Patents

Literature

58results about How to "Flexible and fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Analyzing events

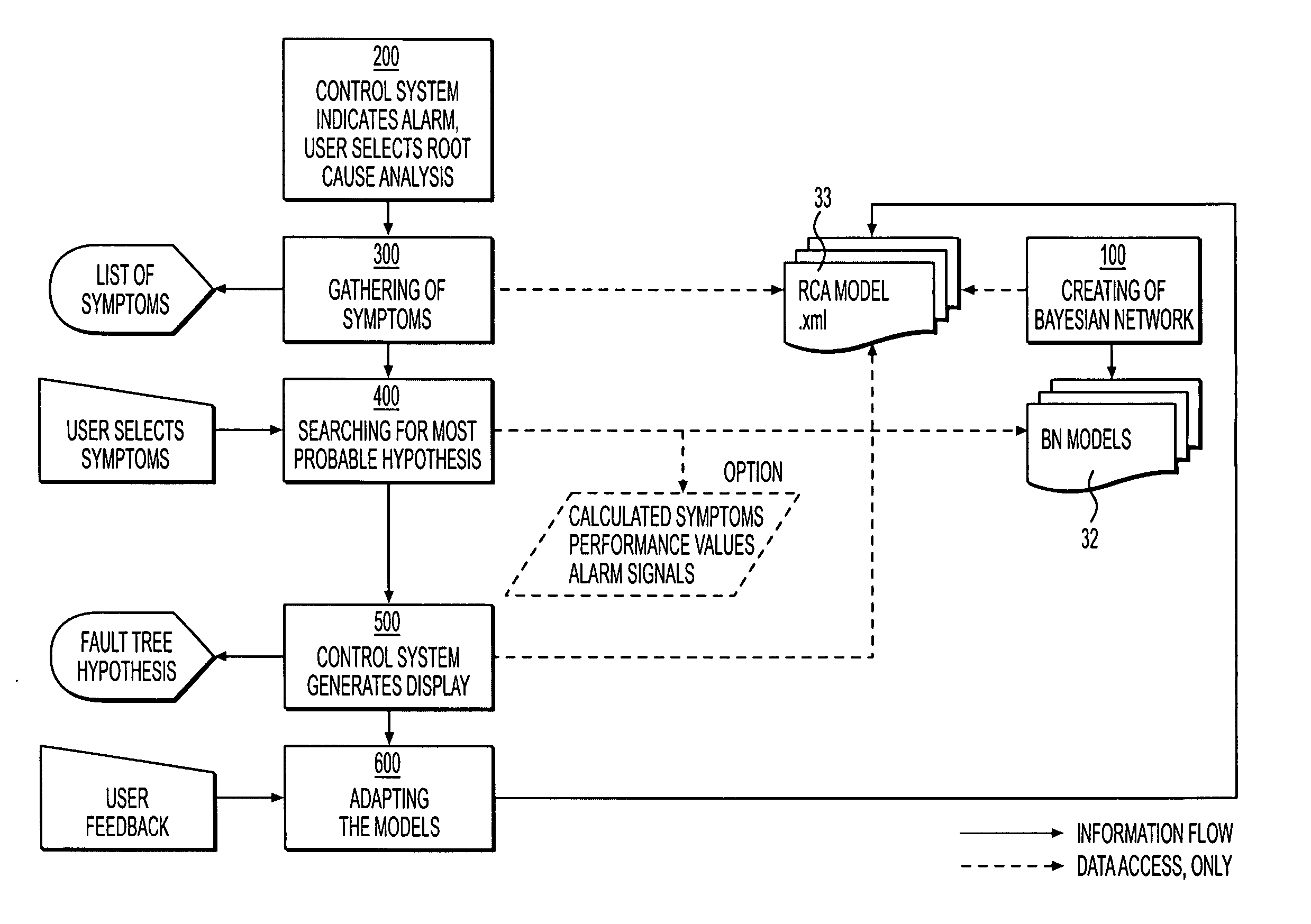

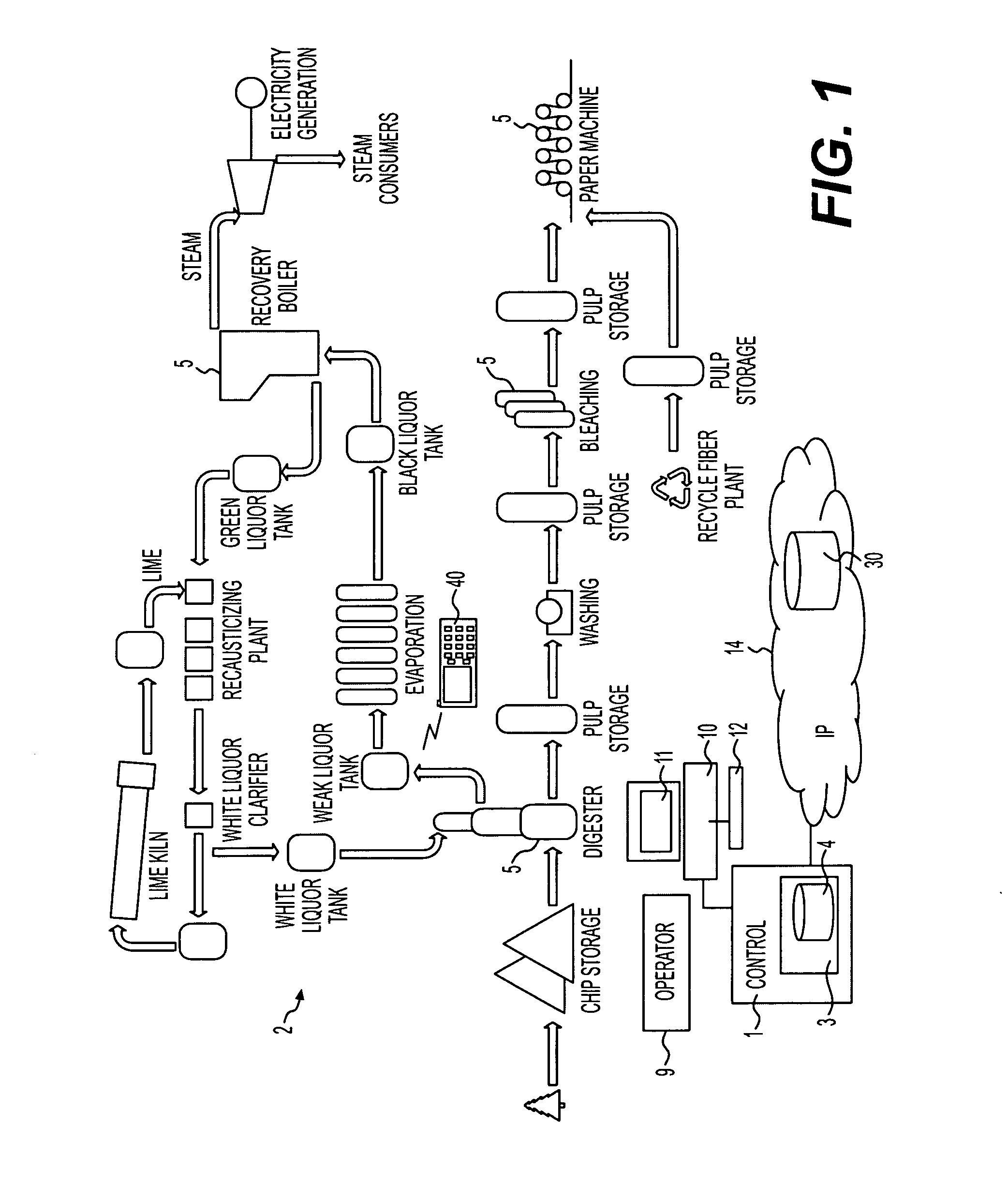

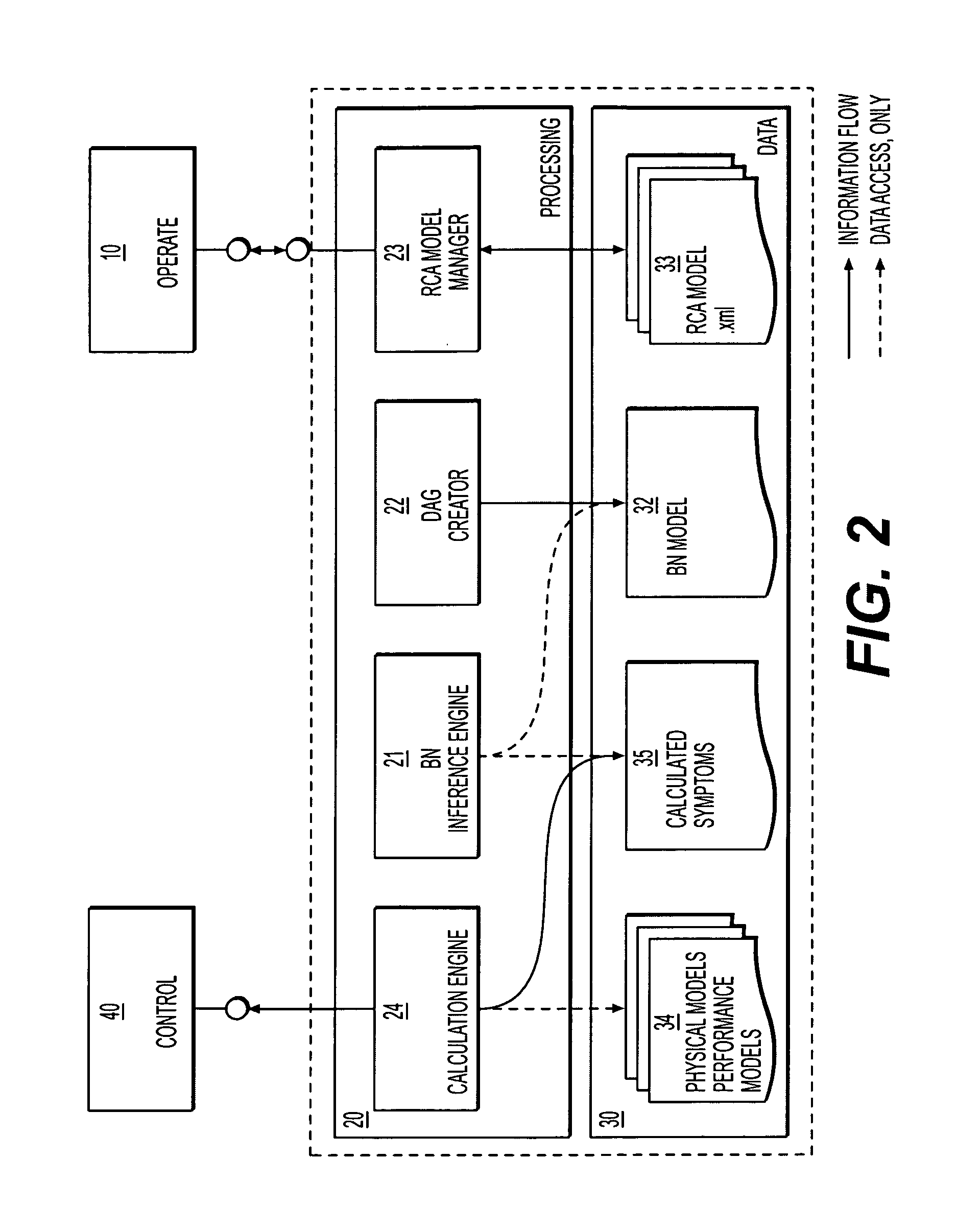

InactiveUS20050015217A1Flexible and fastFast and flexible guidanceSimulator controlElectric testing/monitoringHypothesisRoot cause

An analyzer arrangement for provision of information about a facility by means of root cause analysis. Storage assembly stores a data model that associates with the facility. The data model contains information about possible events, hypotheses for the root causes of the possible events and symptoms for the hypotheses. A processor provides root cause analysis based on the data model. An input inputs additional information for use in root cause analysis. An adaptor modifies the data model based on the additional information.

