Variable stiffness filler baggage device and gripper prepared by same

A filling and variable stiffness technology, which is applied in the field of variable stiffness filling bags and grippers, can solve the problems of high power consumption and scratches on items, and achieve the effects of high applicability, reduced damage, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

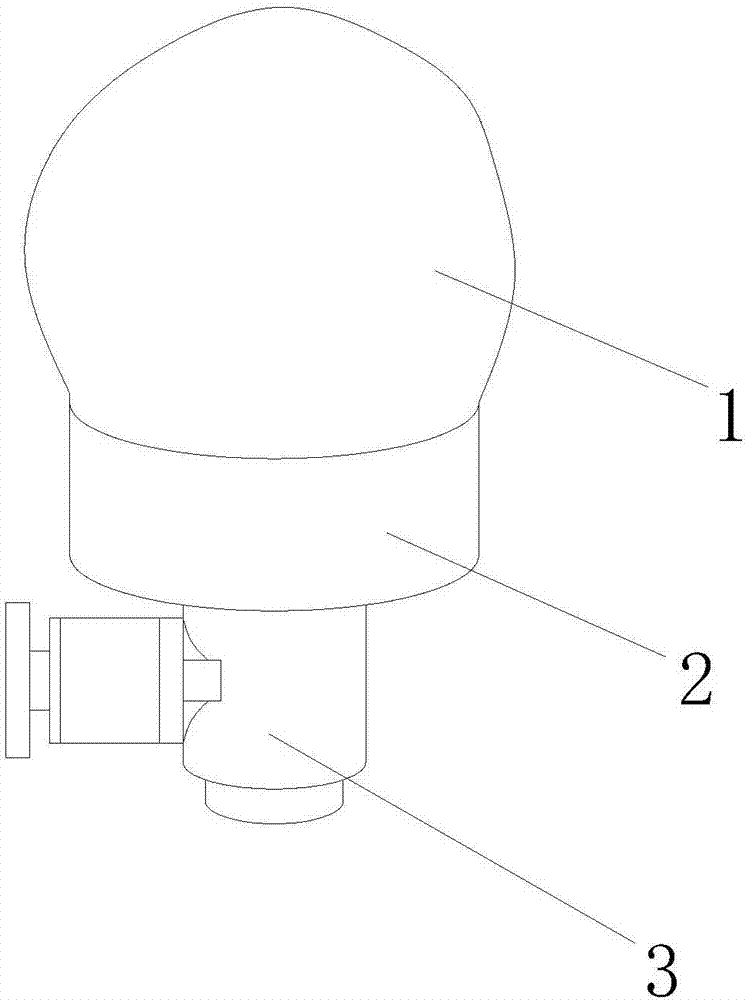

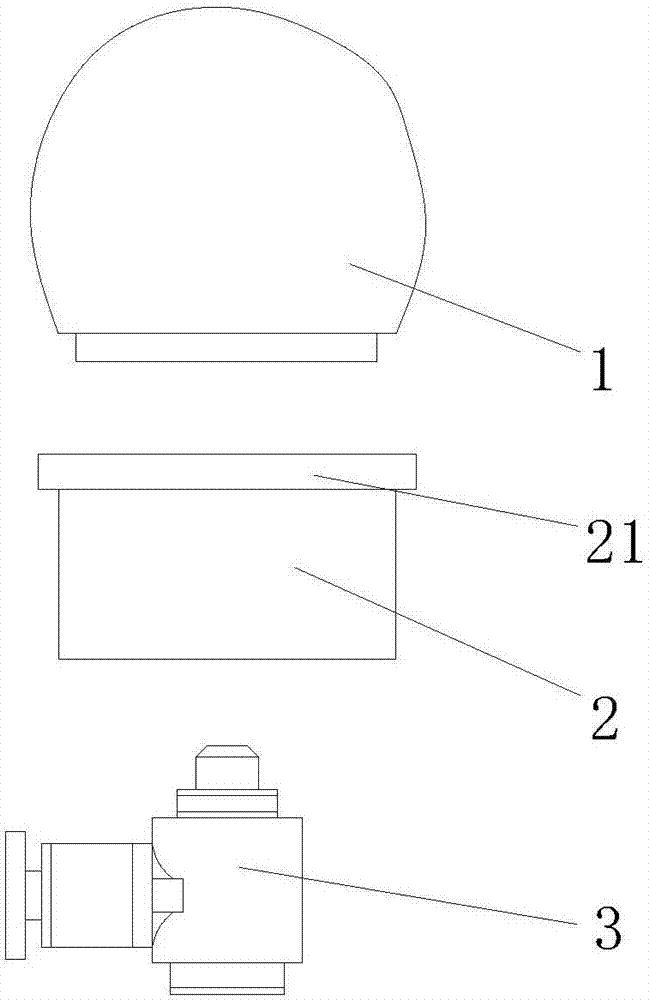

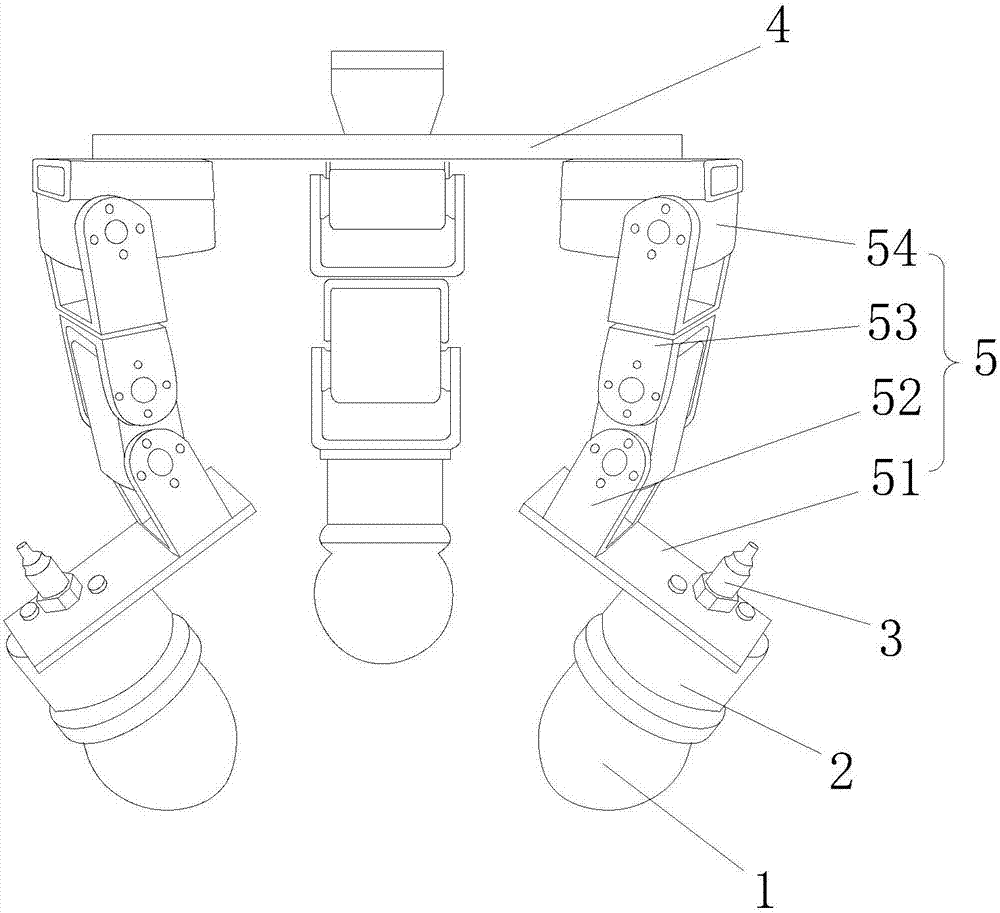

[0019] combine figure 1 and figure 2 As shown, a packing bag with variable stiffness includes an air bag 1, a base body 2 and an air core 3, the base body 2 is cylindrical, the air bag 1 is set on the top of the base body 2, the air bag 1 is filled with particles, and the air core 3 is connected to the base body At the bottom of the 2, the air core 3 is connected to an external air pump through a pipeline, which can be used to inflate and deflate the air bag 1 under the control of the control device.

[0020] Before use, put the airbag 1 on the top of the base 2, fix it with a rubber band, use its own elasticity to ensure airtightness, and then put several hexagonal nuts on the air core 3, the hexagonal nuts and the base 2 form an interference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com