Common-path forward-reverse simultaneous measuring device for fiber optic gyroscope ring

A fiber optic gyroscope and measuring device technology, which is applied in measuring devices, gyroscopes/steering sensing equipment, Sagnac effect gyroscopes, etc., can solve the problem that the controllable reversing mechanism does not achieve simultaneity and cannot strictly control the consistency of the system , There is no way to achieve distributed measurement and other problems, to reduce measurement inconsistency, eliminate the impact of environmental factors, and reduce test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

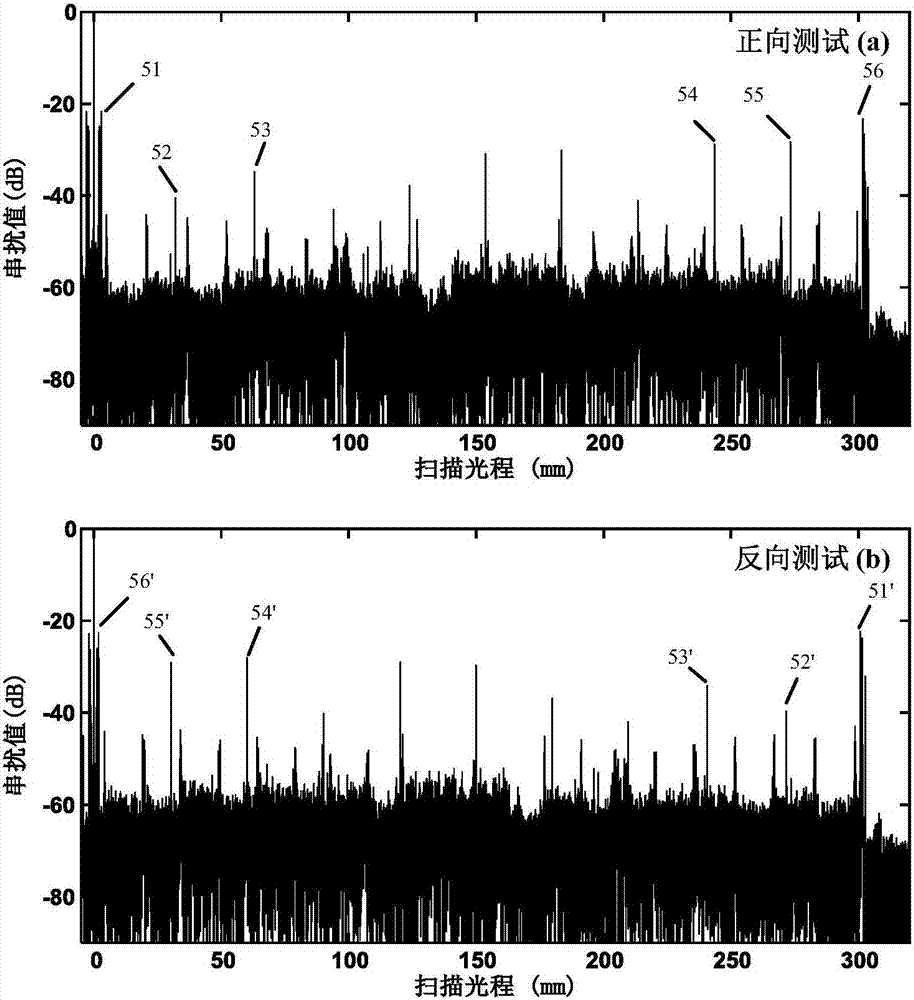

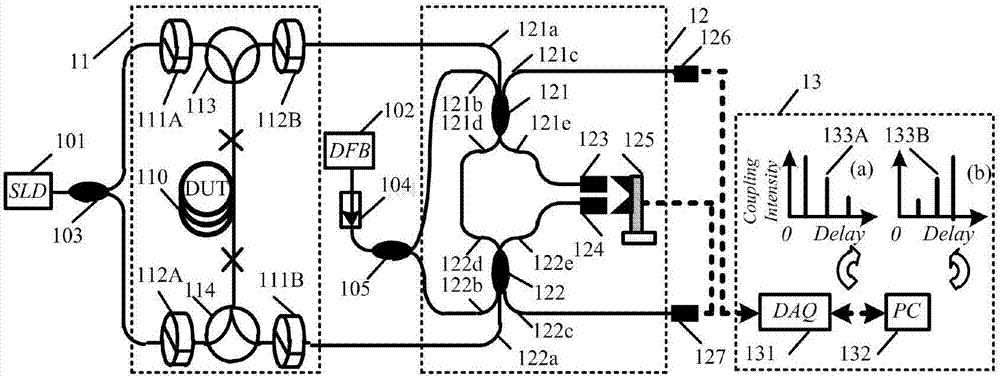

Embodiment 1

[0042] The measuring device is attached figure 1 As shown, the device parameters are selected as follows:

[0043] (1) The broadband light source 101 is an SLD light source with a central wavelength of 1550nm, a half-spectrum width greater than 45nm, a fiber output power greater than 5mW, and an extinction ratio greater than 6dB;

[0044] (2) The optical fiber device 110 to be tested is a panda-type polarization-maintaining optical fiber with a length of 500 m;

[0045] (3) The working wavelength of the first polarizer 111A and the first polarizer 111B, the second polarizer 112A and the second analyzer 112B is 1550nm, the extinction ratio is greater than 20dB, and the insertion loss is less than 3dB;