Owner:ABB (SCHWEIZ) AG

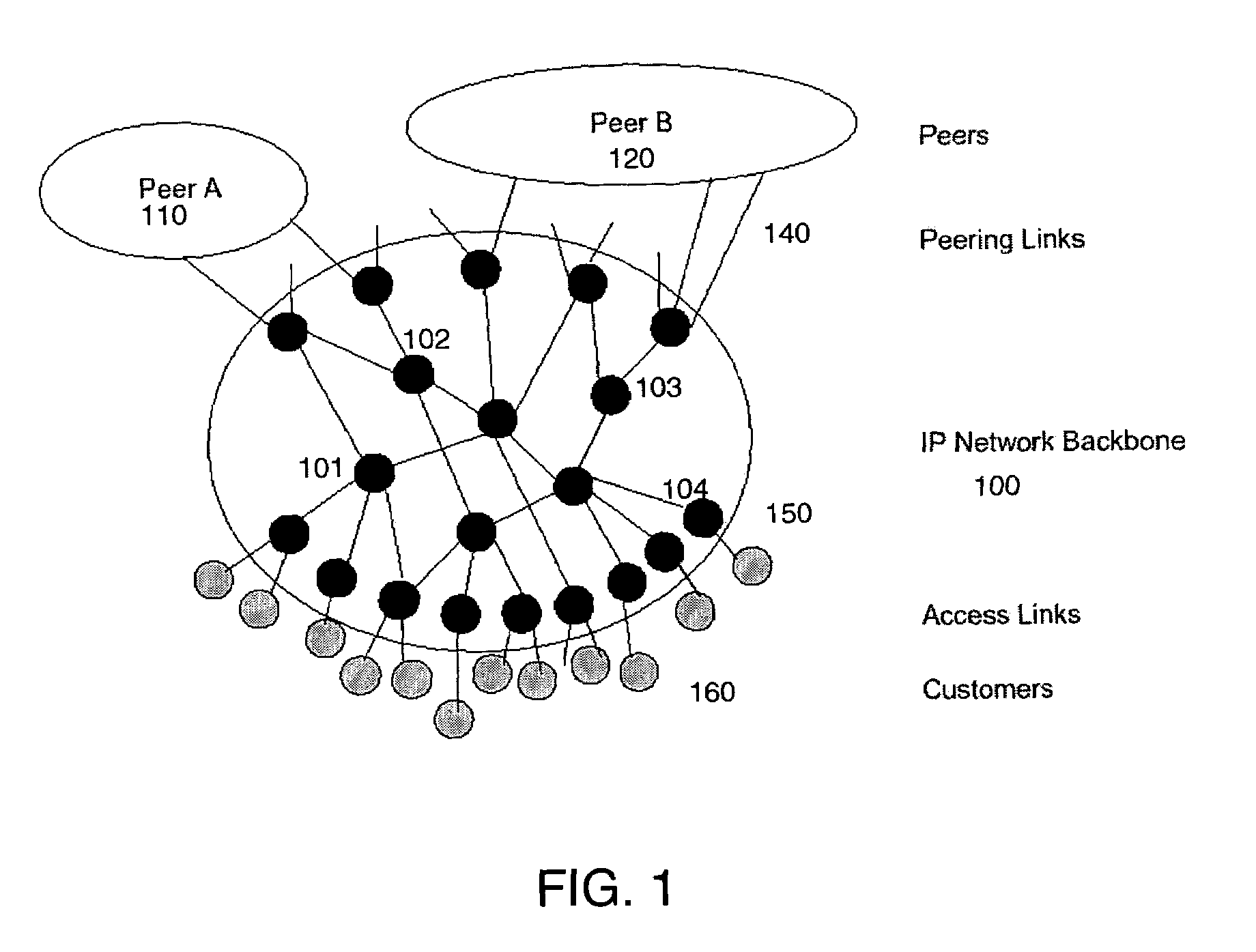

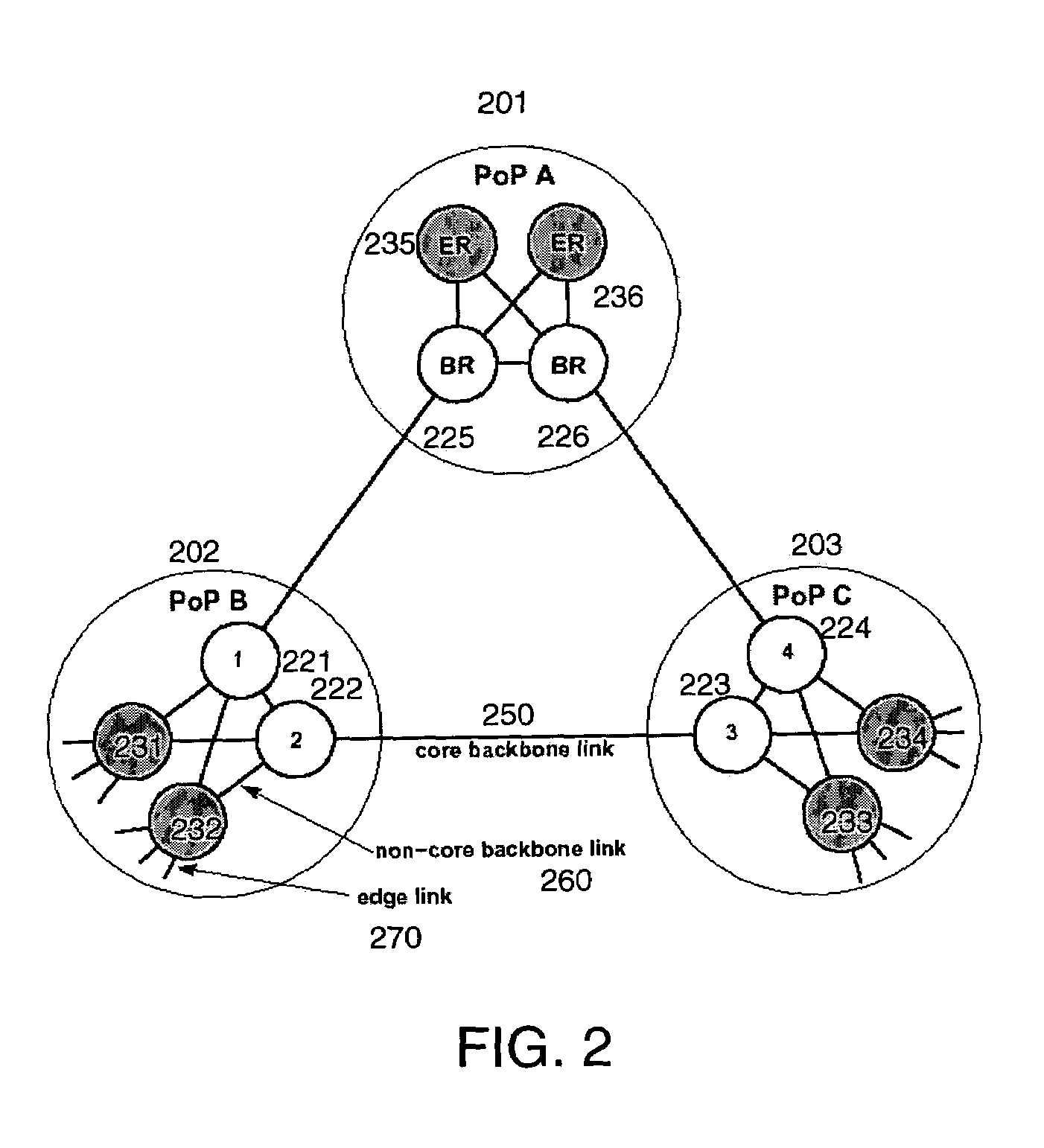

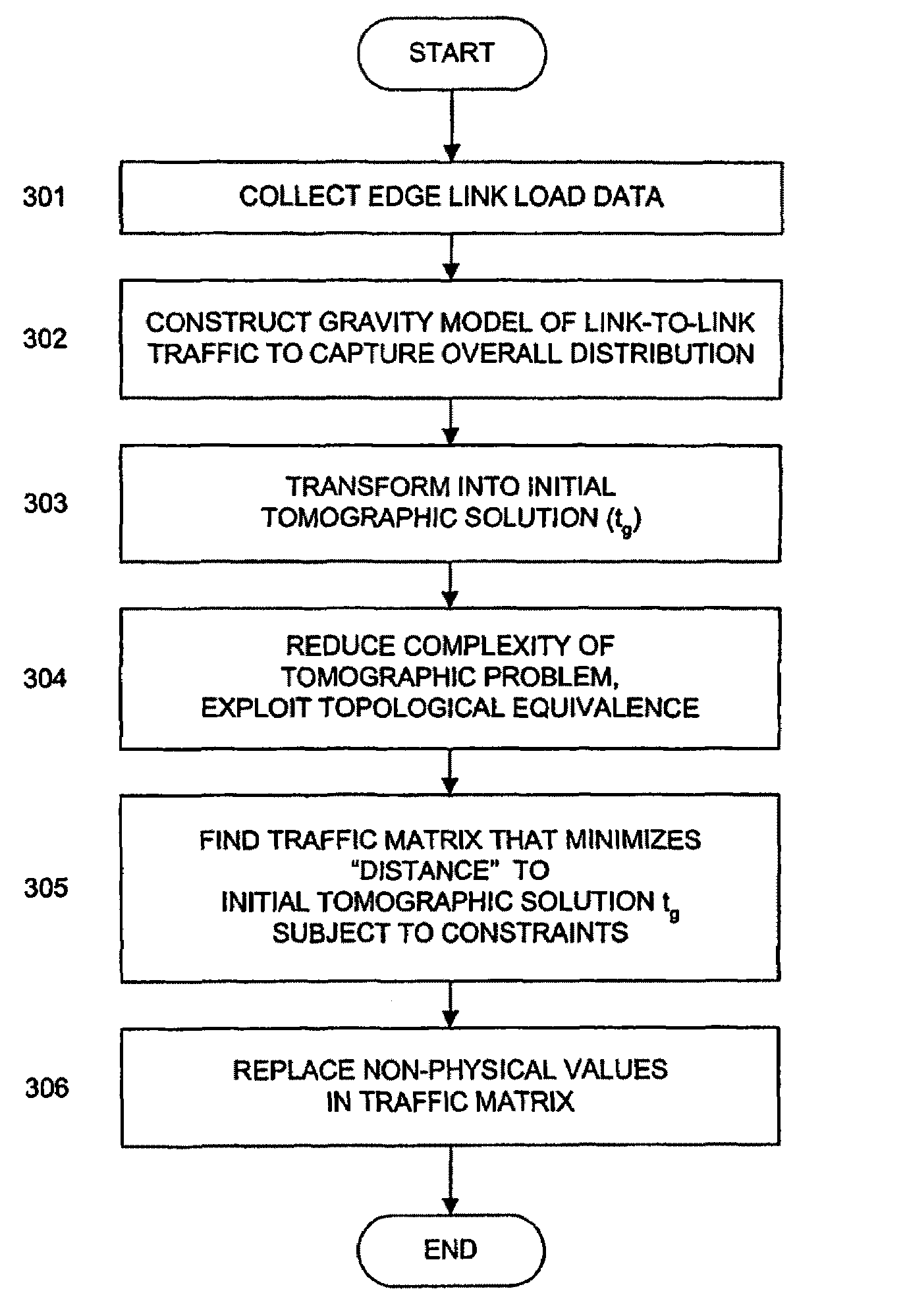

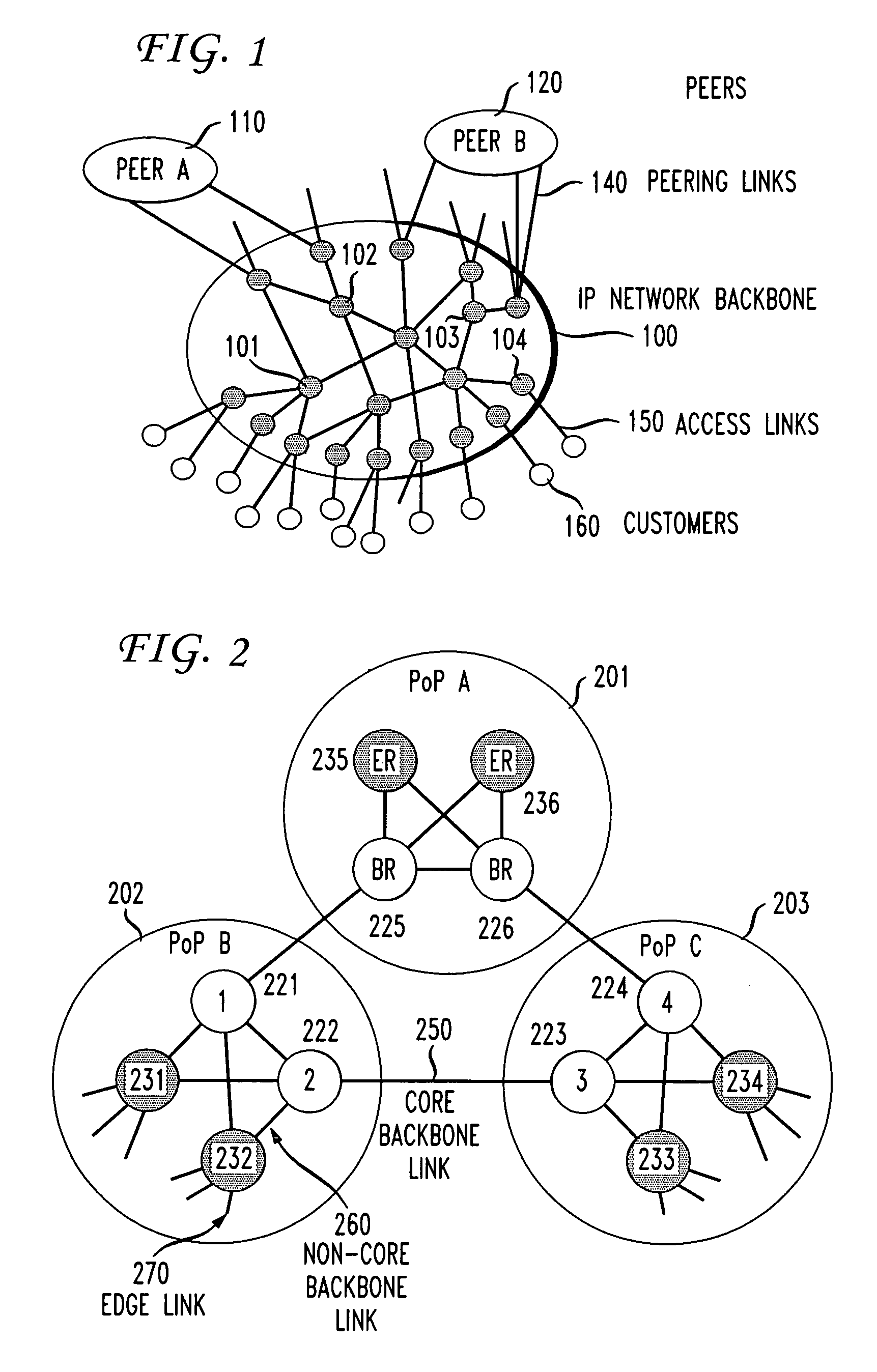

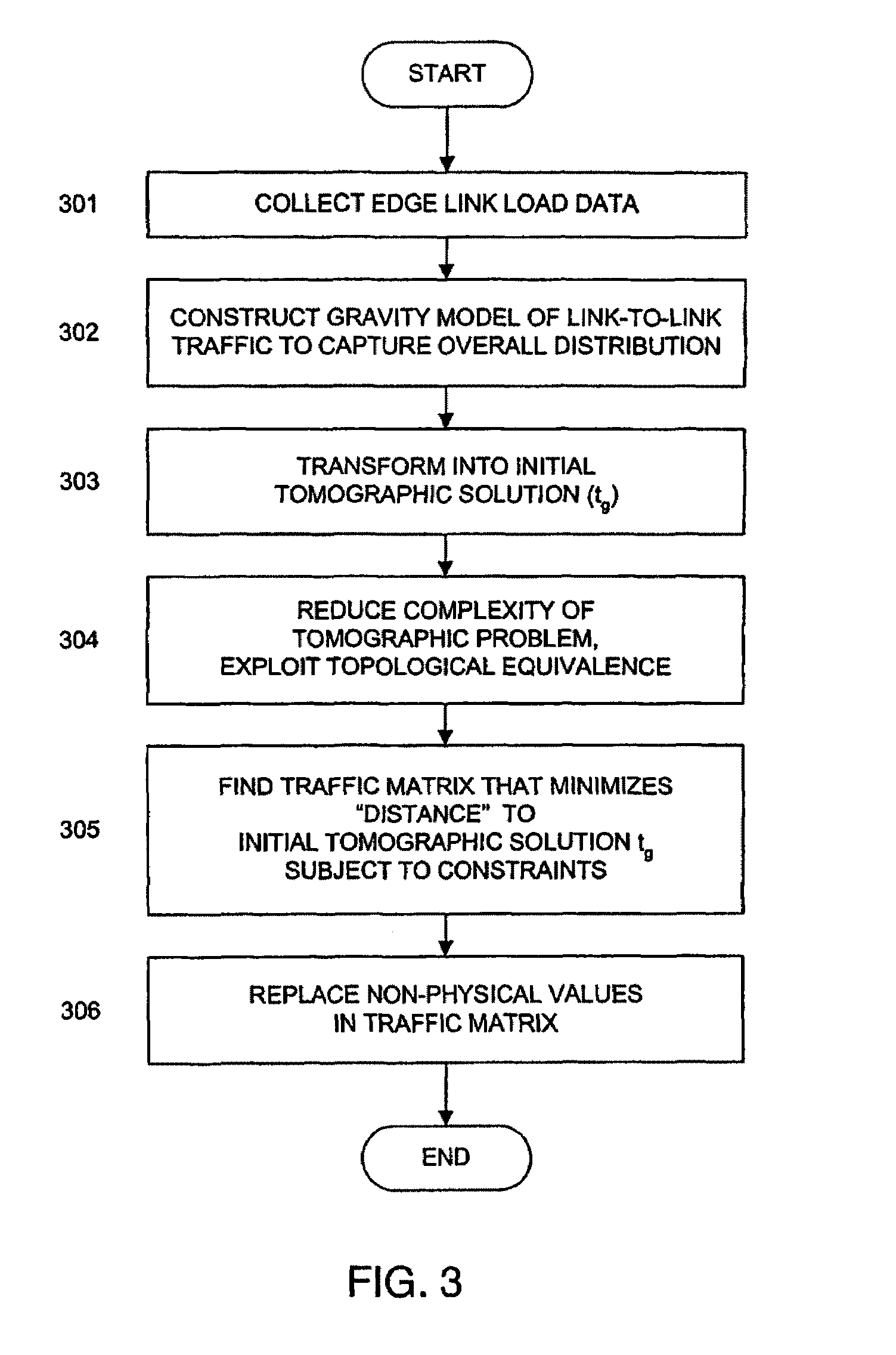

Traffic matrix estimation method and apparatus

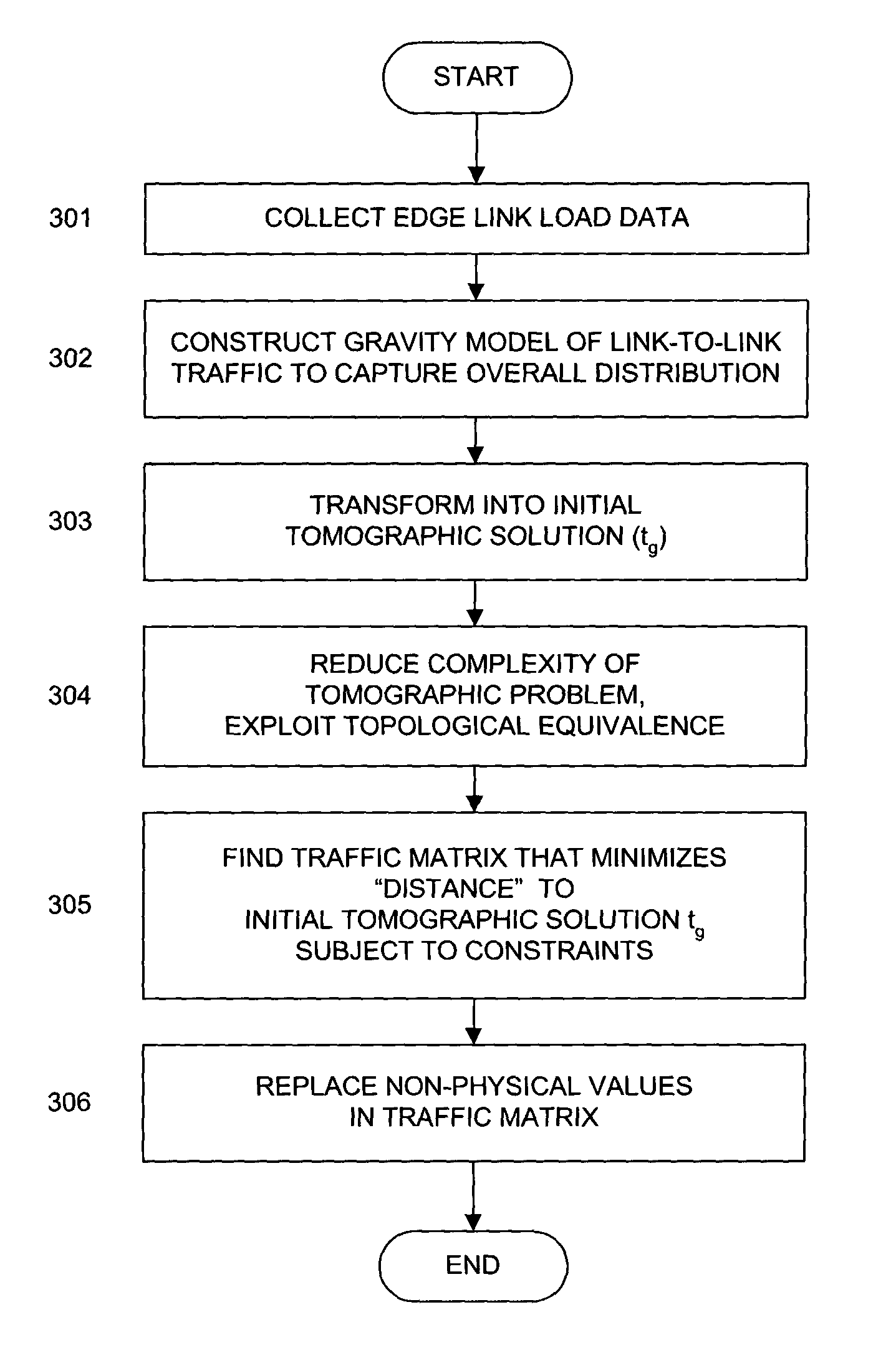

InactiveUS7293086B1Reduce dimensionalityPromote resultsDigital computer detailsData switching networksTraffic capacityDistributed computing

A method and apparatus for the estimation of traffic matrices in a network are disclosed. Mechanisms are disclosed for measuring traffic volume from a plurality of ingress points to a plurality of egress points in a large scanl network, such as an IP backbone network. The traffic matrix is advantageously inferred from widely available link load measurements such as SNMP data.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

