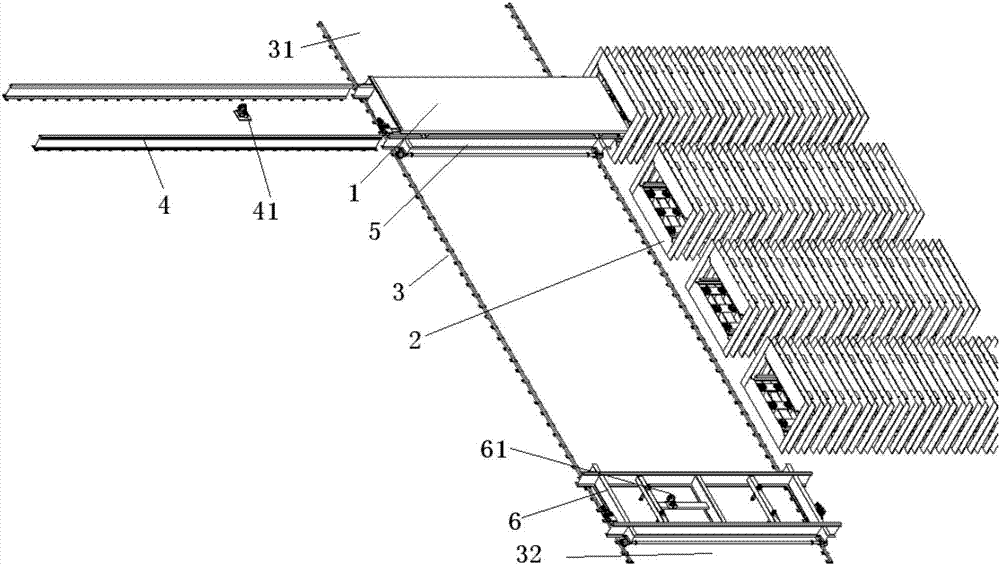

[0028] Such as figure 1 As shown, the interlaced laminated wood transport device of the present invention includes a plurality of support vehicles 1, a plurality of presses 2, and a connecting vehicle that only moves along the transverse rail 3.

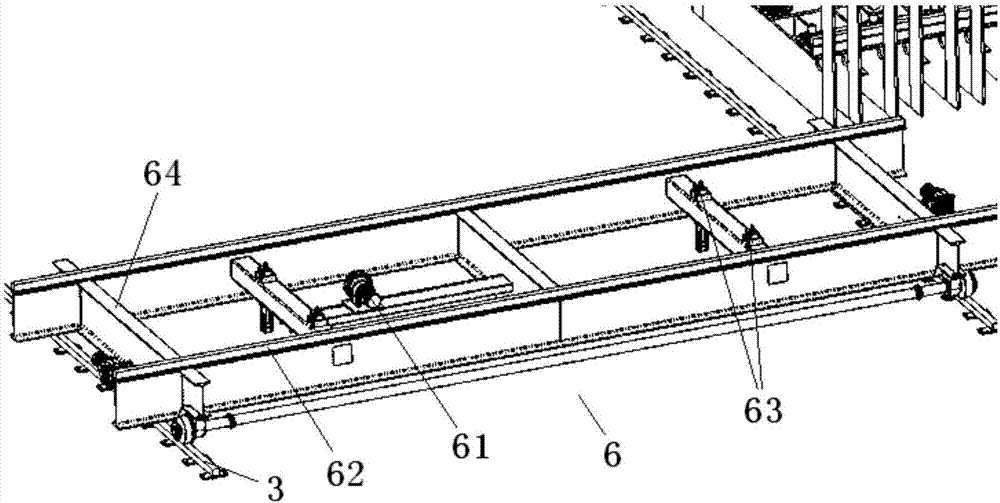

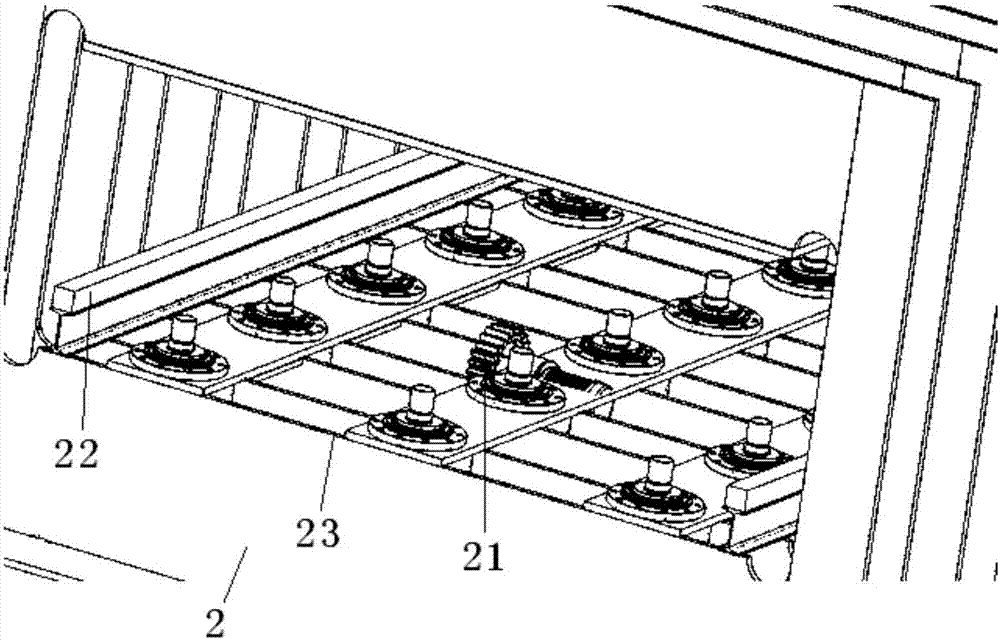

[0029] One side of the transverse track 3 is vertically provided with a longitudinal track 4, and a plurality of presses 2 are arranged on the other side of the transverse track, and the feed port of each press 2 faces the transverse track 3; the shuttle car moves along the transverse track to the longitudinal track 4 side, it can be connected with the longitudinal track 4, so that the supporting car moves from the longitudinal track 4 to the connecting car or drives out from the connecting car to move along the longitudinal track 4; the connecting car moves along the transverse track 3 to the pressing When the feed port of the press is connected, it can be connected with the press track in the press 2, so that the supporting car 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com