[0046] (4) The first circulator 113 and the second circulator 114 are three-port polarization maintaining circulators, the return loss of which is greater than 55dB, and the insertion loss is less than 1dB;

[0047] (5) Six-port couplers 121, 122, and other optical fiber coupl...

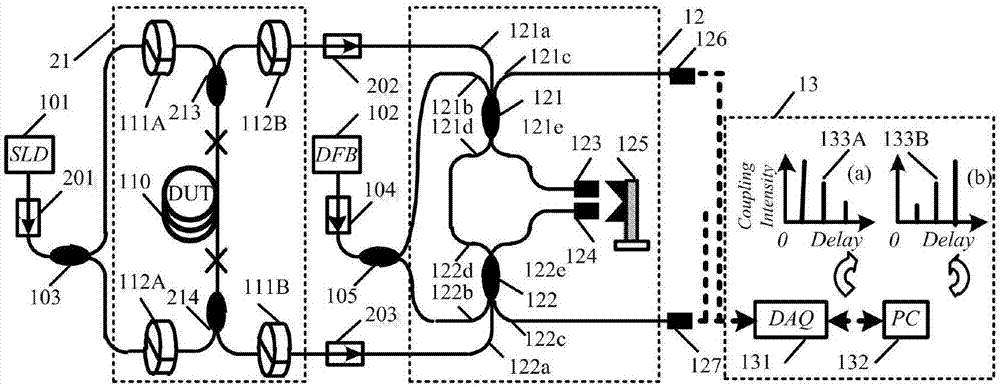

Embodiment 2

[0052] The measuring device is attached figure 2 shown, in addition to the test set 21 with the attached figure 1 Except that the test device 11 is different, the rest of the two devices are basically the same.

[0053] (1) The test device 21 includes a device under test 110, a forward coupler 213 and a reverse coupler 214 connected to both ends of the device under test 110, a first polarizer 111A and a first polarizer 111B, a first 2 polarizers 112A and a second analyzer 112B;

[0054] (2) The first coupler 213 and the second coupler 214 have the same physical parameters, and the two ends of the device under test 110 are respectively connected to one end of the forward coupler 213 and the reverse coupler 214; the first polarizer 111A and the second polarizer 112A respectively have the same physical parameters such as the polarizing angle, and the two are respectively connected to an input port of the first coupler 213 and the second coupler 214; the first polarizer 111B an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Extinction ratio | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com