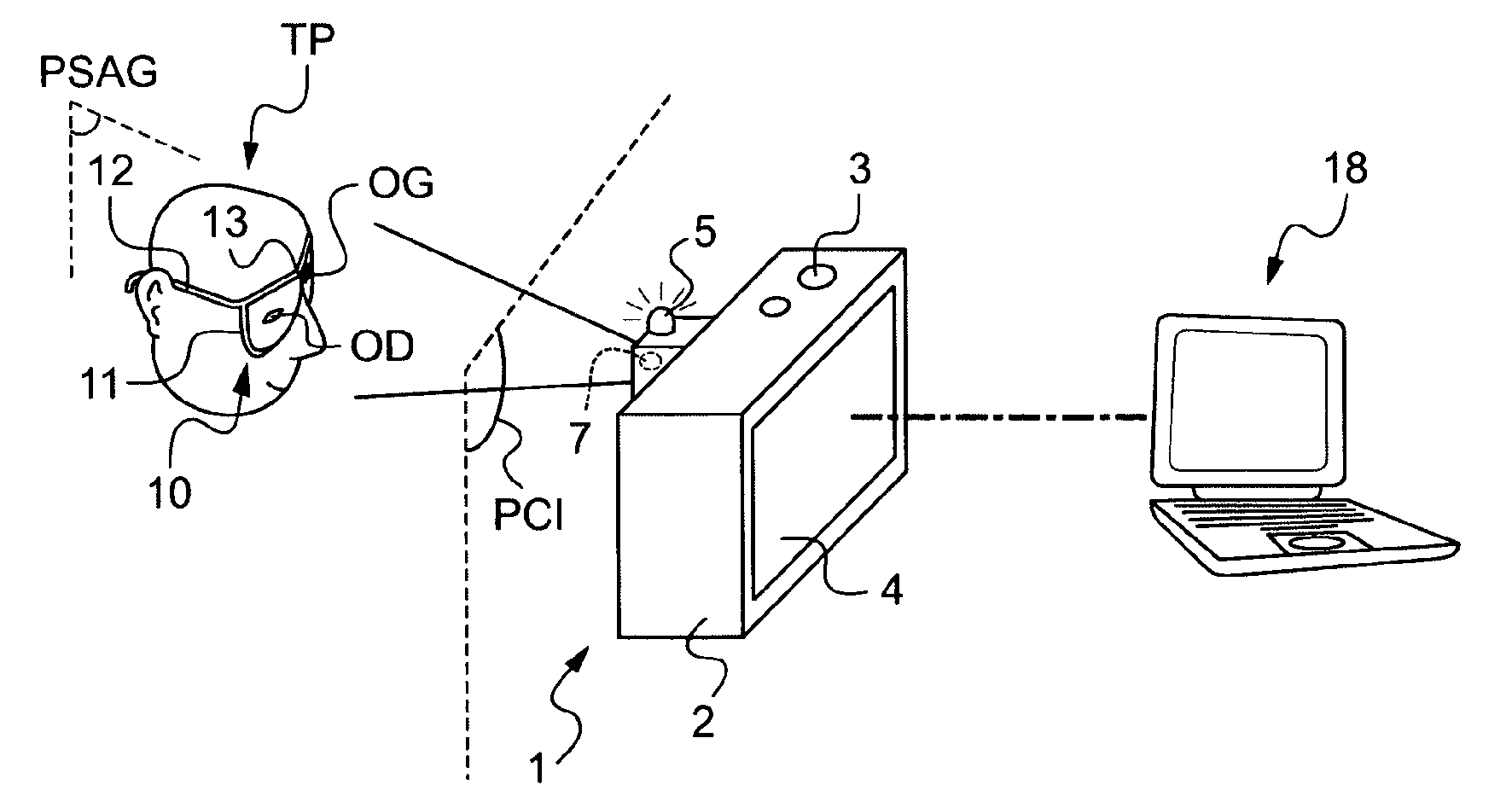

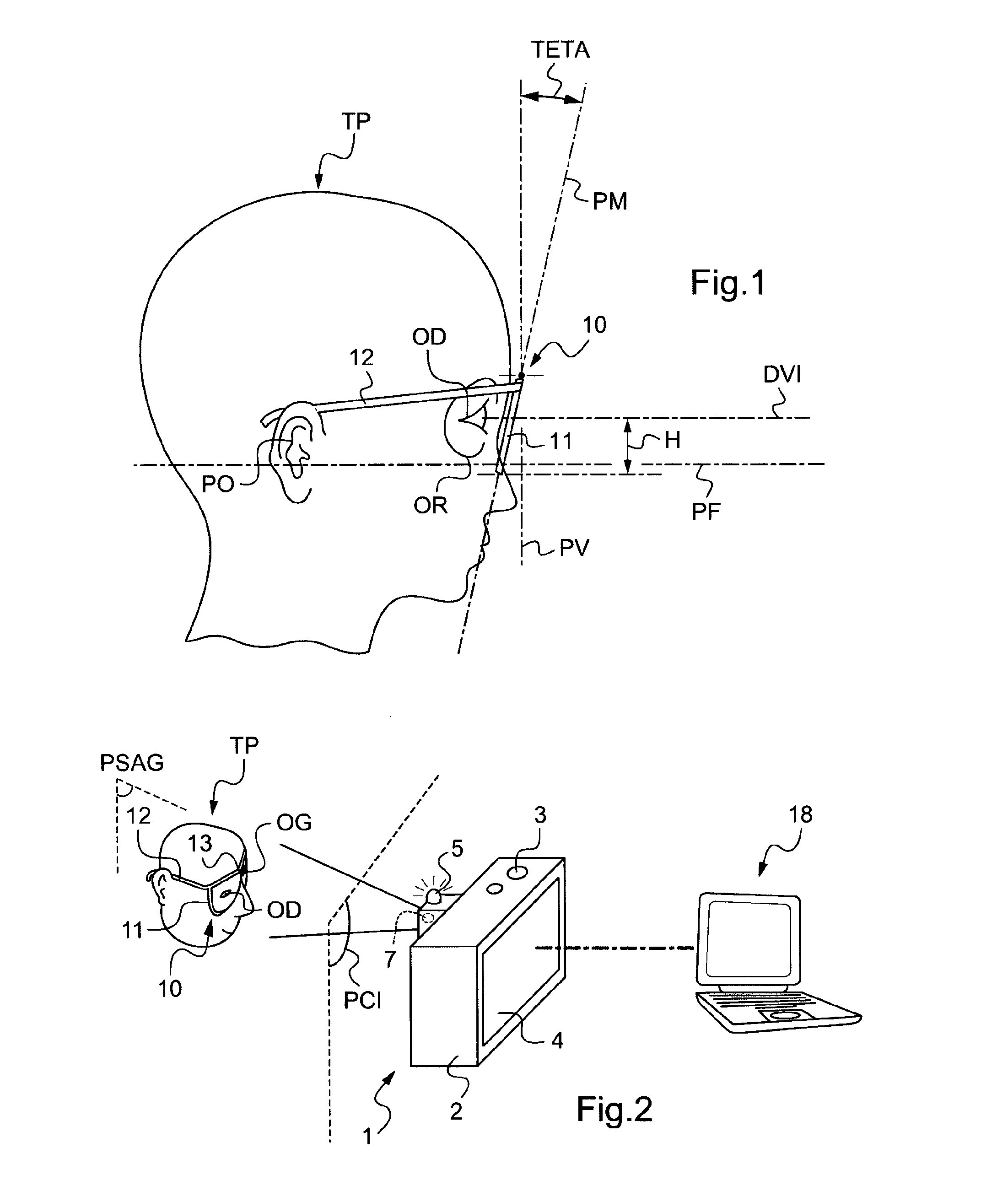

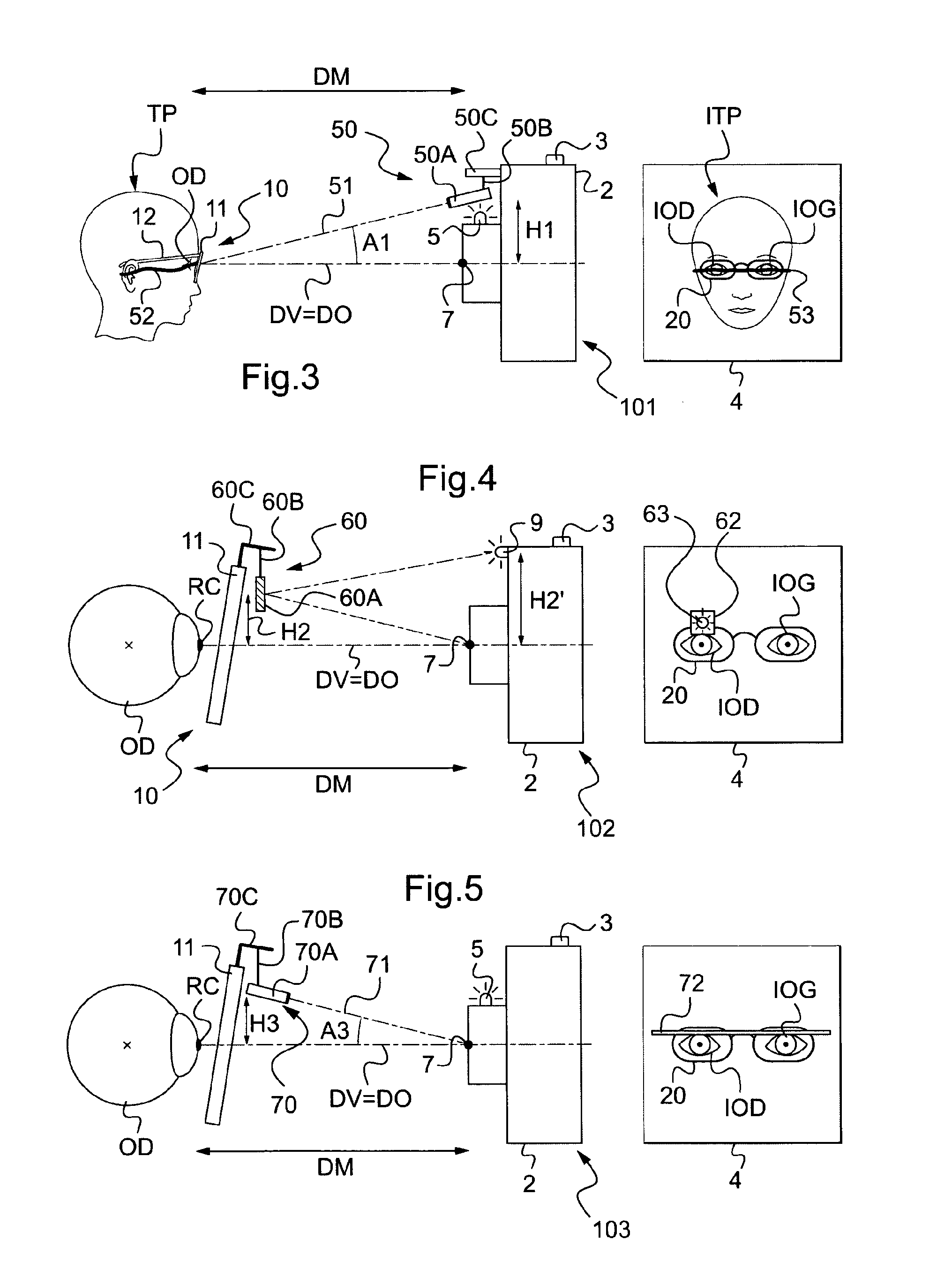

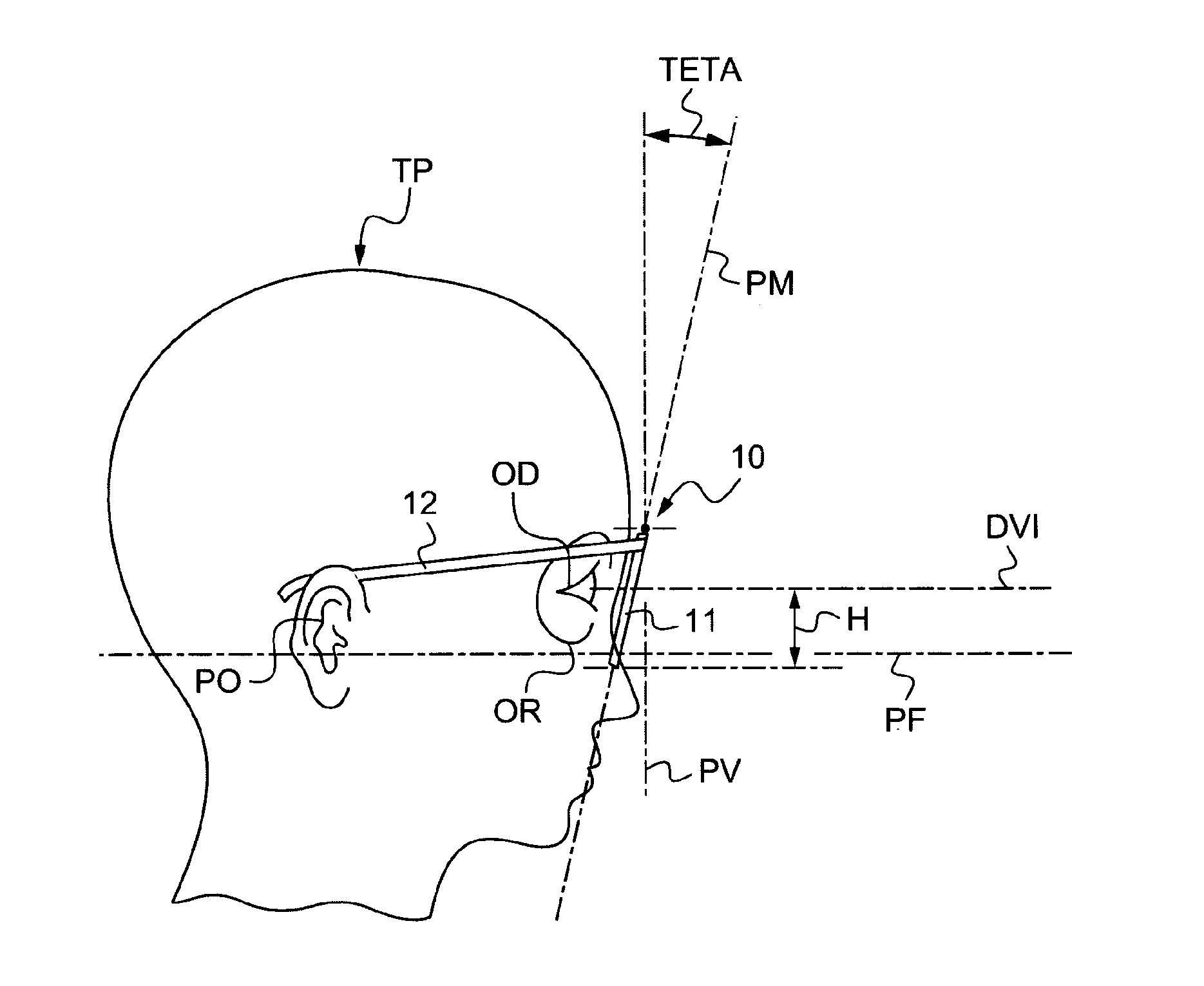

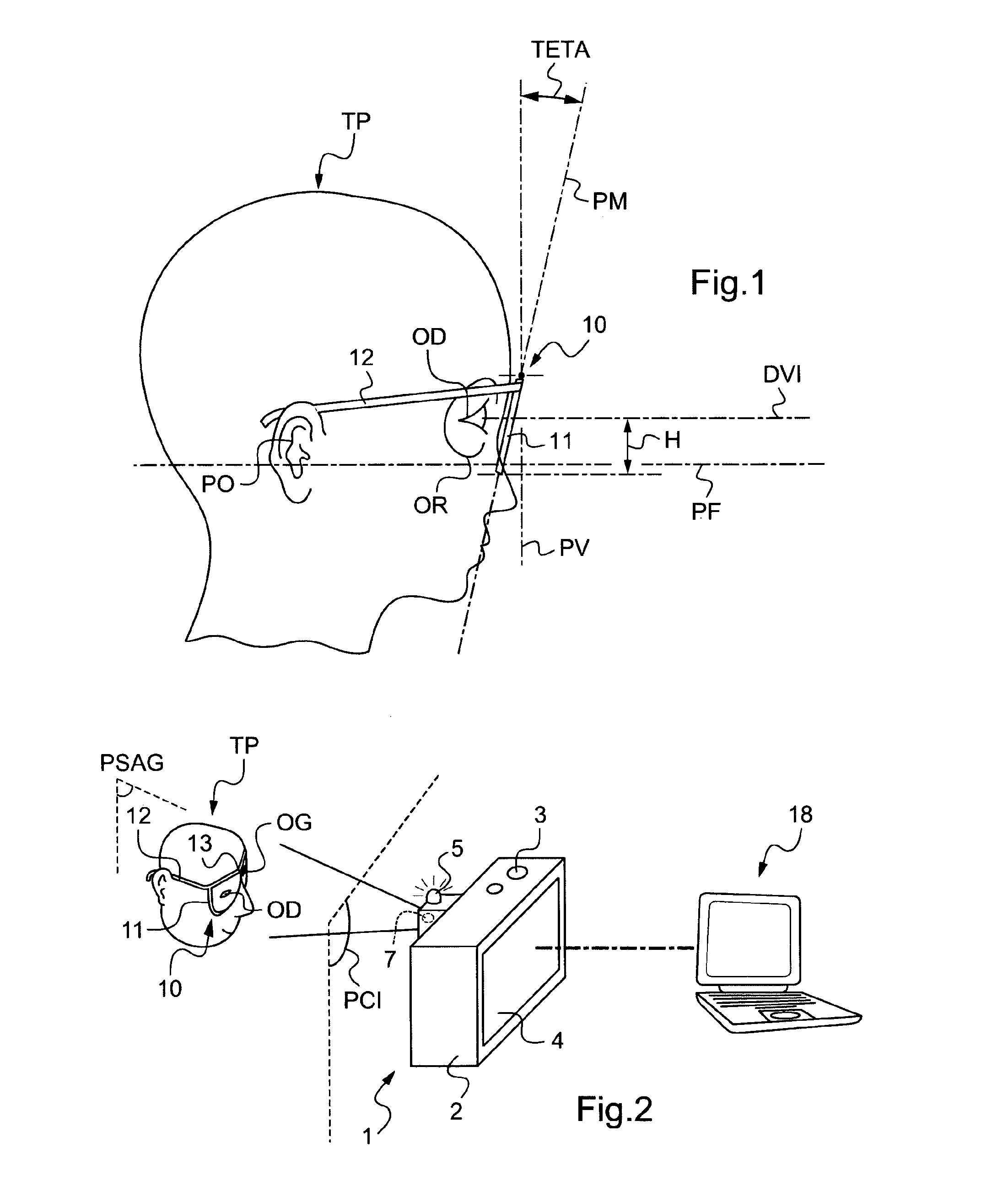

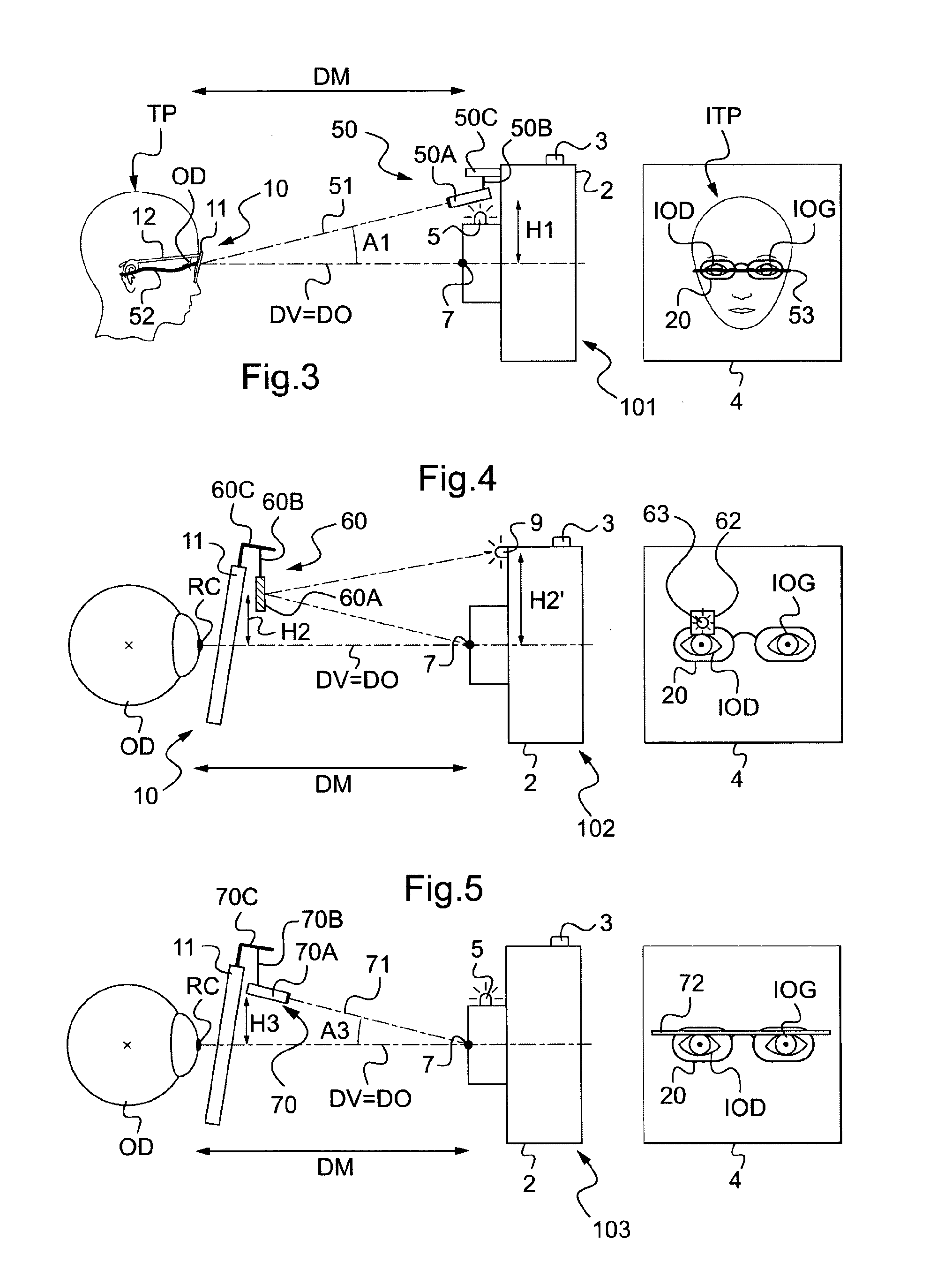

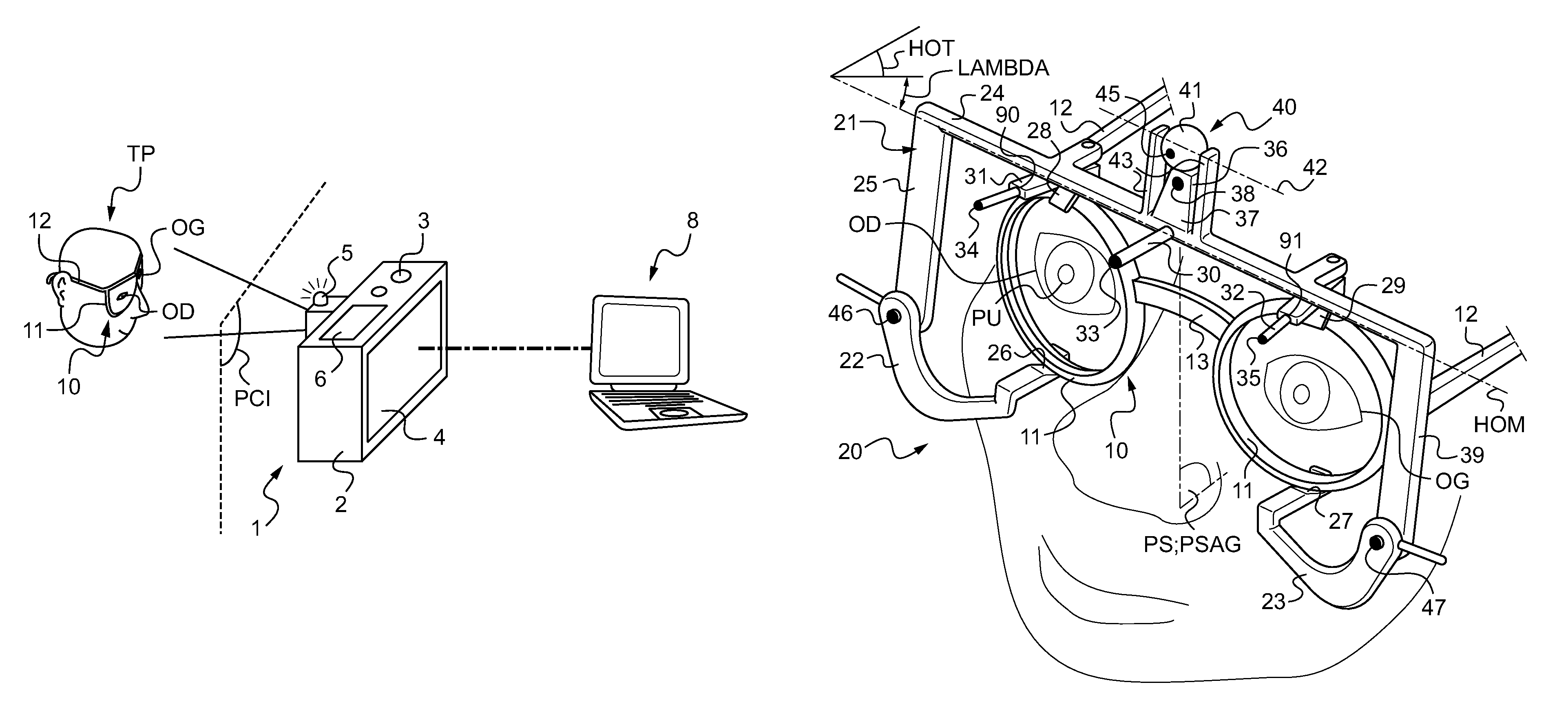

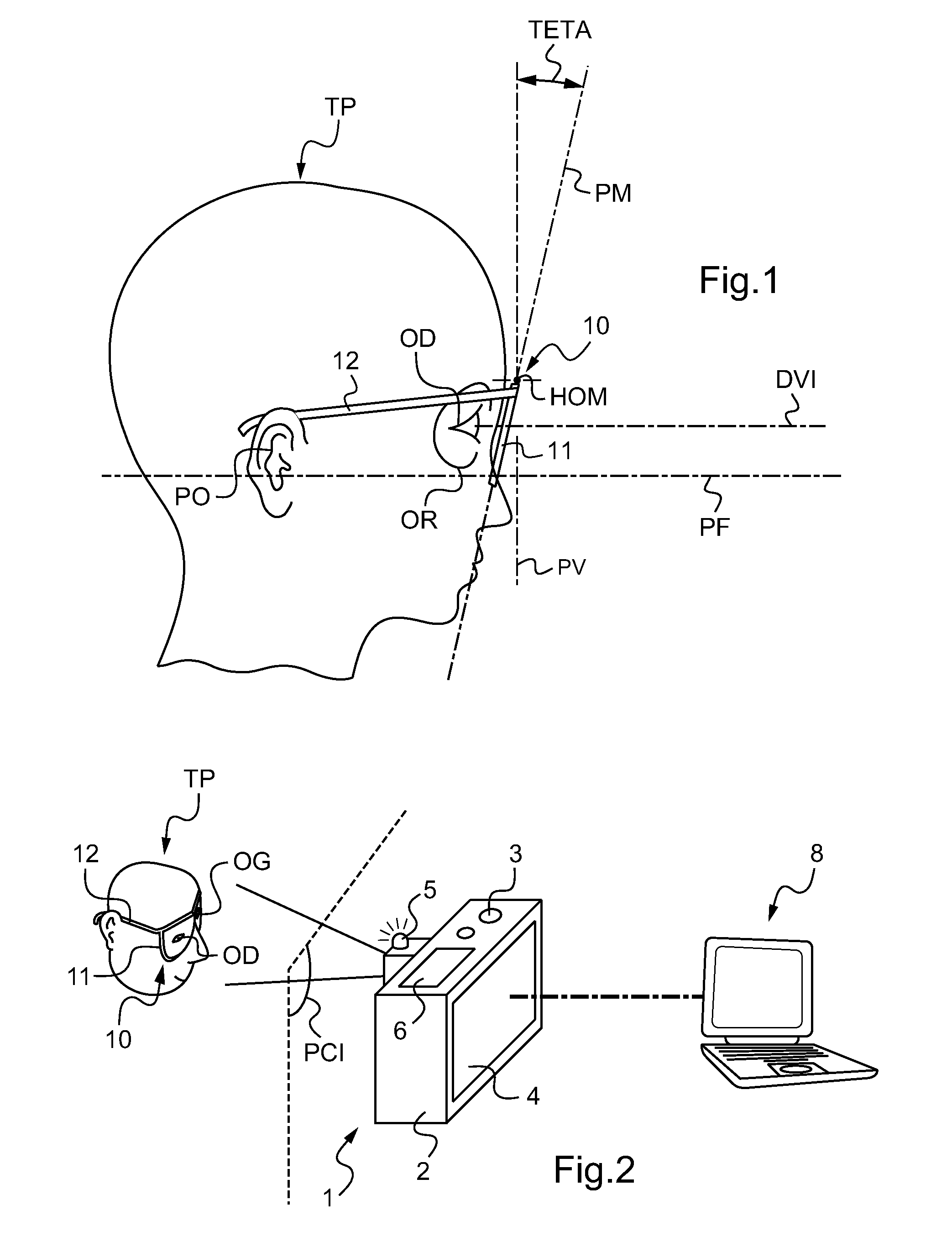

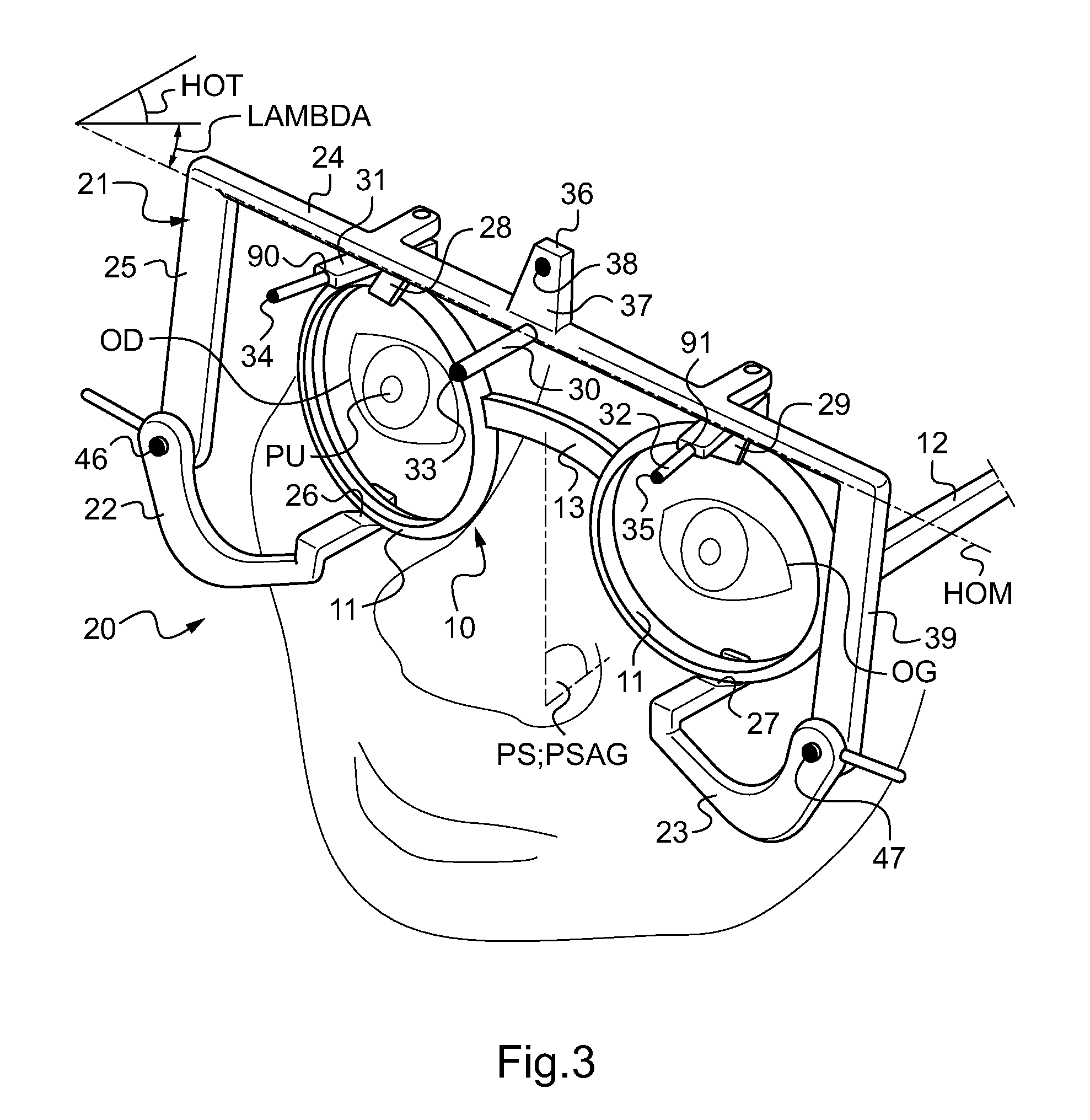

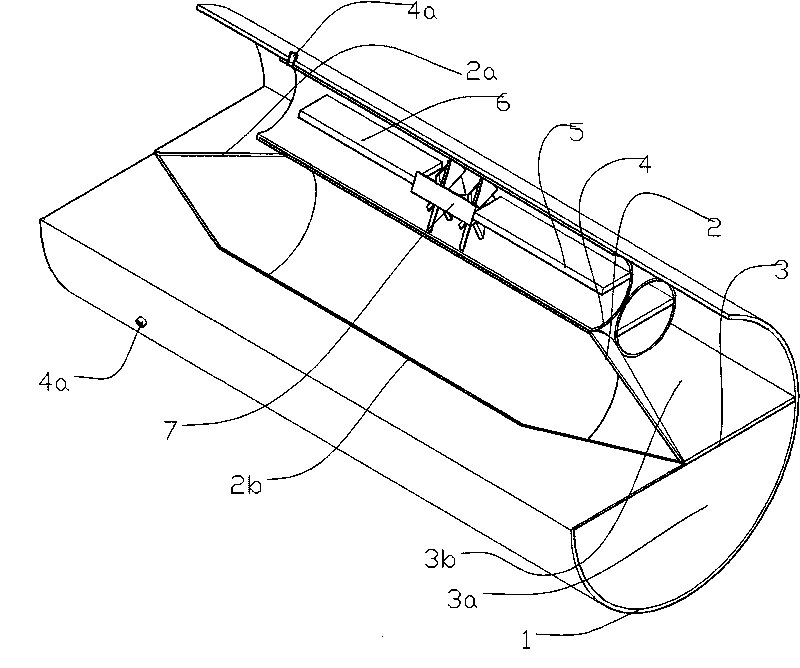

Method of measuring at least one geometrico-physionomic parameter for positioning a frame of vision-correcting eyeglasses on the face of a wearer

ActiveUS8231220B2Accurate measurementFlexible and fastSpectales/gogglesColor television detailsPupilDigital image

The method includes capturing at least one digital image of the wearer's face with a portable image capture appliance (1) and processing the captured image to determine a geometrico-physionomic parameter. Before capturing the image, the operator positions the image capture appliance manually in a first configuration in which an observation line connecting the pupil (7) of the image capture appliance with a predetermined remarkable point associated with the wearer's face or with the frame is substantially horizontal. Image capture is performed in a second configuration of the image capture appliance such that the altitude of the image capture appliance is identical to its altitude in the first configuration. The calculation of the geometrico-physionomic parameter includes identifying on the image, the image of the predetermined remarkable point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

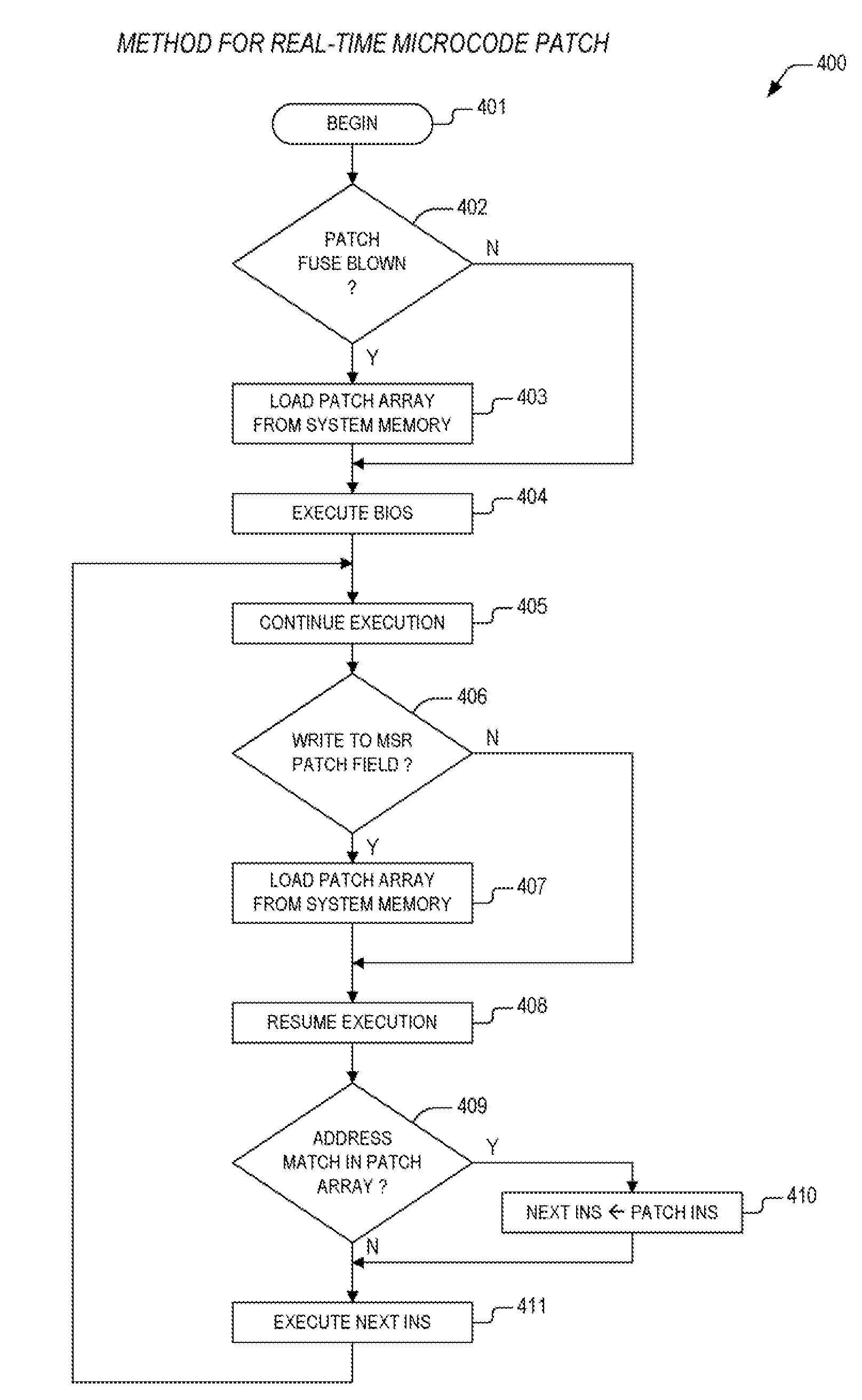

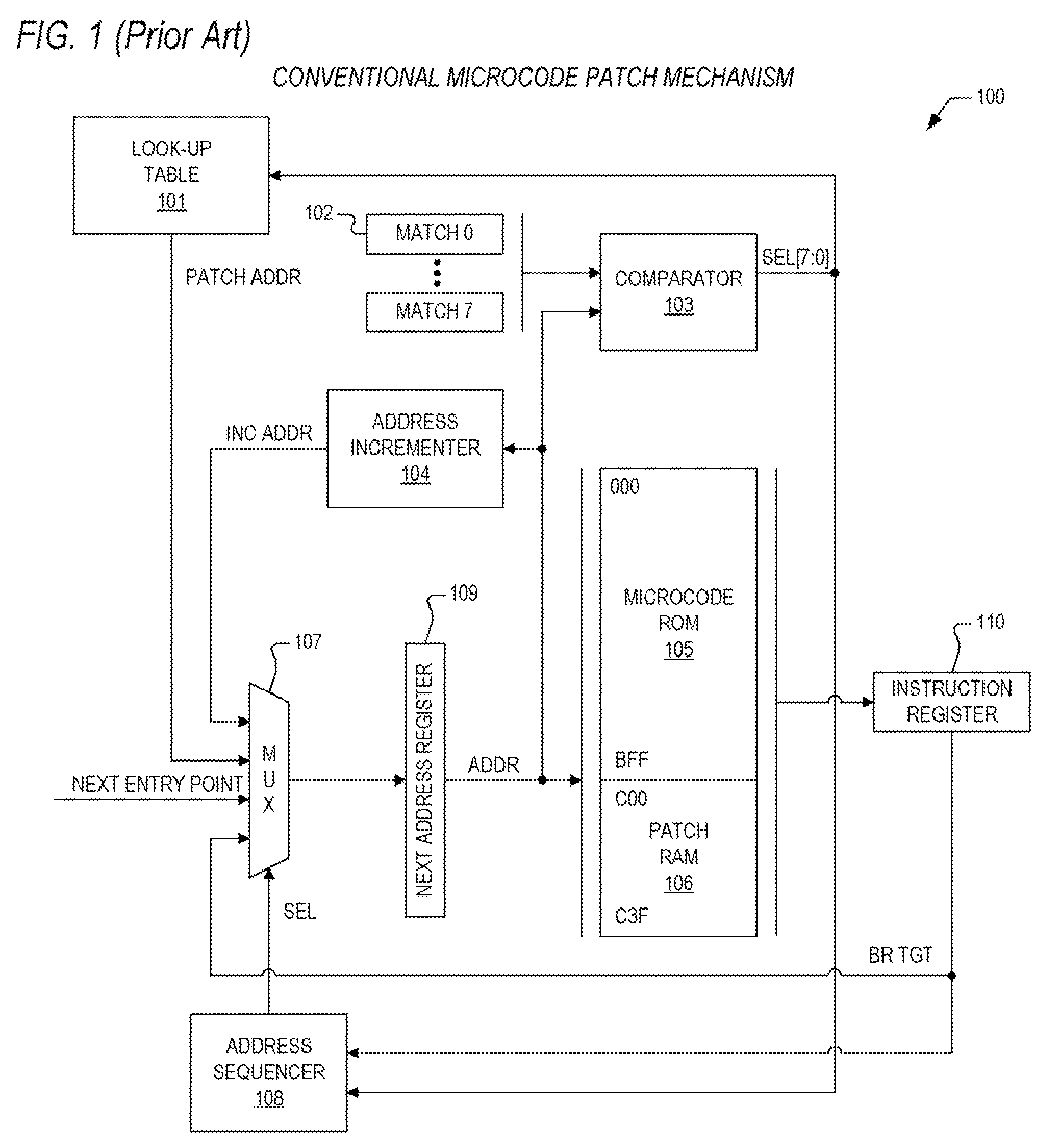

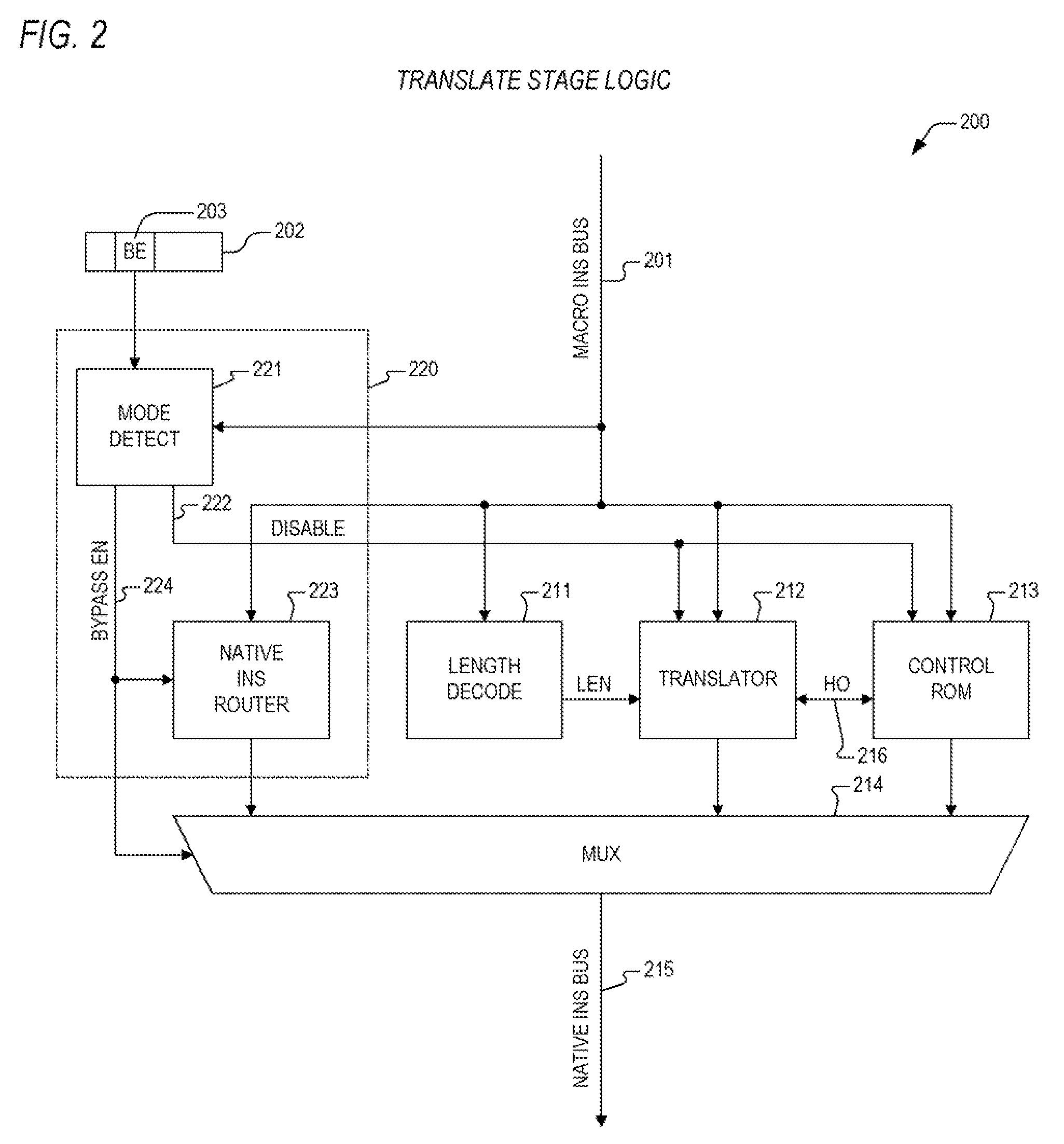

Apparatus and method for real-time microcode patch

InactiveUS20090031121A1Flexible and fastInstruction analysisDigital computer detailsPatch arrayOperating system

An apparatus for performing microcode patches that is both fast and flexible. In one embodiment, an apparatus for performing a real-time microcode patch is provided. The apparatus includes a patch array and a mux. The patch array receives a microcode ROM address and determines that the microcode ROM address matches one of a plurality of entries within the patch array. When the microcode ROM address matches, the patch array outputs a corresponding patch instruction and to assert a hit signal. The mux receives the patch instruction from the patch array and a micro instruction corresponding to the microcode ROM address from a microcode ROM. The mux provides the micro instruction or the corresponding patch instruction to an instruction register based upon the state of the hit signal.

Owner:VIA TECH INC

Method of measuring at least one geometrico-physionomic parameter for positioning a frame of vision-correcting eyeglasses on the face of a wearer

ActiveUS20100177186A1Accurate measurementFlexible and fastSpectales/gogglesColor television detailsPupilDigital image

The method includes capturing at least one digital image of the wearer's face with a portable image capture appliance (1) and processing the captured image to determine a geometrico-physionomic parameter. Before capturing the image, the operator positions the image capture appliance manually in a first configuration in which an observation line connecting the pupil (7) of the image capture appliance with a predetermined remarkable point associated with the wearer's face or with the frame is substantially horizontal. Image capture is performed in a second configuration of the image capture appliance such that the altitude of the image capture appliance is identical to its altitude in the first configuration. The calculation of the geometrico-physionomic parameter includes identifying on the image, the image of the predetermined remarkable point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Method of measuring at least one geometrico-physiognomic parameter for positioning a vision correcting eyeglass frame on the face of a wearer

ActiveUS7950800B2Flexible and fastHigh measurement accuracySpectales/gogglesEye diagnosticsComputer graphics (images)Radiology

A method of capturing a substantially front-view image of the face of a wearer wearing at least one frame (10), the image being captured by an image-capture appliance (1), and calculating the geometrico-physiognomic parameter (H, TETA) by processing the captured image. The calculation of the geometrico-physiognomic parameter (H, TETA) includes identifying in the image the image of a predetermined remarkable point (RC) that is directly or indirectly associated with the wearer's face or with the frame, and it takes into consideration a magnitude representative of the absolute vertical angle of observation (GAMMA) formed between firstly an observation line (DO) connecting the pupil (7) of the image-capture appliance (1) to the remarkable point (RC), and secondly its projection onto a horizontal plane (PF).

Owner:ESSILOR INT CIE GEN DOPTIQUE

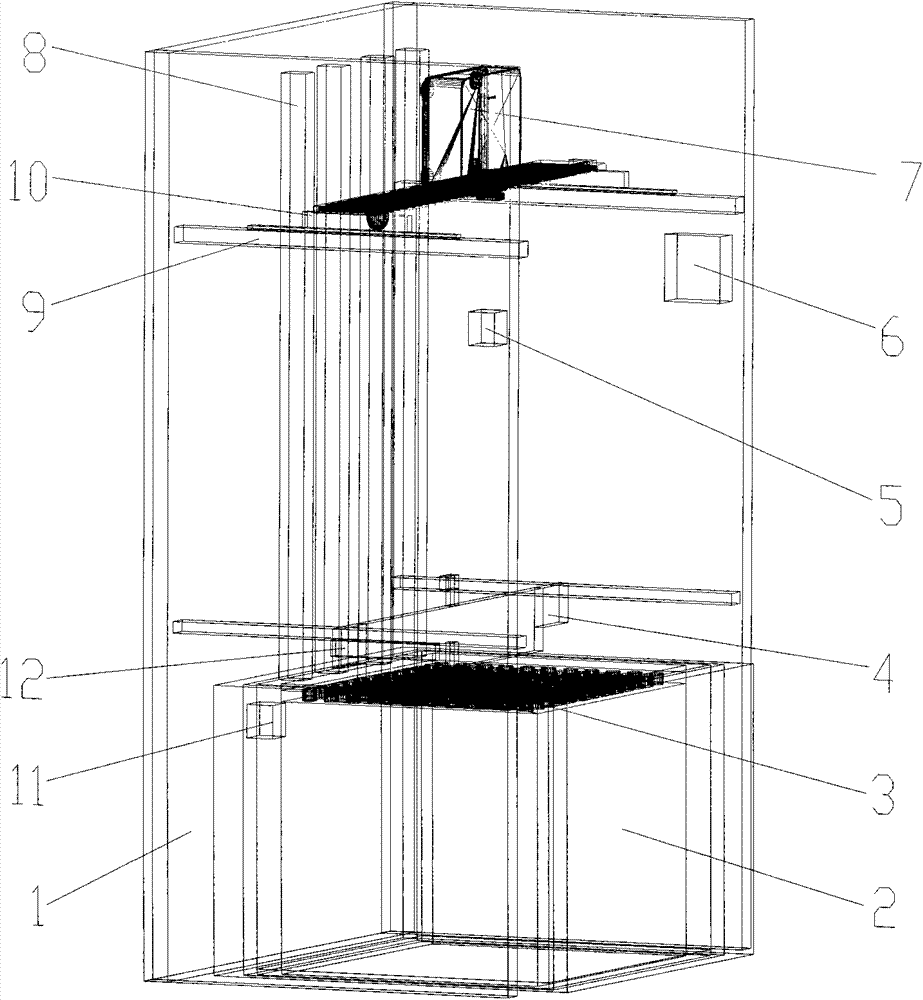

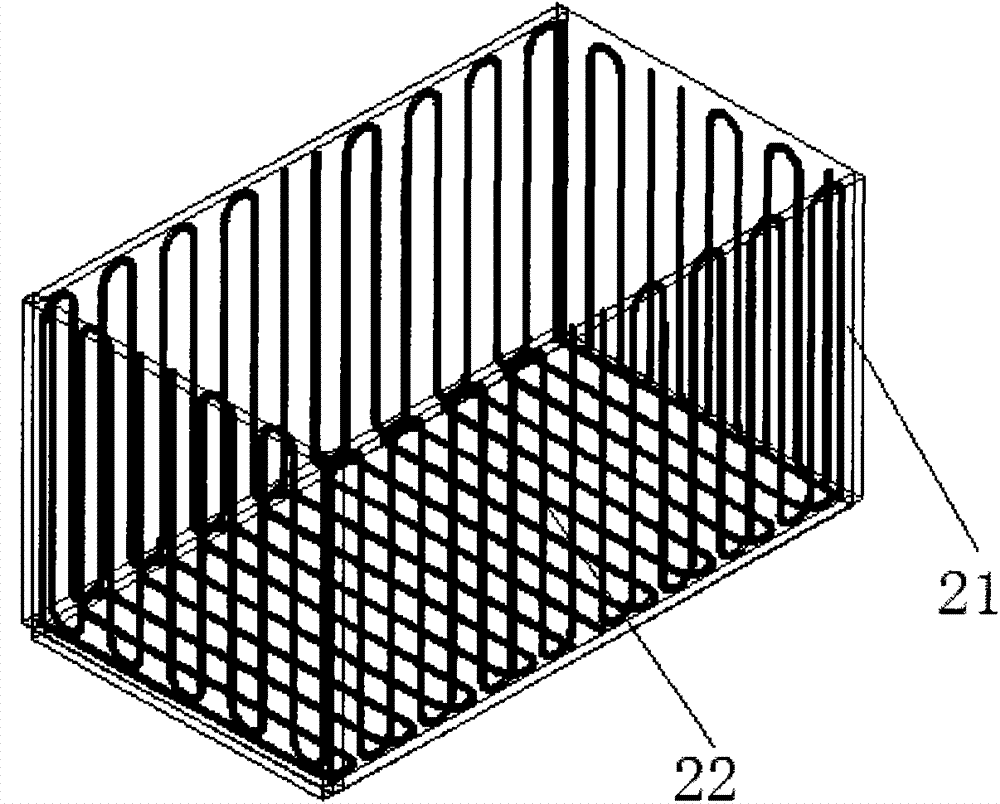

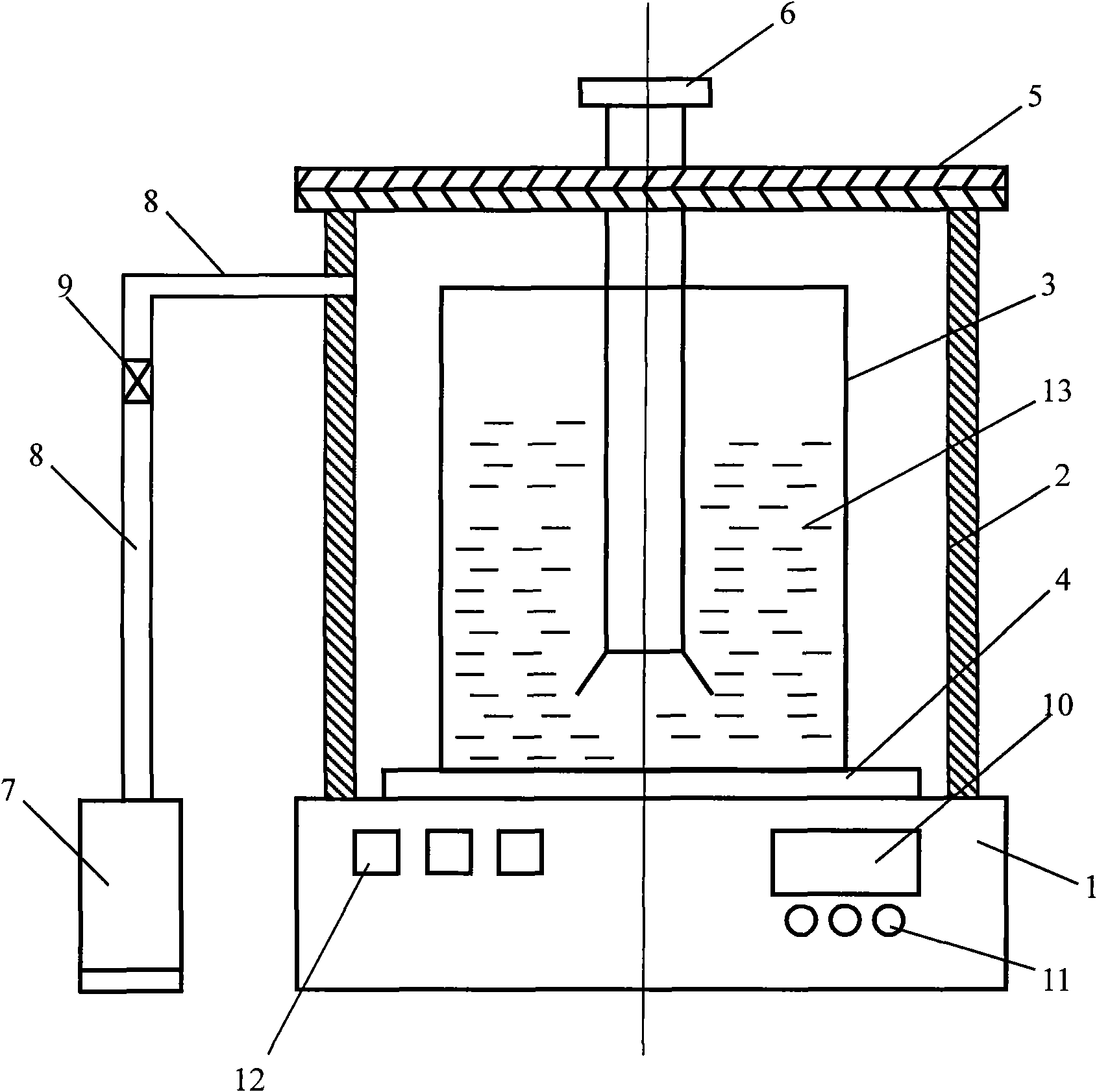

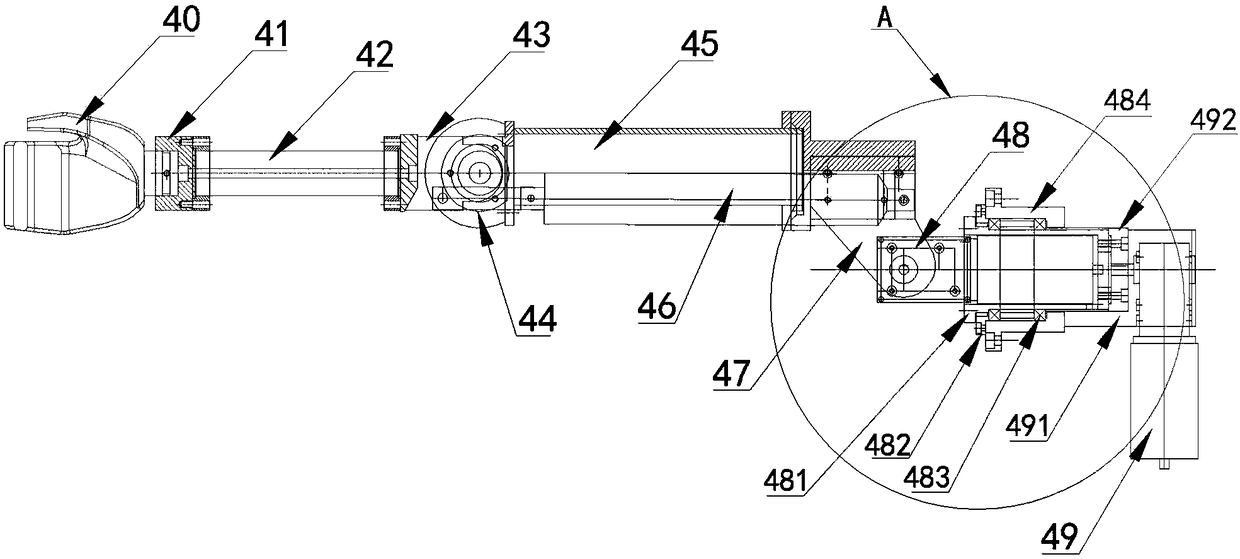

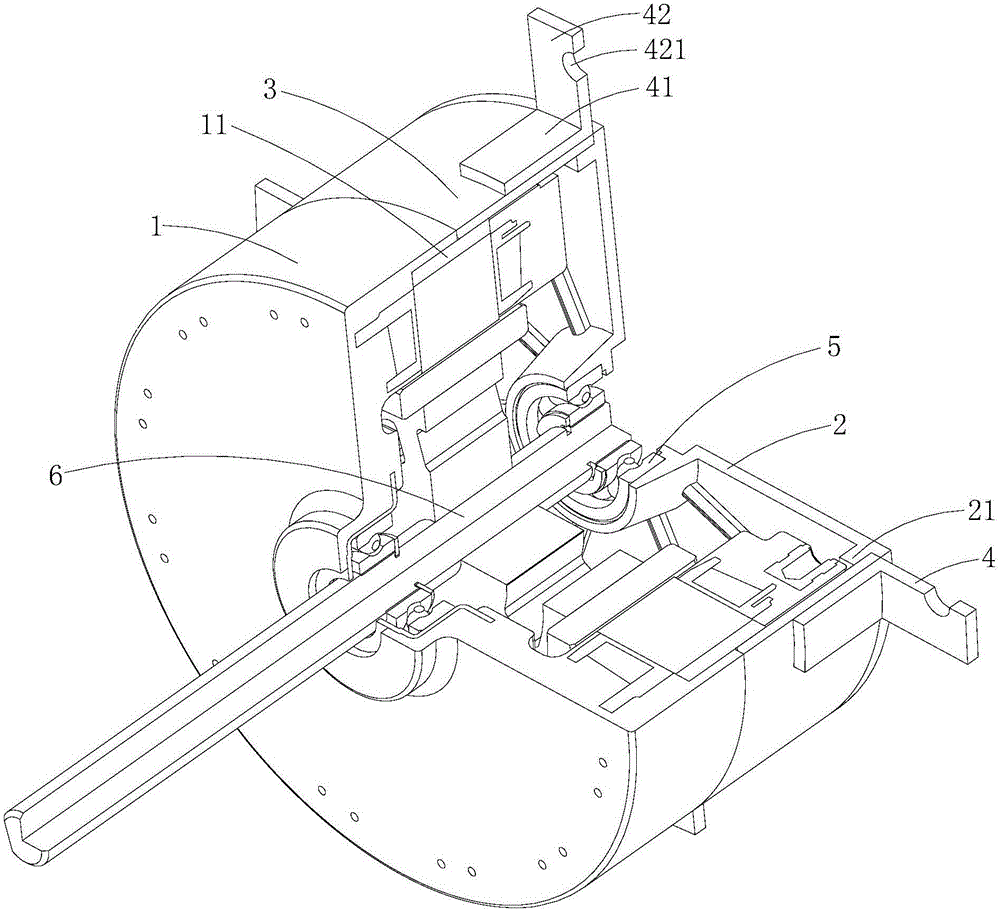

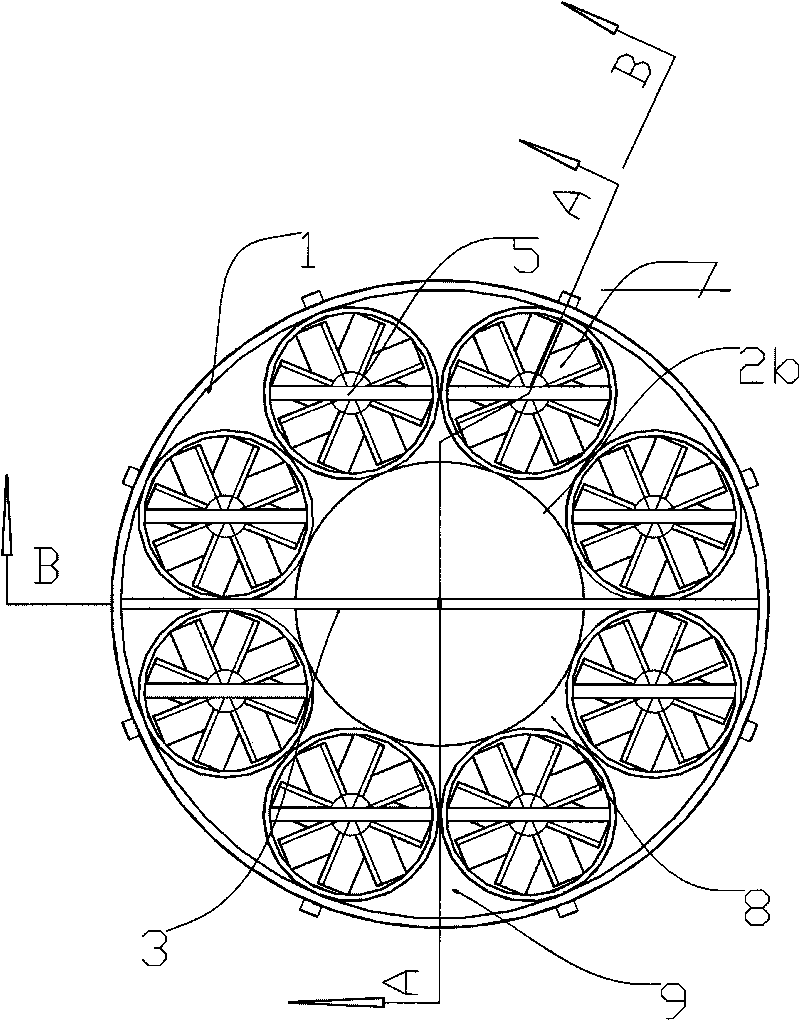

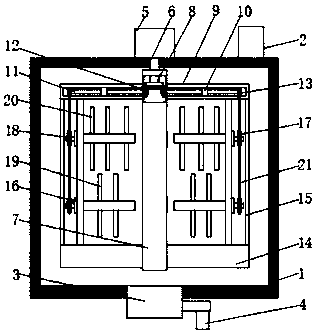

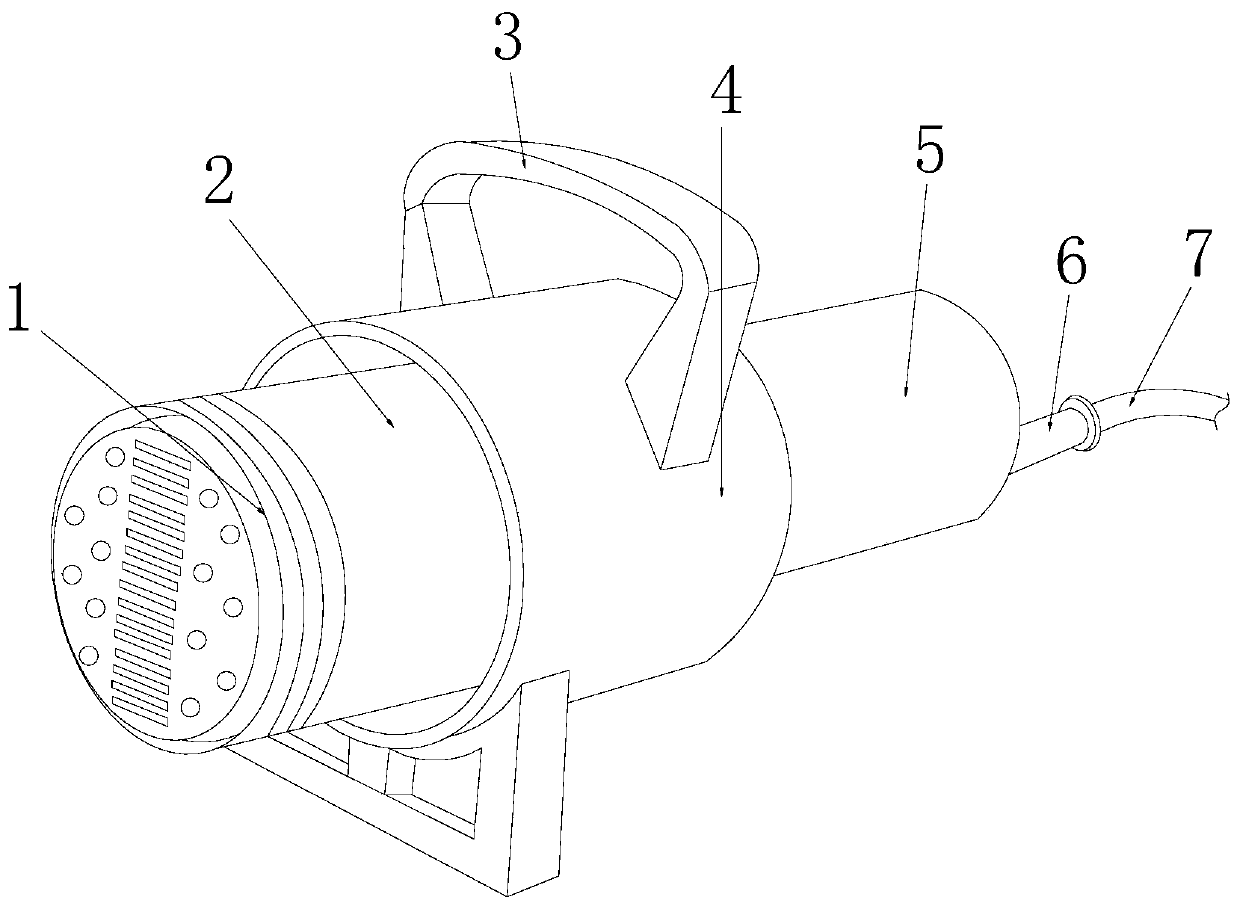

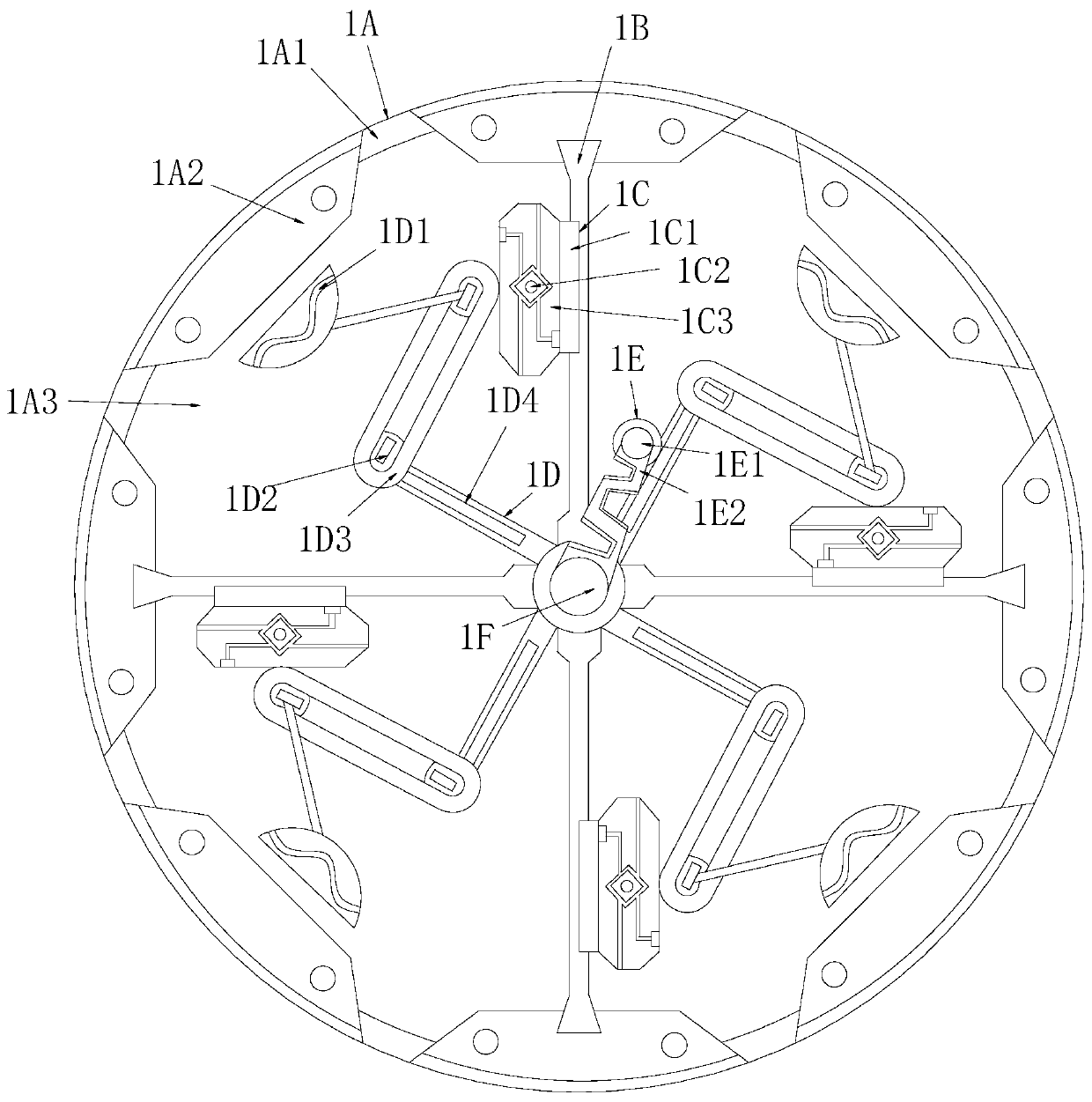

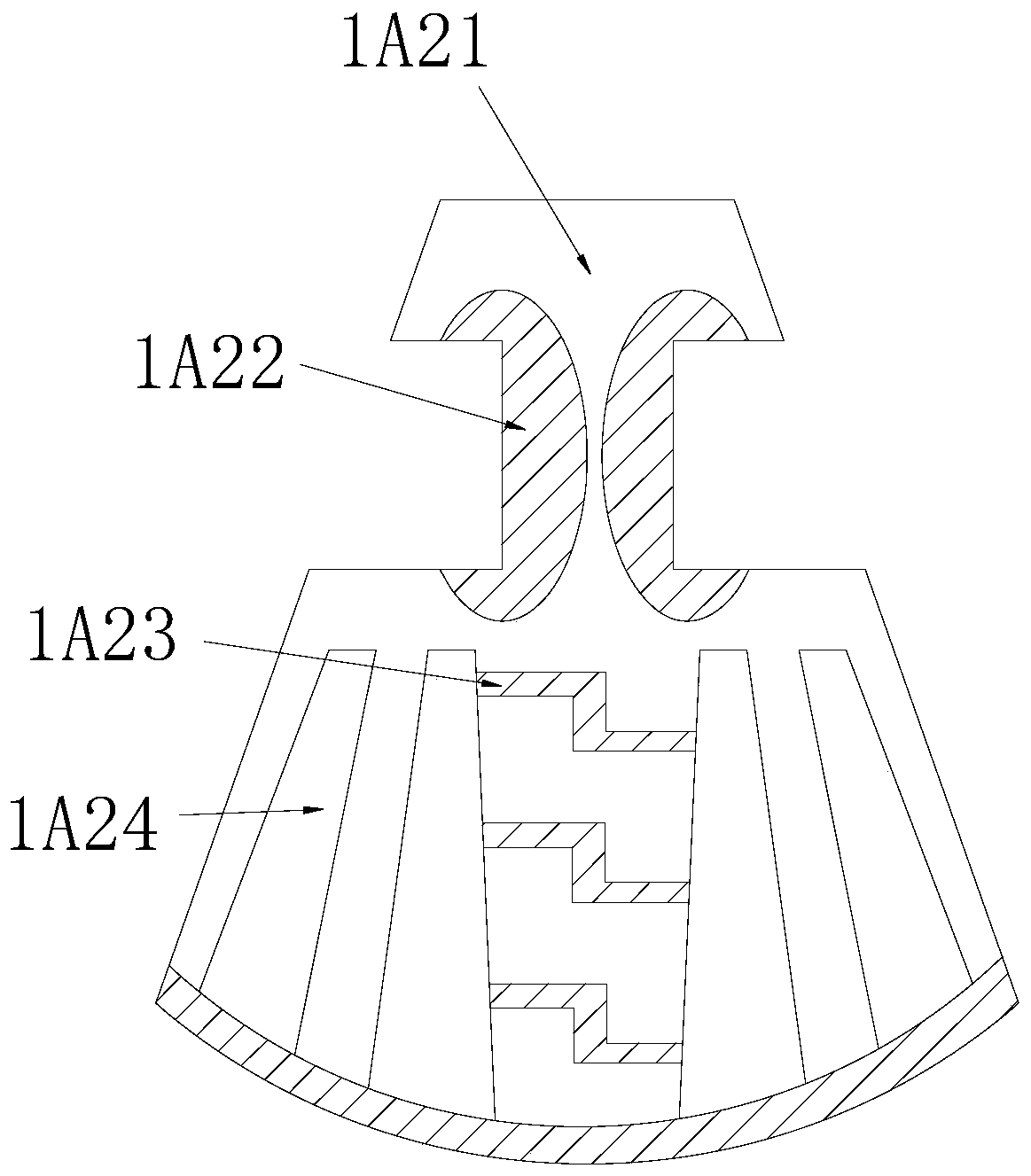

Light-source movable type area-forming three-dimensional printing forming system

ActiveCN103935035AFlexible and fastOvercoming the defects of 3D printingTemperature controlControl system

The invention relates to a light-source movable type area-forming three-dimensional printing forming system. The system comprises a box body, and the box body is inside provided with a data processing control system, a transmission system, a movable type area imaging apparatus, a temperature-control liquid containing system, a printing forming platform and a sensor system. The beneficial effects comprise that the invention provides that light-source movable type area-forming three-dimensional printing forming system capable of performing three-dimensional model printing with a movable light source.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

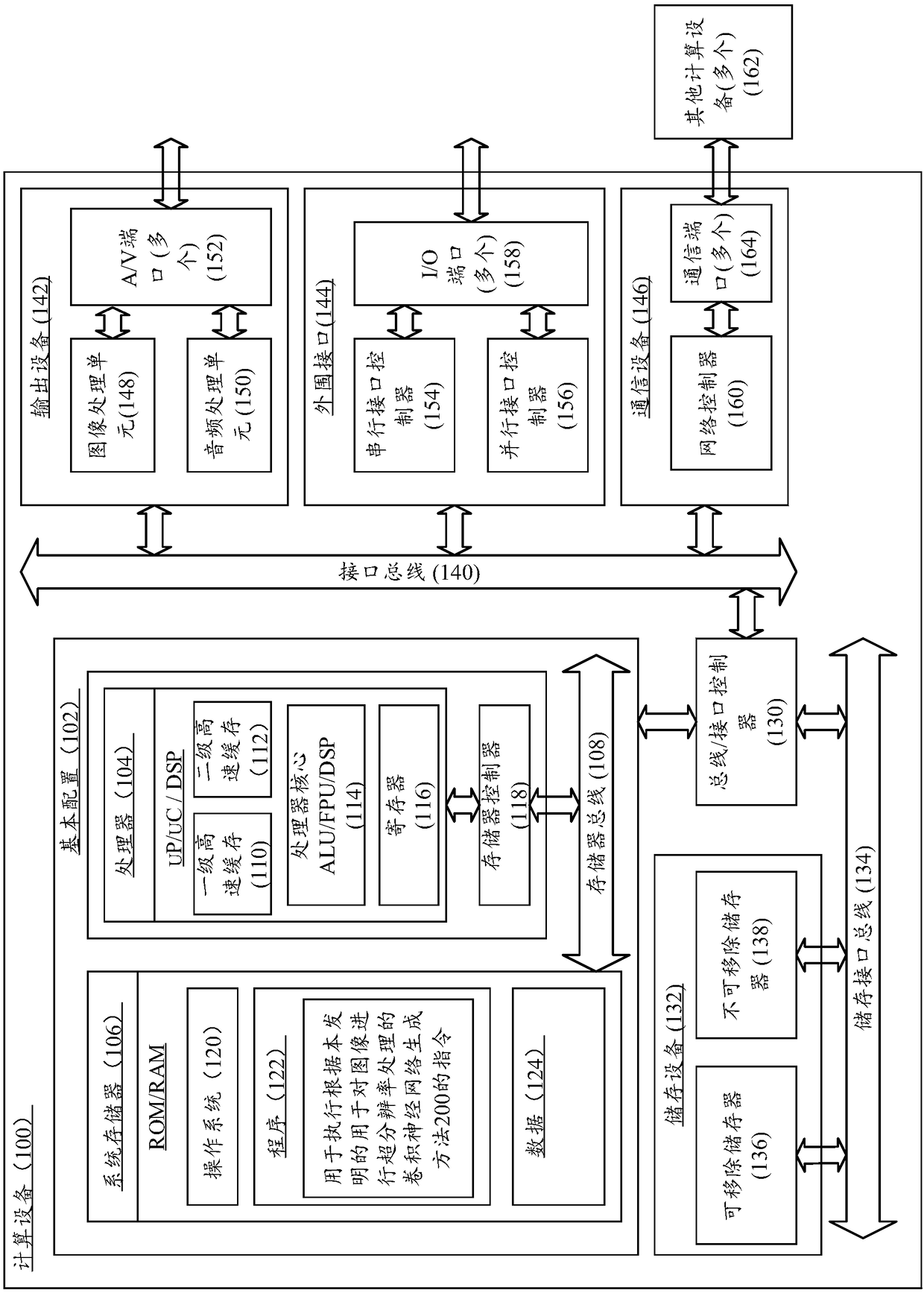

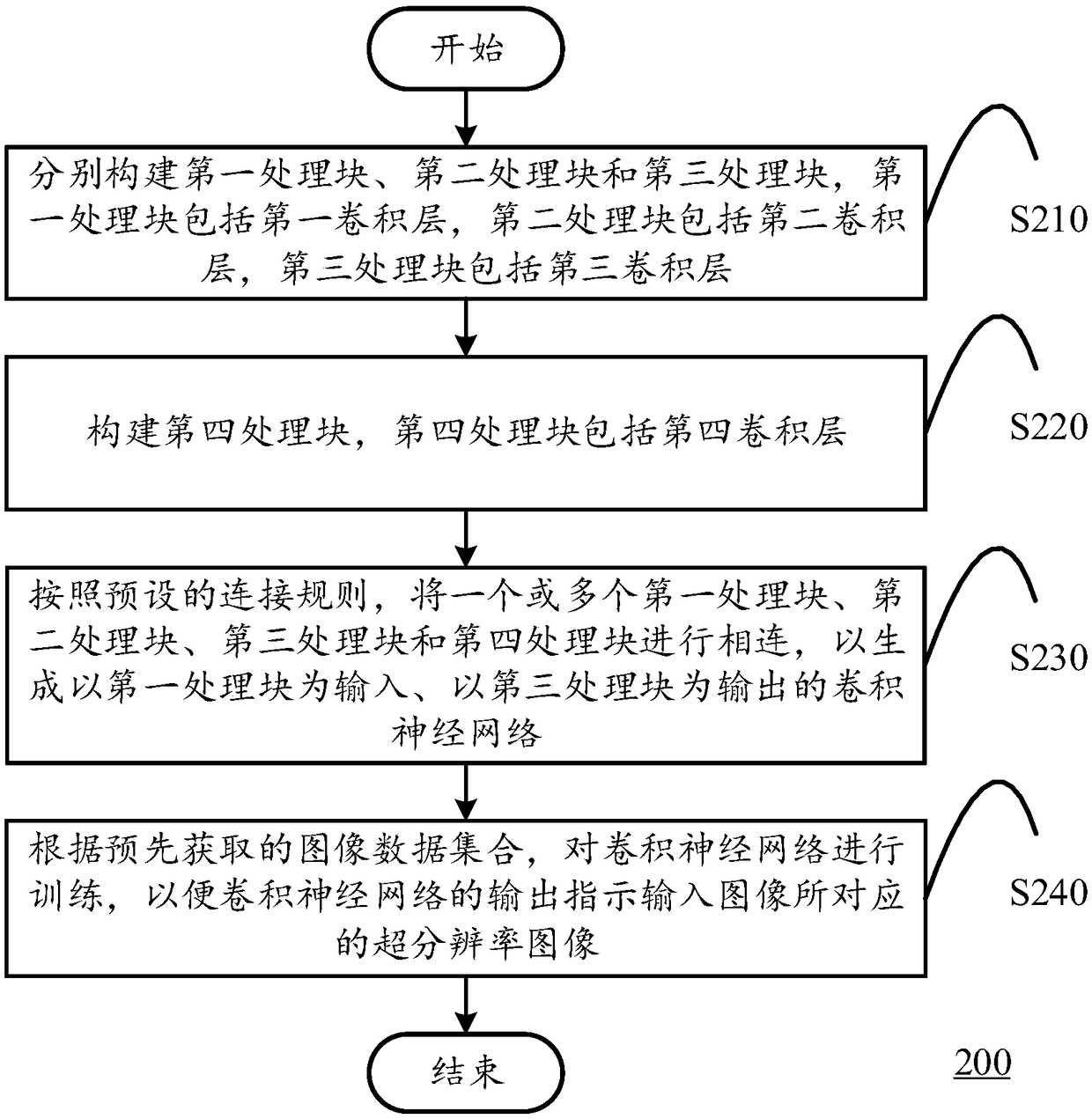

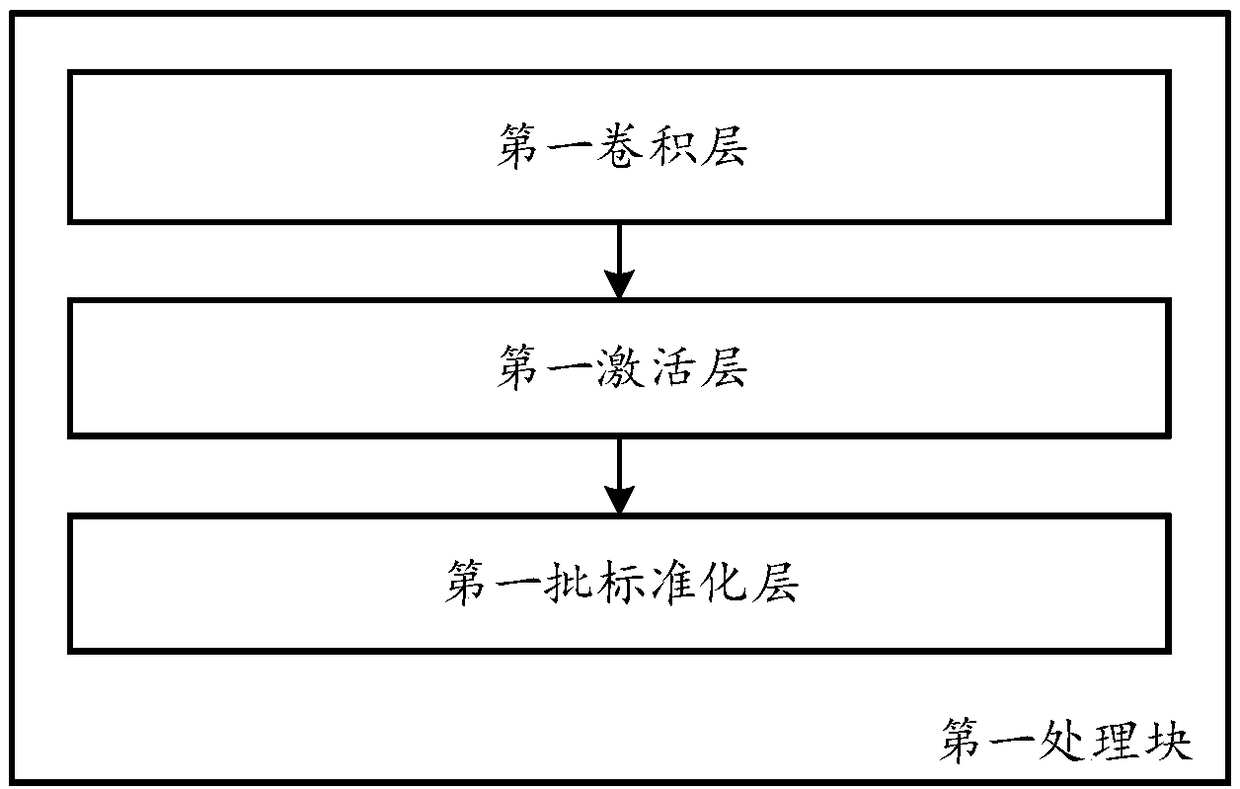

A convolution neural network generation method and a super-resolution method of an image

ActiveCN109360154AEasy to reinforceHigh speedGeometric image transformationNeural architecturesData setAlgorithm

The invention discloses a convolution neural network generation method for performing super-resolution processing on an image, and a super-resolution method of an image, a computing device and a mobile terminal. The convolution neural network generation method includes constructing a first processing block, a second processing block and a third processing block respectively, wherein the first processing block comprises a first convolutional layer, the second processing block comprises a second convolutional layer and the third processing block comprises a third convolutional layer; constructing a fourth processing block, the fourth processing block comprising a fourth convolution layer; connecting one or more first processing blocks, a second processing block, a third processing block anda fourth processing block according to a preset connection rule to generate a convolution neural network with the first processing block as an input and the third processing block as an output; according to the pre-acquired image data set, training the convolution neural network so that the output of the convolution neural network indicates the super-resolution image corresponding to the input image.

Owner:XIAMEN MEITUZHIJIA TECH

Traffic matrix estimation method and apparatus

InactiveUS7574506B1Reduce dimensionalityPromote resultsDigital computer detailsData switching networksMatrix estimationReal-time computing

Owner:AT&T INTPROP II L P

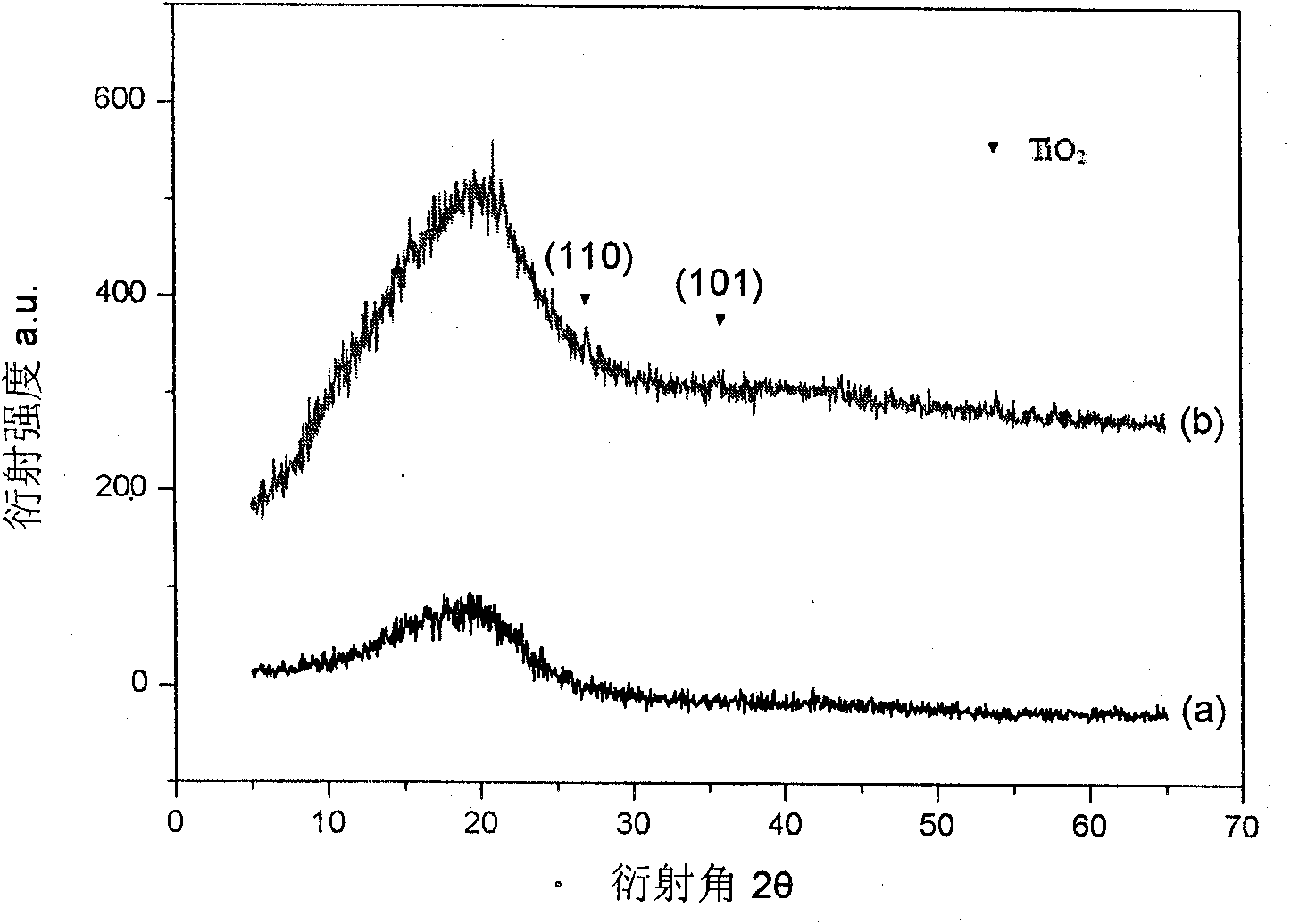

Preparation method of plugging composite material polyurethane elastomer used in coal mines

The invention relates to a preparation method of plugging composite material polyurethane elastomer used in coal mines, and the method comprises the following steps: taking modified nano titanium dioxide, polyether polyalcohol, toluene diisocyanate and the like as raw materials; synthesizing respectively component A yellow transparent liquid product and component B white opaque liquid product in a reaction kettle test jar under the state of vacuum, heating and stirring; stirring and blending with the ratio of 4:6 when in use; spraying or brushing the plugged object; and solidifying after drying. The invention has the advantages of good plugging effect, good cohesive force, high rigidity, high temperature and low temperature resistance, aging resistance, good elasticity, shock absorption, acid resistance, oil resistance, water resistance, anti-static ability, tight padding, good insulation and good compactness; the invention can rapidly plug leaking water, leaking gas, leaking oil and cracks; the invention has rapid drying speed, after plugging by synthesization of component A and component B, drying and solidification can be completed in 120 min, and the thickness of the solidification layer can reach 4mm; the preparation method has short process flow and reasonable ratio, and can be applicable to building, petroleum and chemical industries.

Owner:山西先导科技开发有限公司

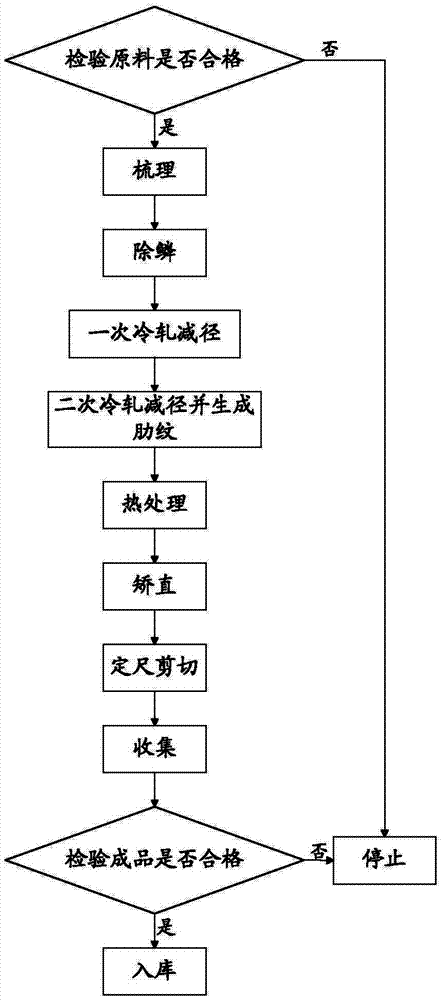

Processing technology of cold-rolled steel bar

The invention discloses a processing technology of a cold-rolled steel bar. The processing technology comprises the steps that 1) a hot-rolled wire rod is fed into a rolling mill unit to be subjected to reducing cold rolling to form rib patterns; 2) the hot-rolled wire rod after the cold rolling in the step 1) is subjected to heat treatment; and 3) the hot-rolled wire rod after the heat treatment in the step 2) is straightened, and then is subjected to length-given cutting and collected. The processing technology of the cold-rolled steel bar takes the hot-rolled wire rod as the raw material for production, a cold-rolled ribbed steel bar is formed through repeated cold rolling reducing and one-time rib pressing on the hot-rolled wire rod, and the internal stress generated in a cold rolling process is eliminated through the heat treatment on the cold-rolled ribbed steel bar, so that the elongation percentage and tensile strength of the finished cold-rolled steel bar are increased and improved. Compared with the production technology taking steel blanks as the raw material in the prior art, the processing technology is simplified from the source, the production cycle can be shortened effectively, the production cost can be lowered, the hot-rolled wire rods of different diameters can be adopted for production according to the requirements of customers, and the production can be carried out quickly and flexibly to meet different requirements of the customers.

Owner:CHONGQING MAITUO TECH CO LTD

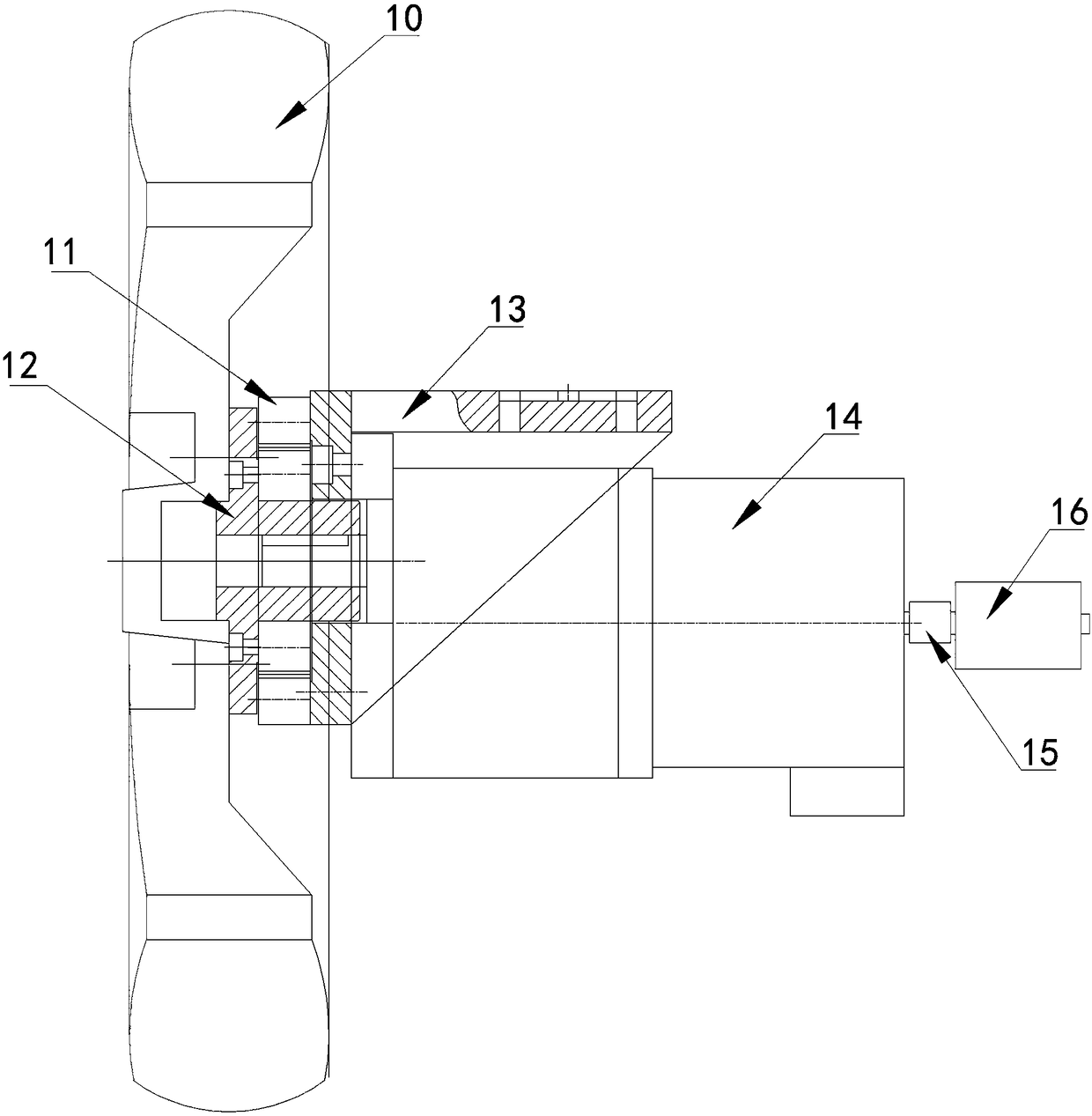

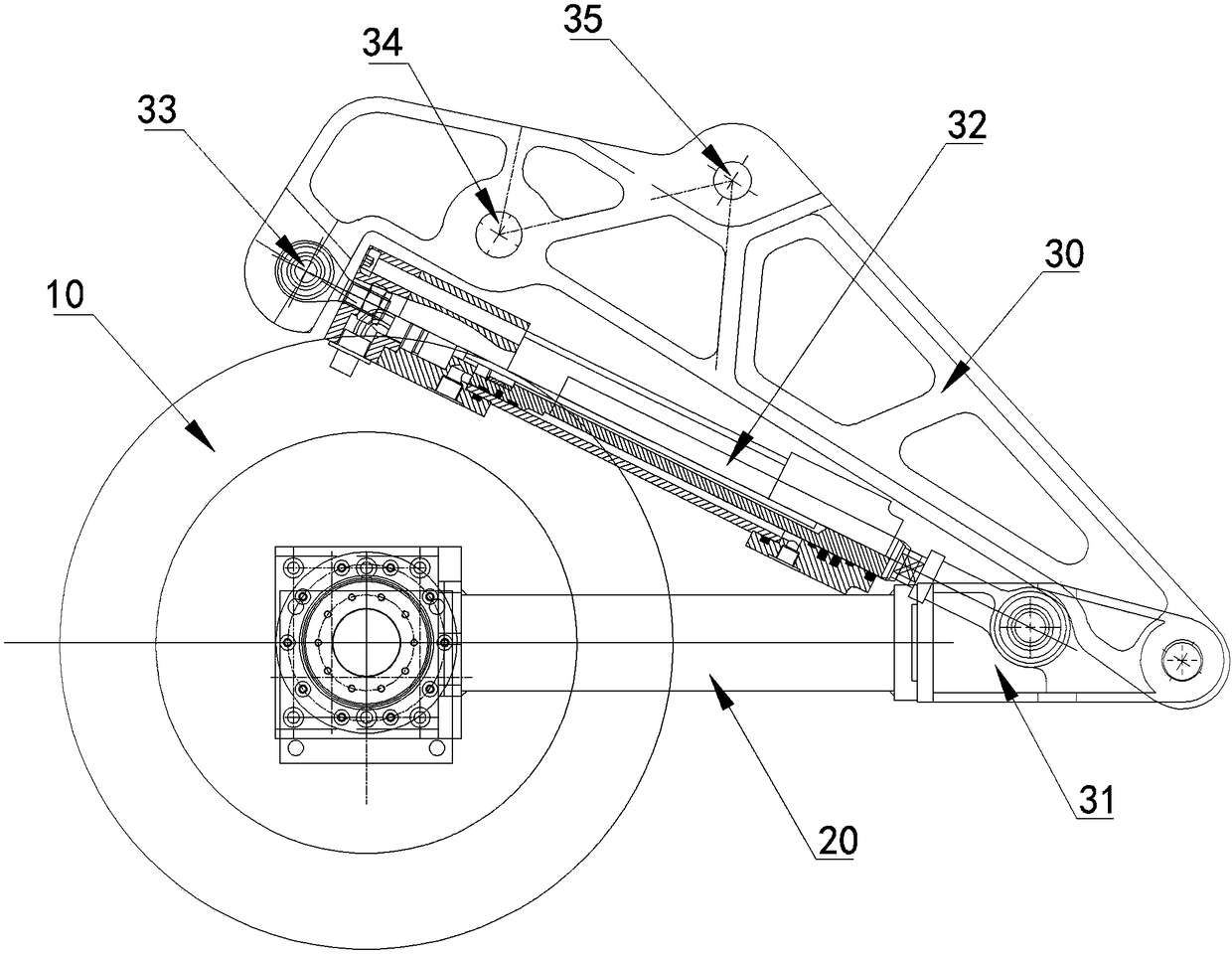

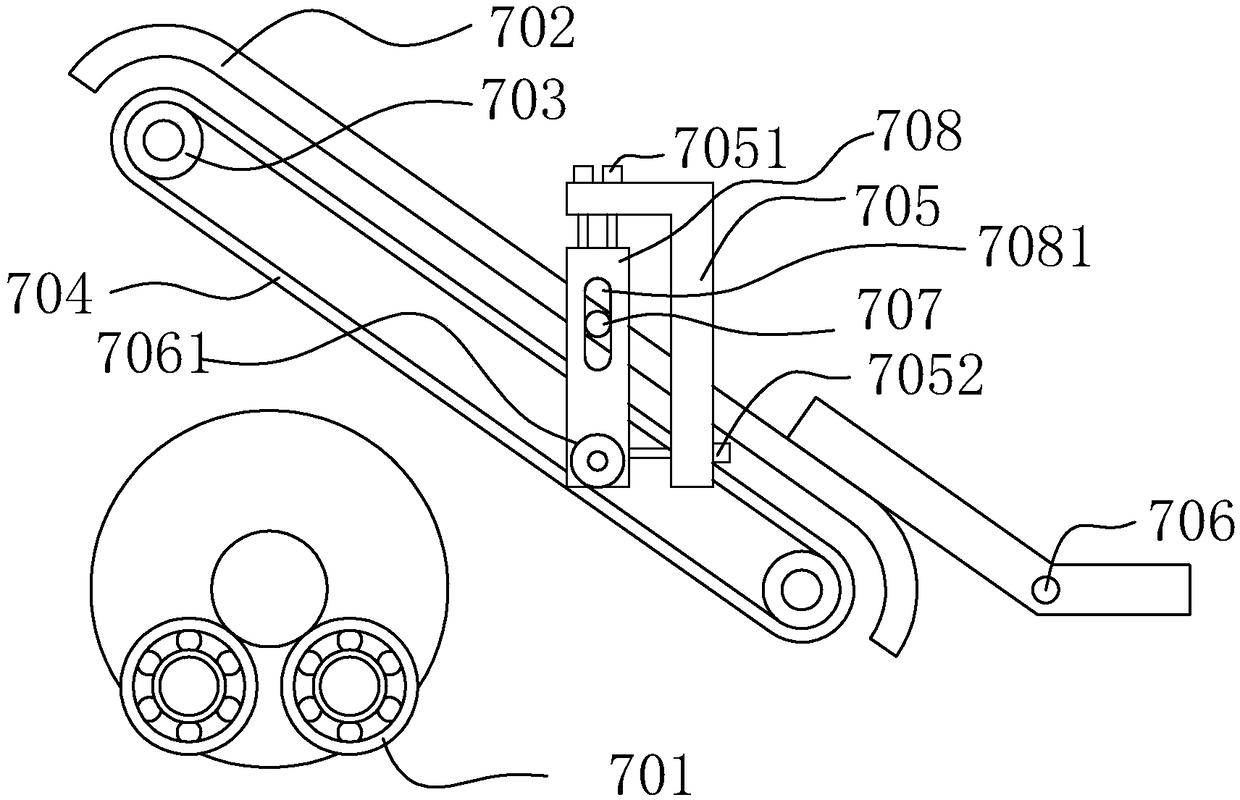

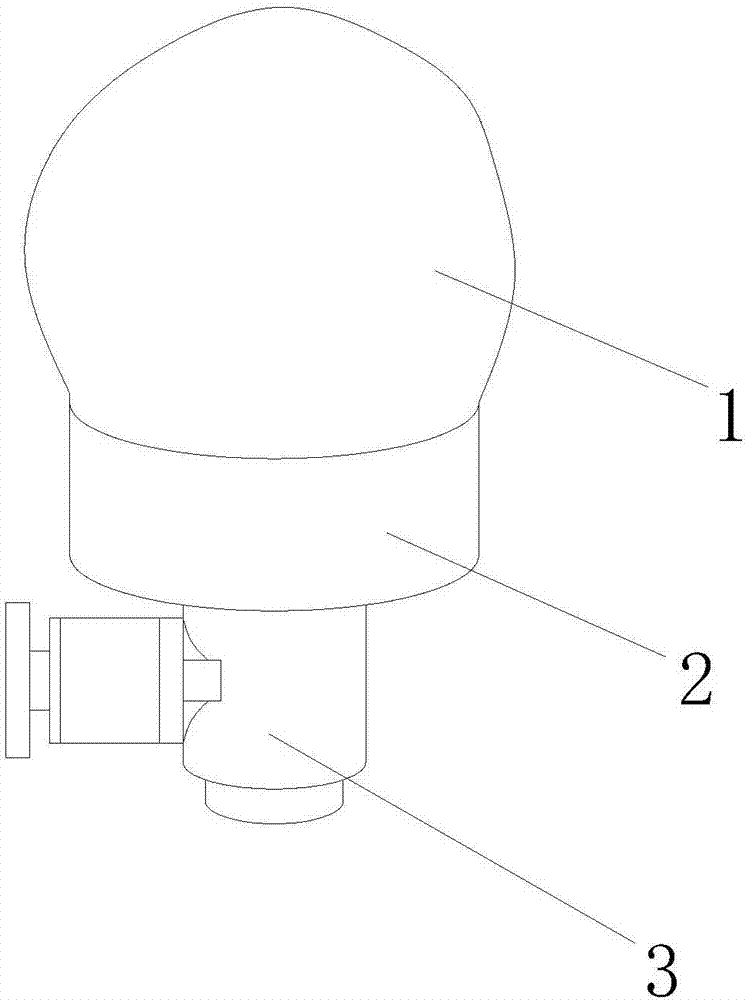

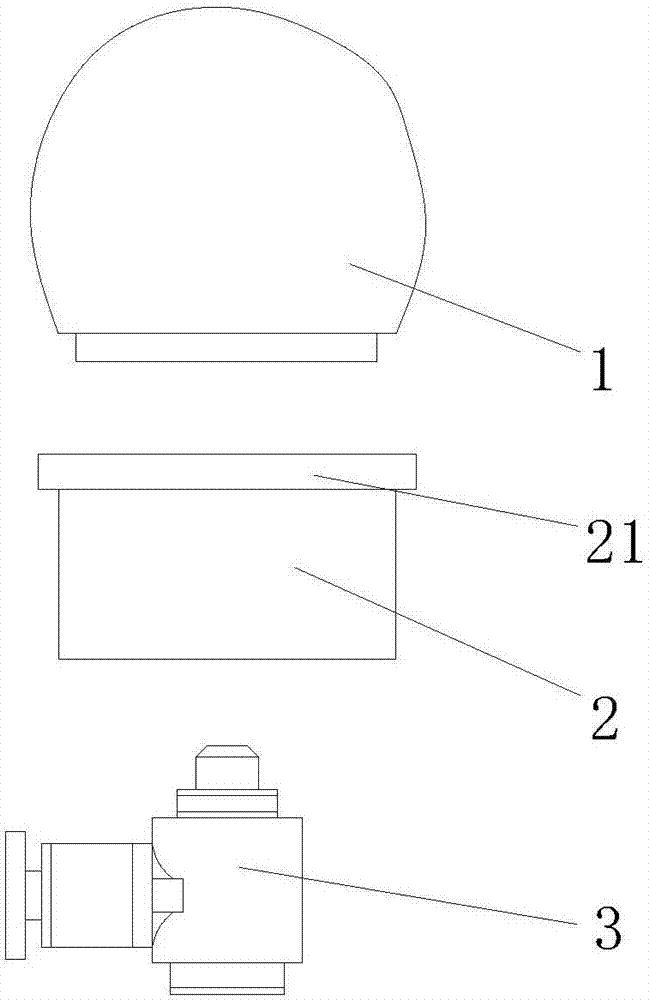

Wheel-legged robot

The invention discloses a wheel-legged robot, which comprises a control panel component, a wheel component, a leg component, a hand component, a hip motion component, a body balance part and a hydraulic system power component. The wheel component comprises a tire, a tire connection seat, a cross bearing, a brushless direct-current speed reducing motor, a coupler, an encoder and a shank connectionseat. The shank connection seat is connected with the tire connection seat which is provided with the tire, and the brushless direct-current speed reducing motor is provided with the coupler and the encoder and arranged on the tire connection seat. The leg component is arranged on the shank connection seat and comprises a shank rod, a thigh rod, a knee joint hinge seat and a leg oil cylinder component. The lower end of the thigh rod and the lower end of the leg oil cylinder component are connected with the upper end of the shank rod through the knee joint hinge seat, and the upper end of the thigh rod and the upper end of the leg oil cylinder component are both connected with the hip motion component. The wheel-legged robot is quick in action, high in flexibility and stability and capableof quickly moving at various activity places, and velocity efficiency is improved.

Owner:杭州欢乐飞机器人科技股份有限公司

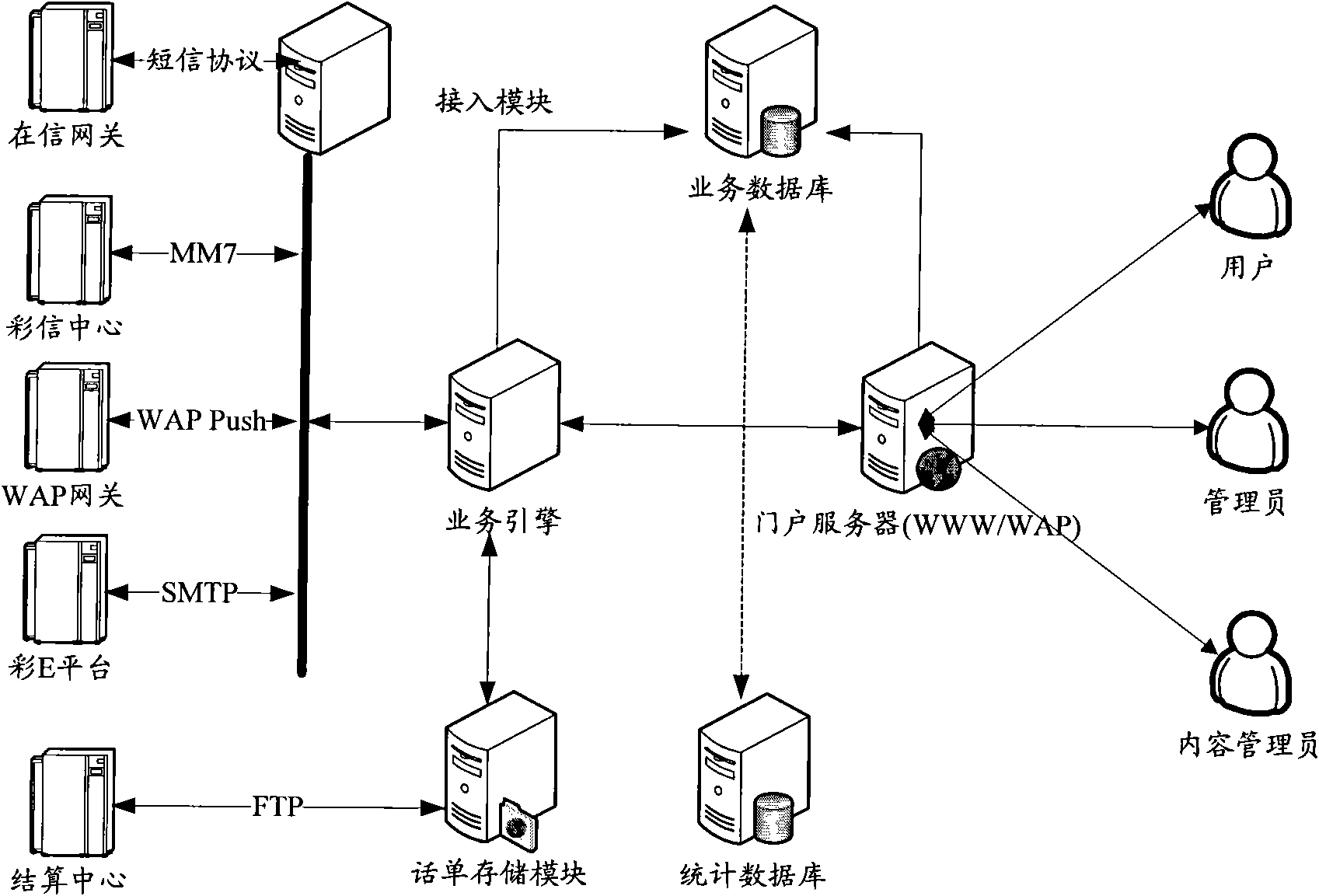

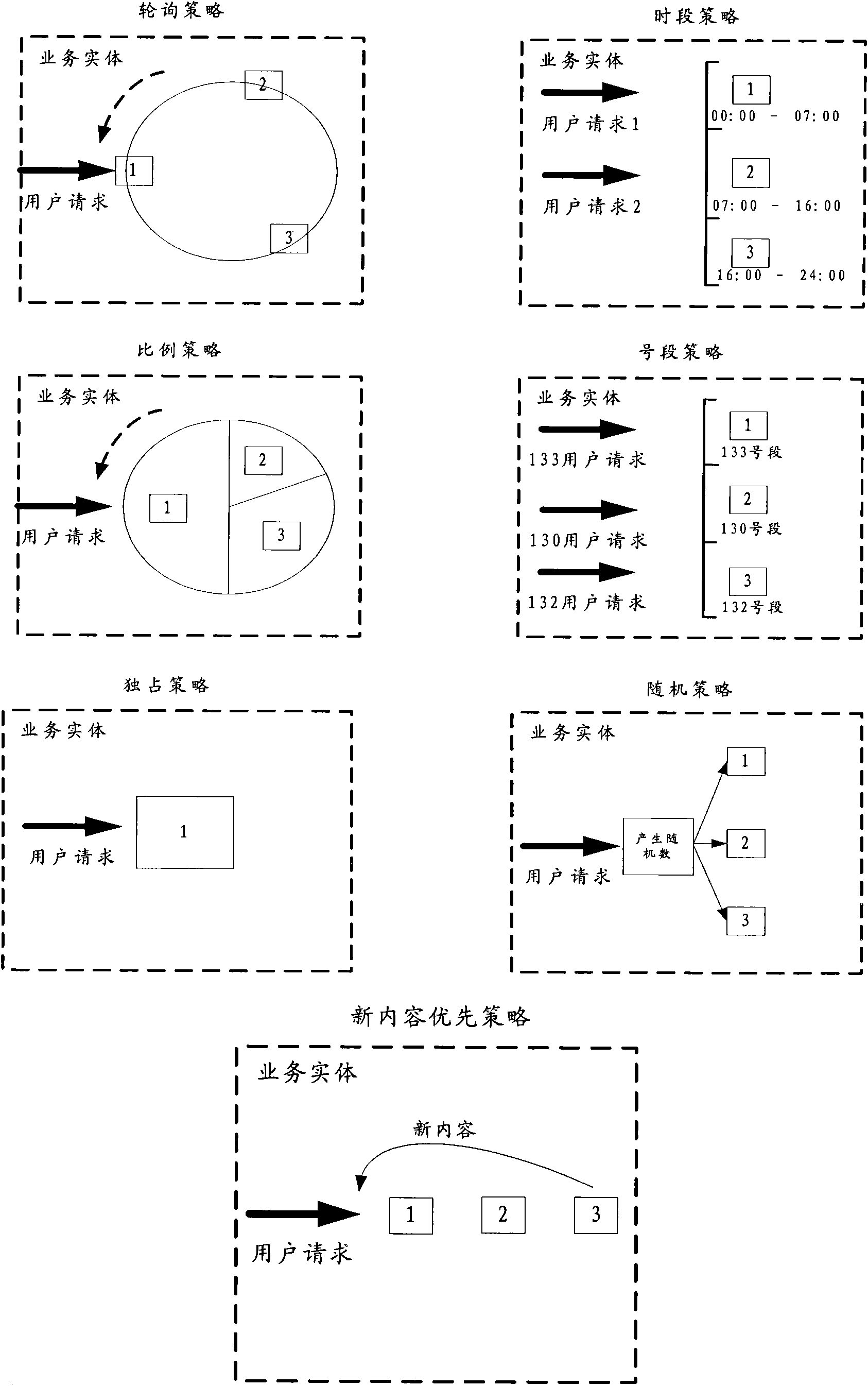

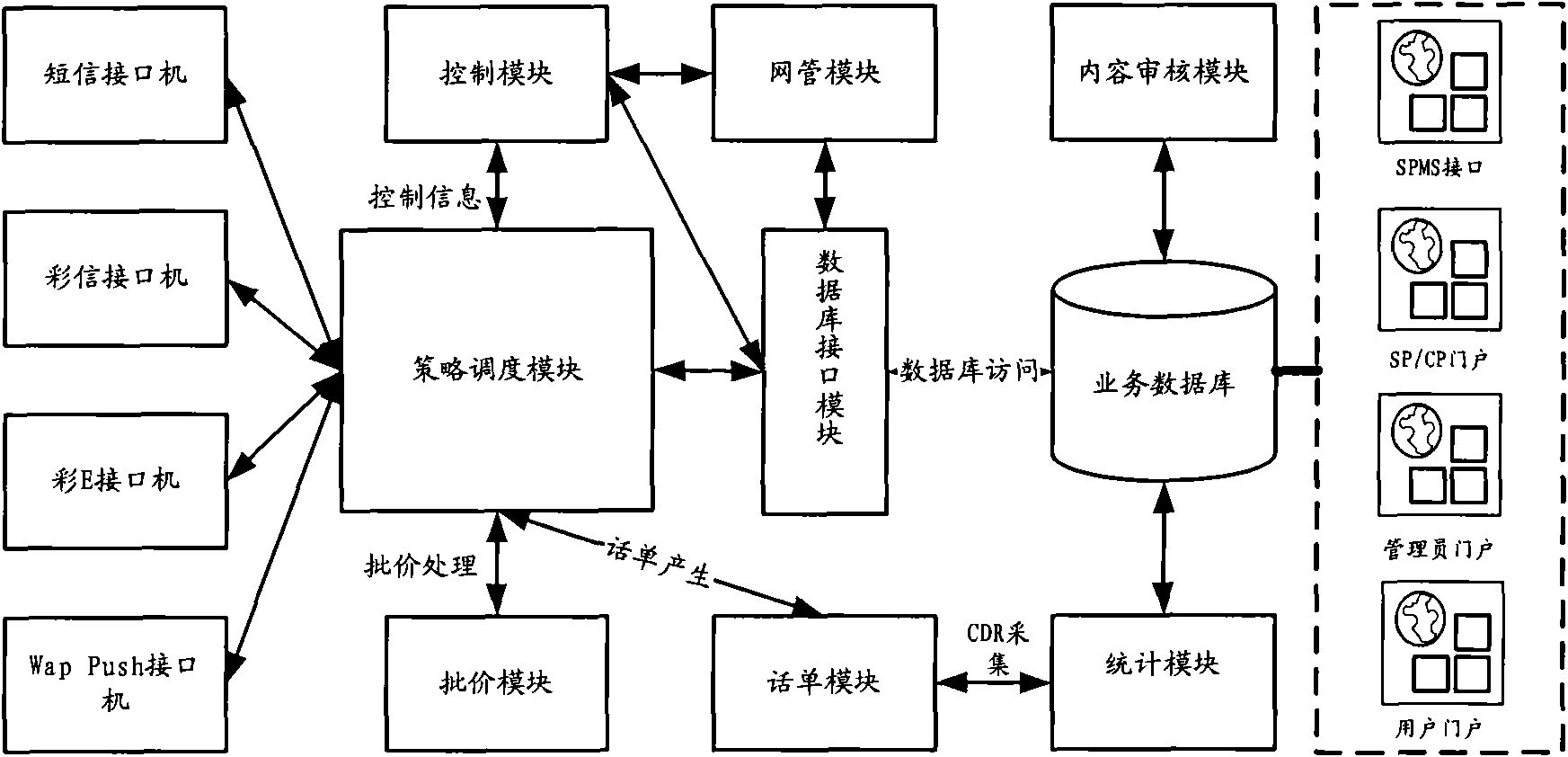

Service container system for SP/CP

InactiveCN101621758AFlexible and fastOvercoming difficult management problemsAccounting/billing servicesMessaging/mailboxes/announcementsQuality of serviceStatistical database

The invention provides a service container system for SP / CP, comprising an access module used for connecting various exterior protocols; a service enabler used for realizing the relationship between service of each SP / CP and users, and enabling each SP / CP to manage own service content by scheduling policy; a service data base used for providing data required by the service container system; a statistical data base used for computing datum that reflects operation situation of the service container system according to an original service usage record generated by each SP / CP; a ticket storing module used for generating an original information ticket; a portal server used for achieving operation and management between the users, system administrators and SP / CP. The service container system provided by the invention effectively manages various service sources, provides uniform access mode for the users, improves quality of service contents, conducts novel business rapidly and flexibly, meets individual requirements and improves service satisfaction.

Owner:ZTE CORP

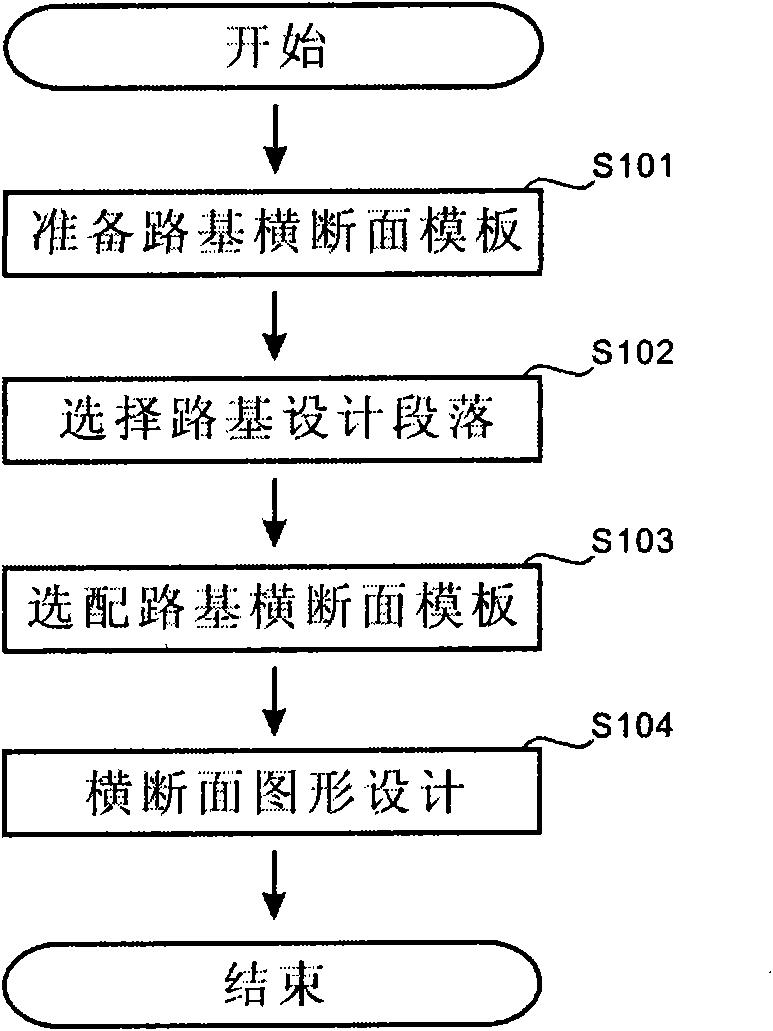

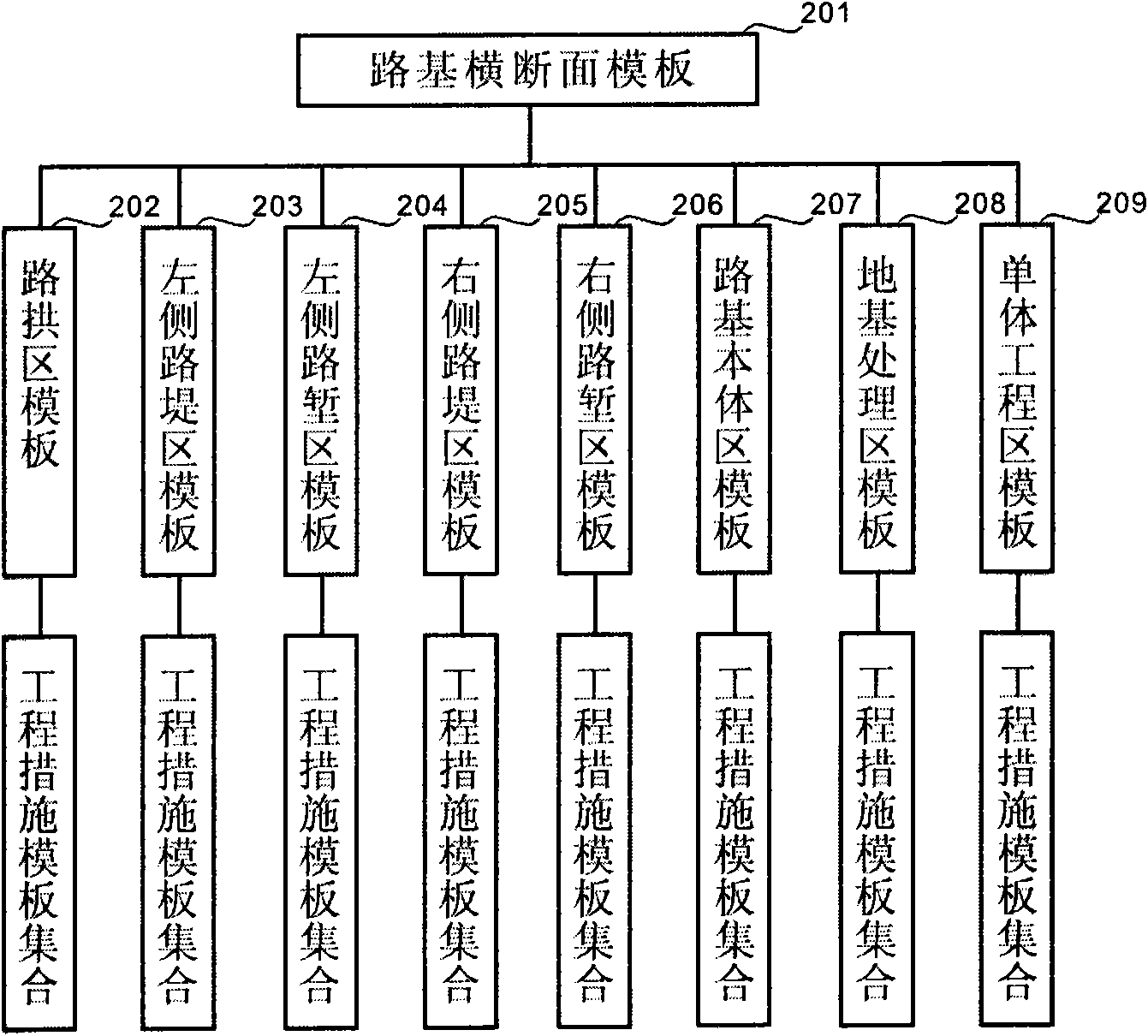

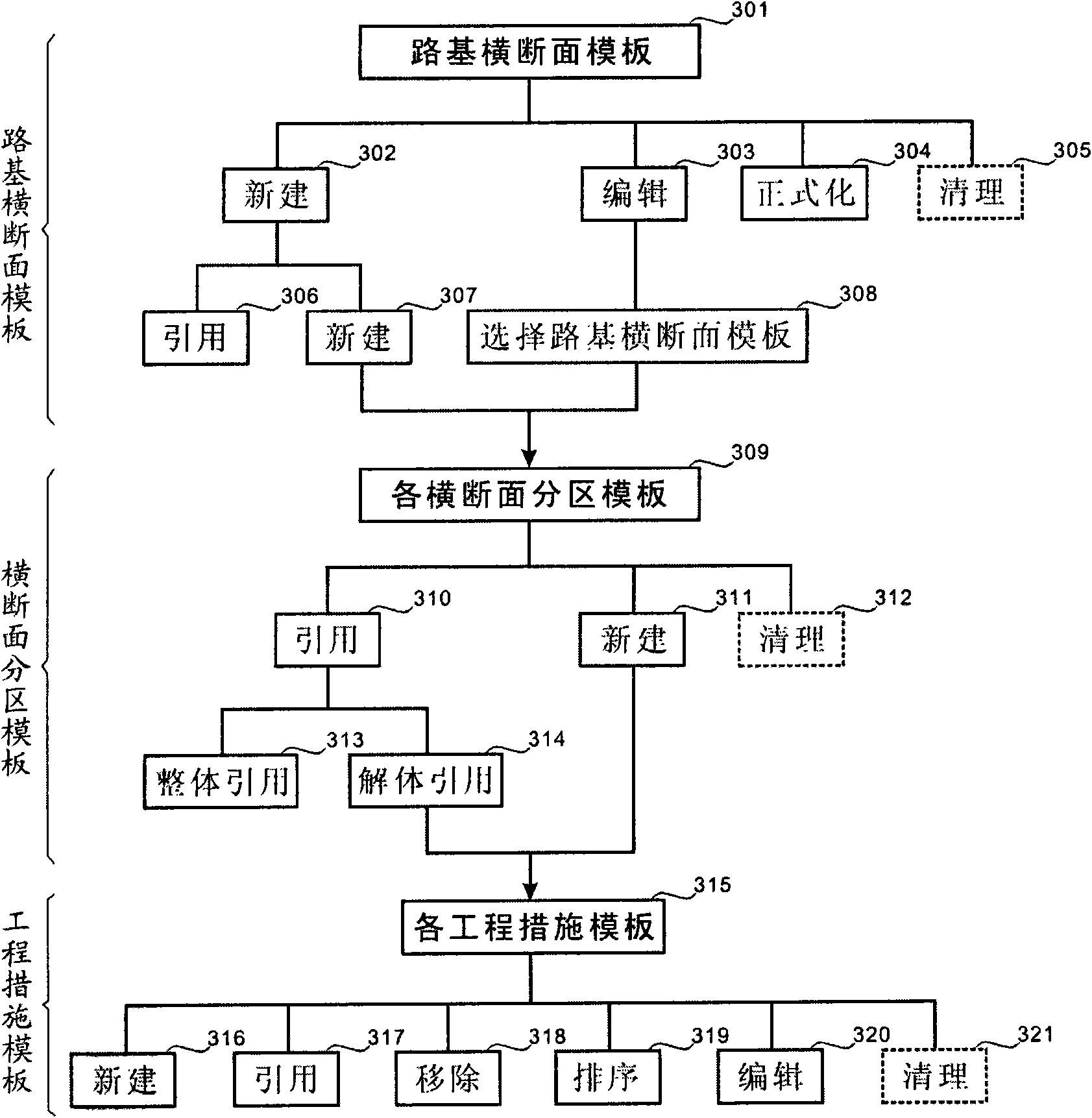

Processing method of subgrade engineering cross section designing template

InactiveCN101866370AEfficient managementEfficient usabilitySpecial data processing applicationsThree levelEngineering

The invention discloses a processing method of a subgrade engineering cross section designing template, comprising the following steps: (A) using the mode of three levels-three classes to build a subgrade engineering cross section designing template system, wherein the phrase of three levels means to divide the template into a subgrade cross section template, a cross section partitioning template and an engineering measure template, and the phrase of three classes means to divide the template at each level into a public template, a private template and a temporary template; (B) managing the subgrade engineering cross section designing template; and (C) using the built subgrade engineering cross section designing template to design a subgrade engineering cross section, and taking the template as a carrier to achieve the purposes of sharing, accumulating and recycling the design experience and the design method.

Owner:SHENYANG RAILWAY SURVEY DESIGN CONSULTING CO LTD

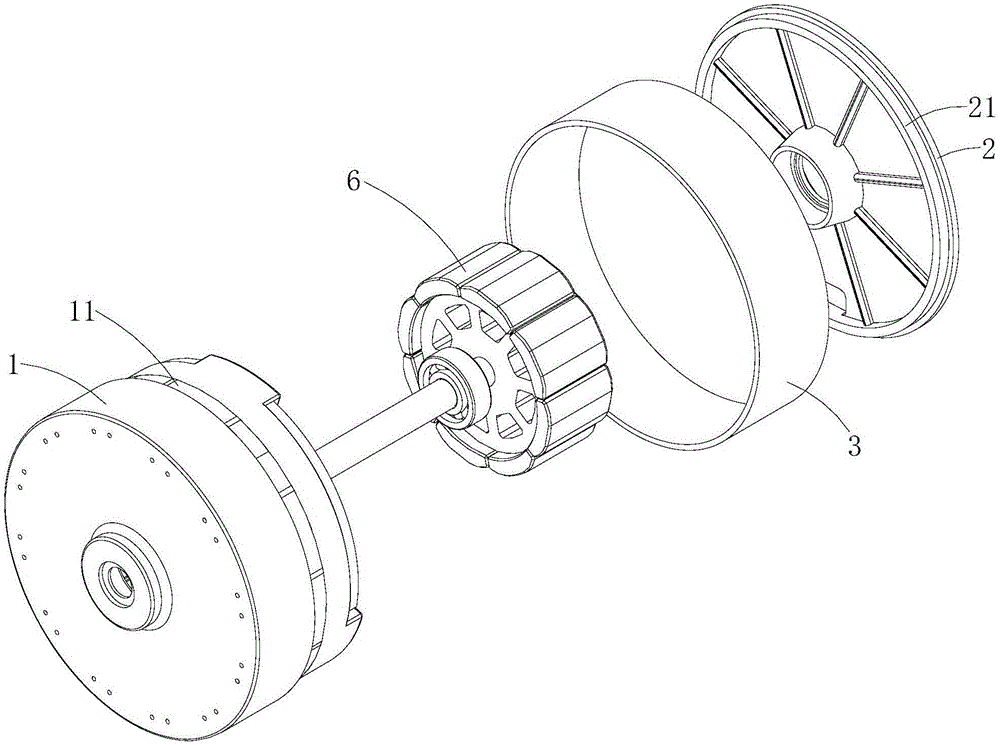

Plastic package motor

InactiveCN105099045AAdaptableShorten the production development cycleSupports/enclosures/casingsEngineeringMechanical engineering

The invention is applicable for the field of a motor, and discloses a plastic package motor. The plastic package motor comprises a plastic package stator assembly, an outer end cover and a metal shell, wherein the outer end cover is arranged at the outer side of the plastic package stator assembly, and the metal shell is connected between the plastic package stator assembly and the outer end cover. The metal shell is arranged between the plastic package stator assembly and the outer end cover, therefore, in the specific application, the plastic package motor can be installed in different application occasions by arranging different installation structures on the metal shell without developing or fabricating a die of the plastic package stator assembly or the outer end cover again, the plastic package motor is compatible with the advantages of high adaptability for an iron shell installation structure, the production and development period of the plastic package motors required by different clients is shortened, the development cost is reduced, the standardardization and market coping abilities of the plastic package motor are enhanced, company cost is favorably saved, and client demand is favorably, rapidly and flexibly coped. Moreover, since the stator part still adopts a plastic package mode, the characteristics of low vibration noise and high reliability inherently possessed by the plastic package motor are still kept.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

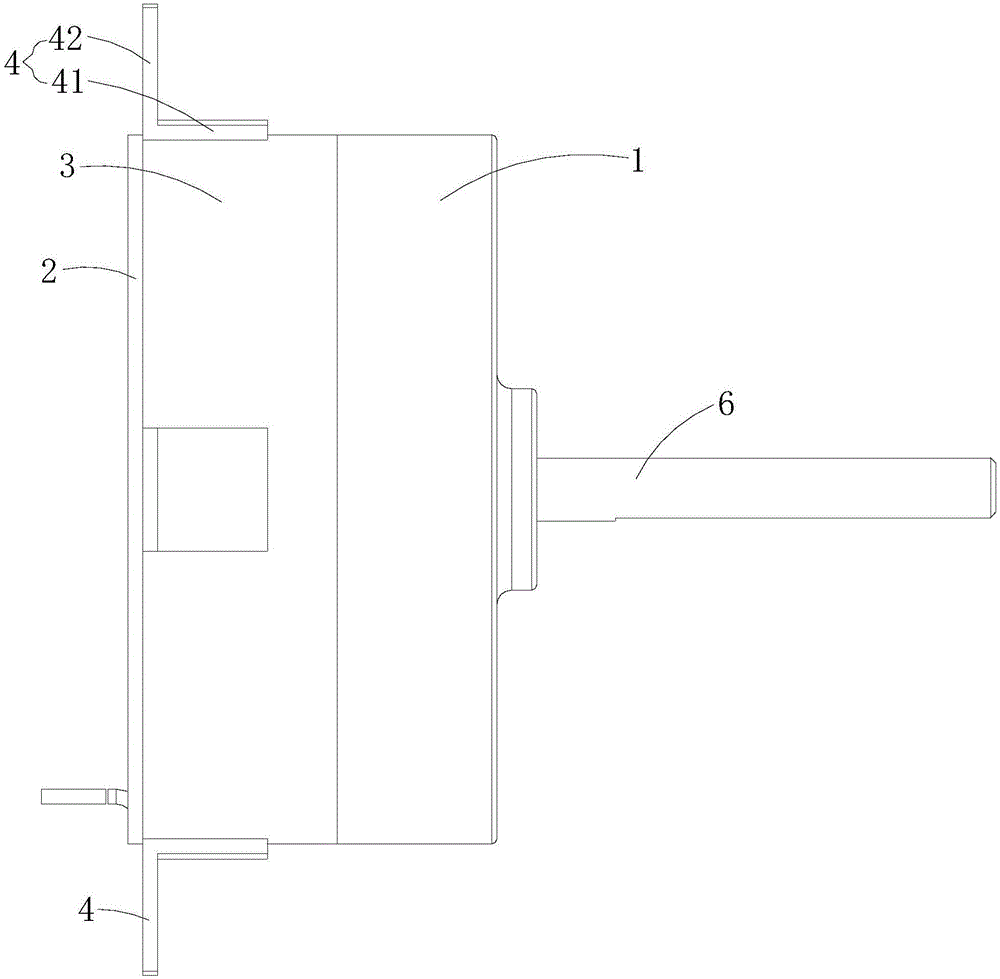

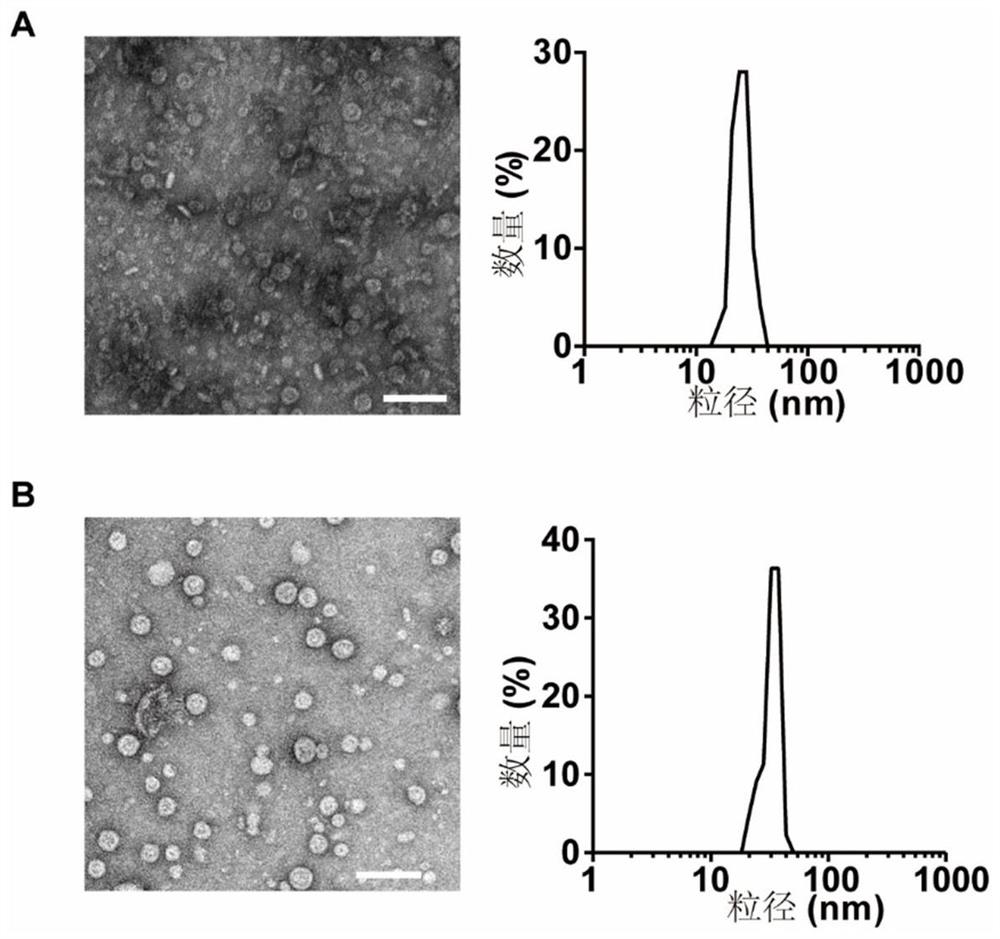

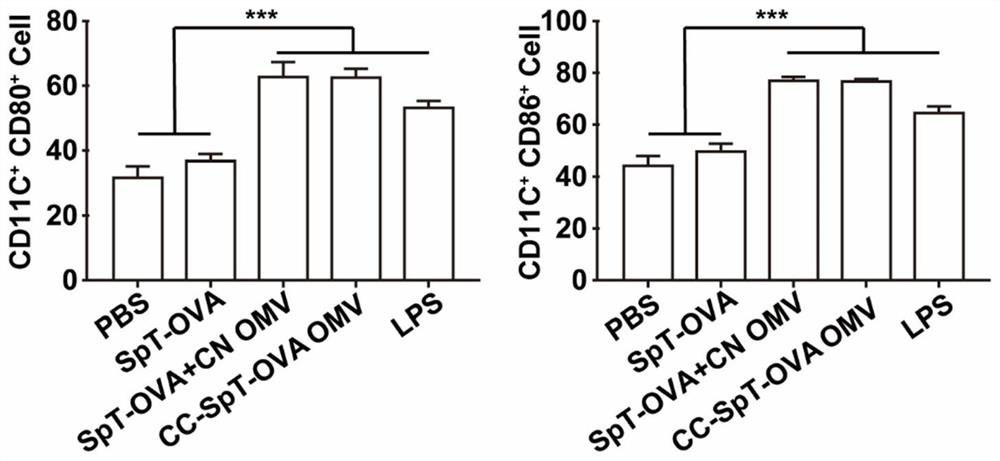

Bacterial outer membrane vesicle, universal nano vaccine containing bacterial outer membrane vesicle as well as preparation method and application thereof

ActiveCN112472802AFlexible and fastGood biocompatibilityNanomedicineCancer antigen ingredientsAntigenImmunity

The invention relates to a bacterial outer membrane vesicle, a nano vaccine containing the bacterial outer membrane vesicle as well as a preparation method and application thereof. The bacterial outermembrane vesicle contains molecular gluewater protein SpyCatcher and / or SnoopCatcher, the tumor vaccine comprises the bacterial outer membrane vesicle and an antigen connected with the bacterial outer membrane vesicle in the form of an isopeptide bond, and the antigen carries SpyTag and / or SnoopTag. According to the invention, the bacterial outer membrane vesicle containing molecular gluewater protein SpyCatcher and SnoopCatcher is used as a tumor vaccine platform and is connected with the antigen carrying SpyTag and / or SnoopTag to obtain the tumor vaccine, and the tumor vaccine can effectively activate an organism to generate innate immunity and realize specific killing of a plurality of antigens at the same time. According to the method, personalized tumor vaccines for tumors from different sources can be rapidly obtained.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

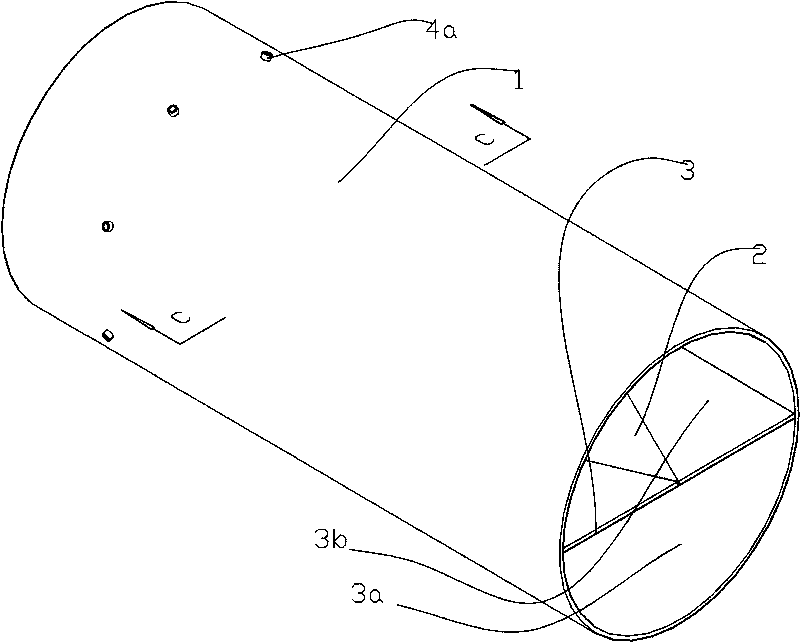

Aircraft

InactiveCN101693469ASimple structureFlexible and fastPower plant typeAircraftsFlight vehicleSubmarine

The invention relates to an aircraft, in particular to a vertical / short take-off and landing aircraft which is characterized in that a high-speed airflow generated when a turbojet engine works blows through airfoils to generate the required lift force when the aircraft takes off, lands and flies. The aircraft can be used as a surface ship or a submarine, and can take-off and land in water. The aircraft can be also designed into a pilotless aircraft, a cruise missile, an underground latent amphibious striking weapon, or various flying vehicles.

Owner:徐林波

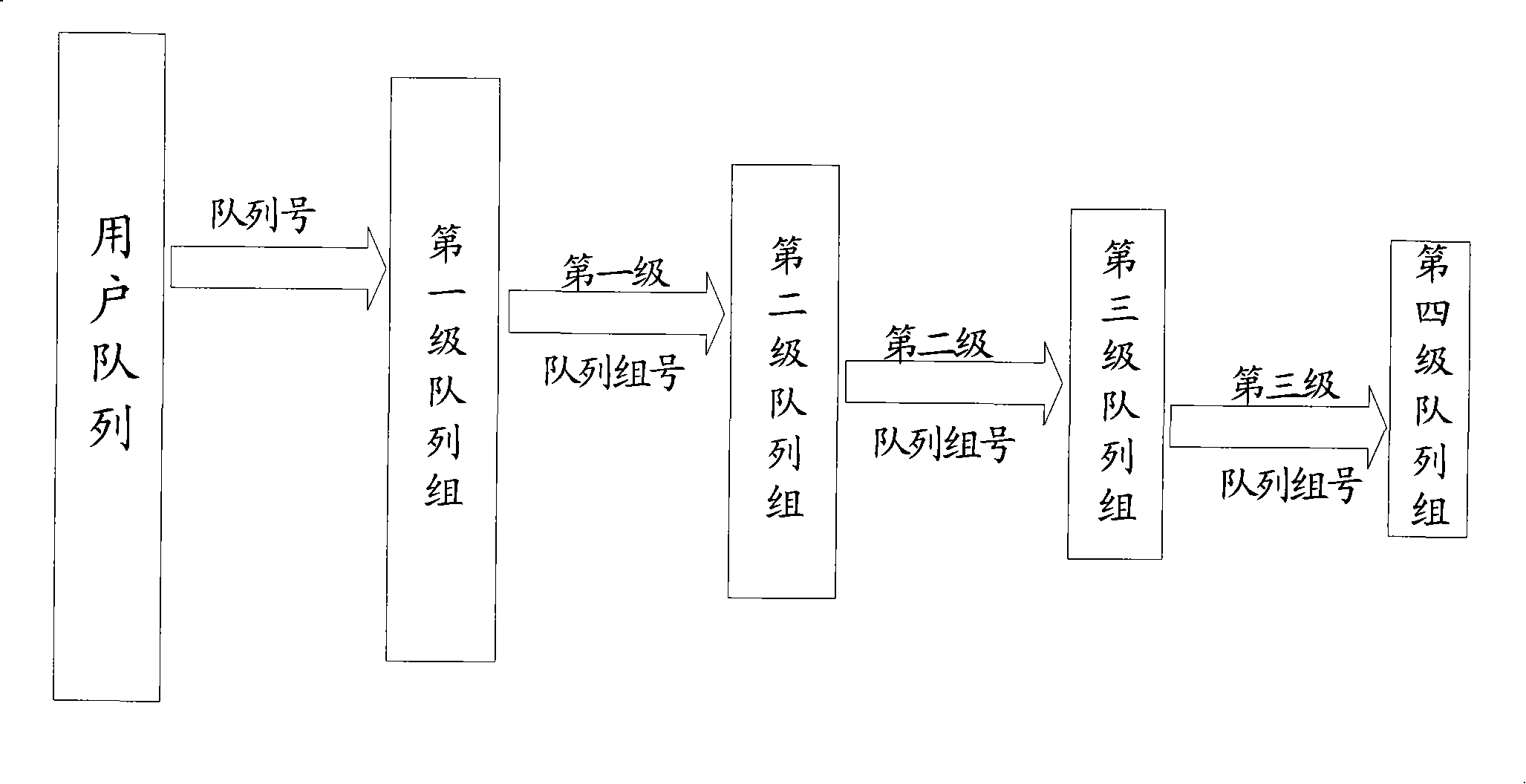

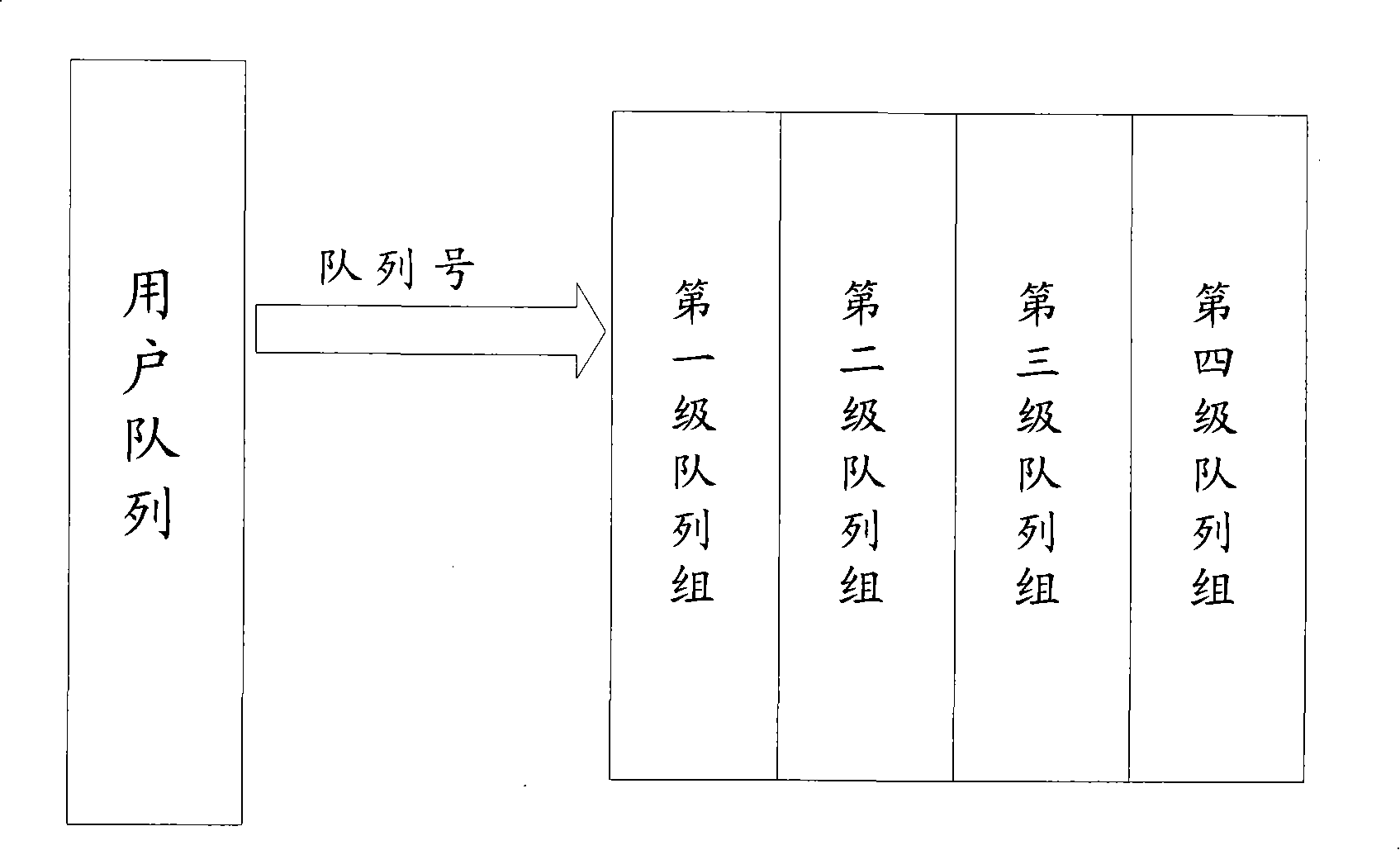

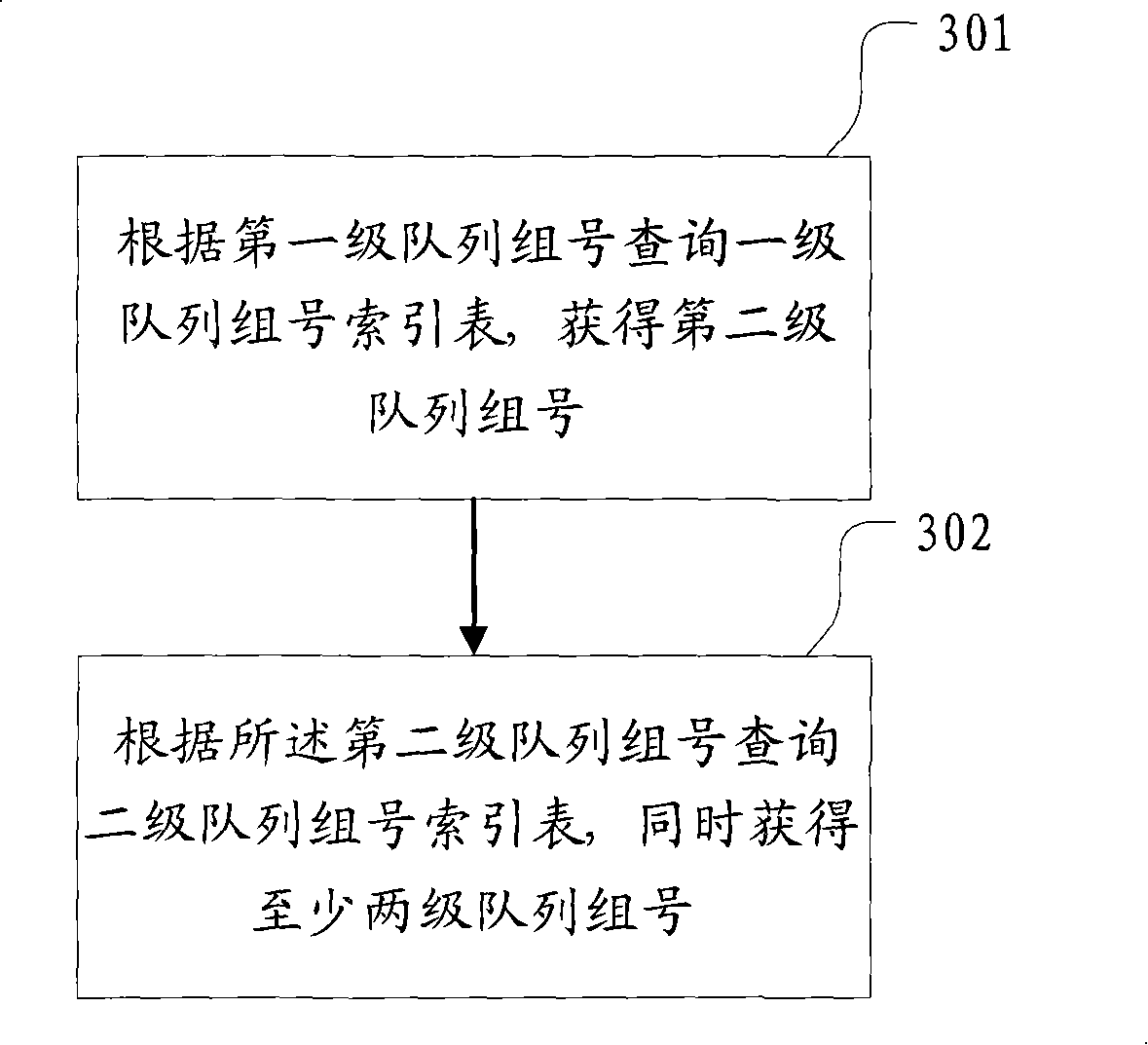

Queue index method, device and traffic shaping method and device

InactiveCN101237417ASave resourcesFlexible and fastData switching networksResource savingDistributed computing

The embodiment of the invention discloses a queue index method and a device thereof, a flow shaping method and a device thereof, which relates to the communication technical field. The invention can achieve the flexible, rapid and resource-saving effects in queue index and flow shaping. The queue index method provided by the embodiment of the invention comprises the following steps that: according to a first-stage queue group number, a first-stage queue group number index table is searched and a second-stage queue group number is acquired simultaneously; the first-stage queue group number index table comprises a second-sage queue group number index table; according to the second-stage queue group number, the second-stage queue group number index table is searched and at least two stage queue group numbers are acquired simultaneously; the second-stage queue group number index table at least comprises a third-stage queue group number index table and a fourth-stage queue group number index table. The embodiment of the invention can be applied to various occasions which need hierarchical scheduling of queue groups.

Owner:HUAWEI TECH CO LTD

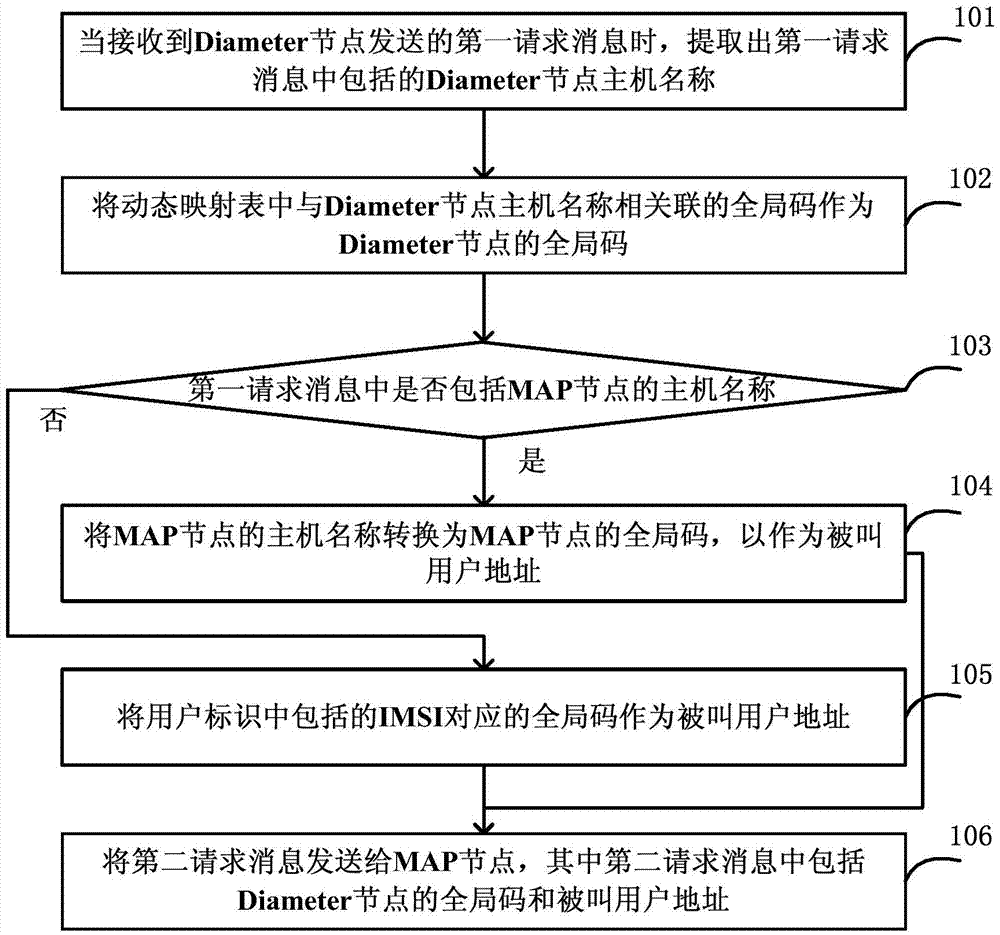

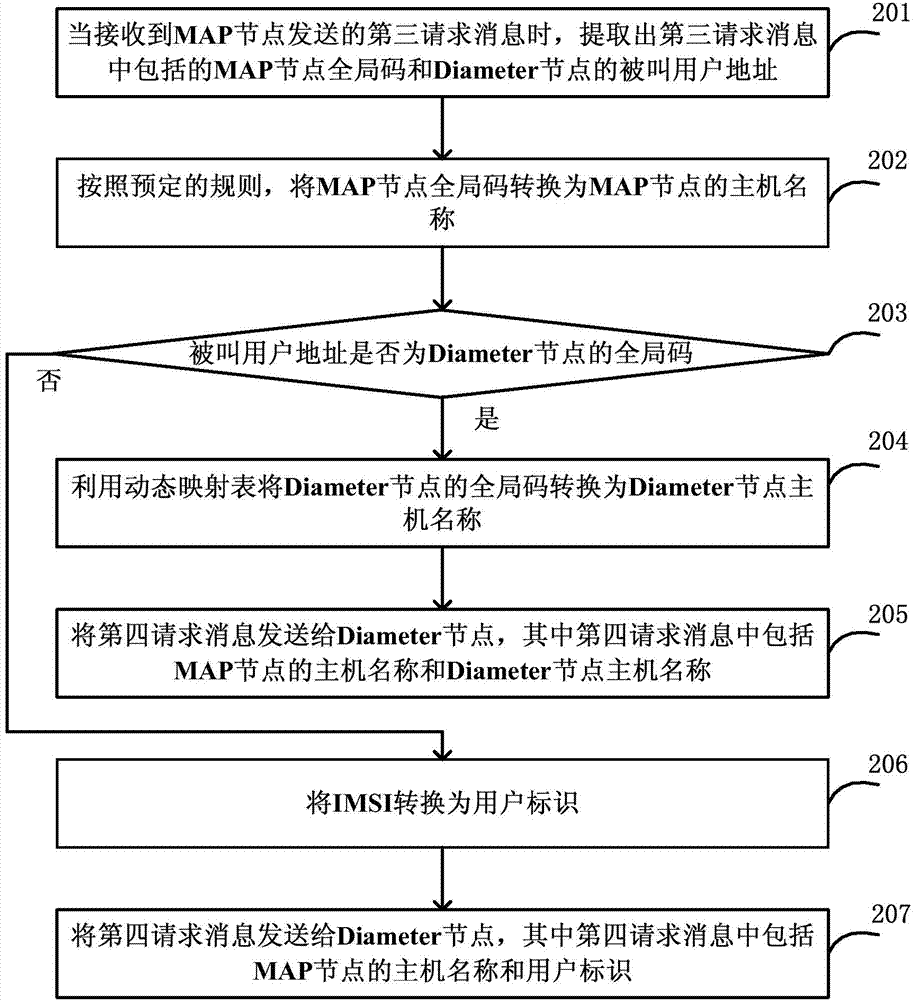

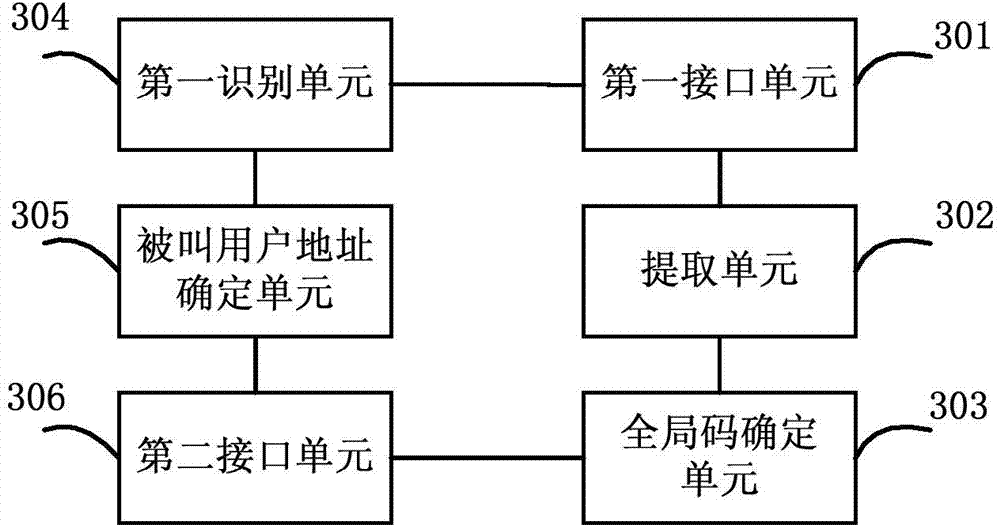

Method and interworking function device for converting routing parameters

ActiveCN104735645AAvoid synchronous coordinationFast and flexibleMachine-to-machine/machine-type communication serviceNetwork data managementThird generationInterconnection

The invention discloses a method and interworking function device for converting routing parameters. The method comprises the steps: when a first request message sent by a Diameter node is received, extracting a Diameter node host name contained in the first request message; using a global title related to the Diameter node host name in a dynamic mapping table as a global title of the Diameter node; judging whether the first request message contains a host name of a MAP node used as a called party or not; if the host name of the MAP node is contained, converting the host name of the MAP node into the global title of the MAP node according to a preset rule, and using the global title as a called user address; if the host name of the MAP node is not contained, using the global title corresponding to an IMSI in user identification as the called user address; sending a second request message to the MAP node, wherein the second request message comprises the global title and the called user address of the Diameter node. Routing parameter conversion is performed between a Diameter protocol and a MAP protocol through the IWF, and interconnection and interworking of different protocols between LTE and a 2G / 3G network are ensured.

Owner:CHINA TELECOM CORP LTD

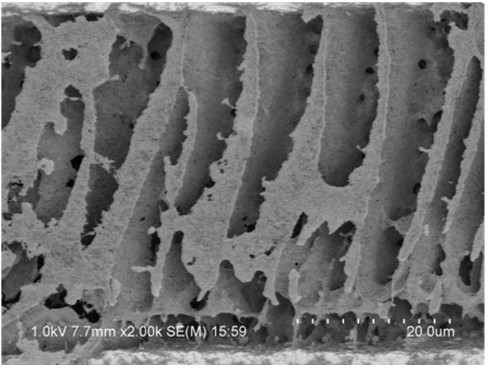

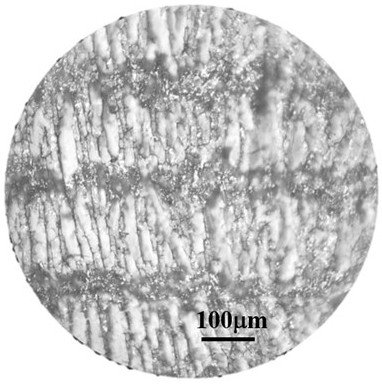

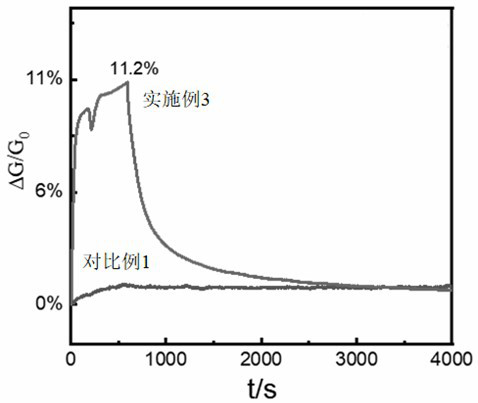

Interdigital electrode material with vertical orientation three-dimensional structure and preparation method and application thereof

ActiveCN113155914AWide variety of sourcesComposite state can be adjustedGeneral water supply conservationMaterial resistanceNanowireFreeze-drying

The invention discloses an interdigital electrode material with a vertical orientation three-dimensional structure and a preparation method and application thereof. The interdigital electrode material with the vertical orientation three-dimensional structure is formed by arranging nanosheet layer structures between interdigitals of an interdigital electrode at intervals in a near-vertical orientation mode, wherein the nanosheet layer structures are formed by stacking nanometer materials. The form of the nanometer material is one or more of zero-dimensional quantum dots, nanometer particles, one-dimensional nanometer tubes, nanometer rods, nanometer wires or two-dimensional nanometer sheet layers. The preparation method comprises the following steps: coating a nano material dispersion liquid in a groove of an interdigital electrode, freezing, and then freeze-drying, thereby obtaining the electrode. The interdigital electrode material with the vertical orientation three-dimensional structure is applied to a sensor. The interdigital electrode material with the vertical orientation three-dimensional structure is wide in raw material source, the thickness of a nanometer material is as low as 6 microns, the composite state of the nanometer material can be regulated and controlled, and the gas sensing response degree is remarkably improved. The method is simple in process, low in cost and suitable for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

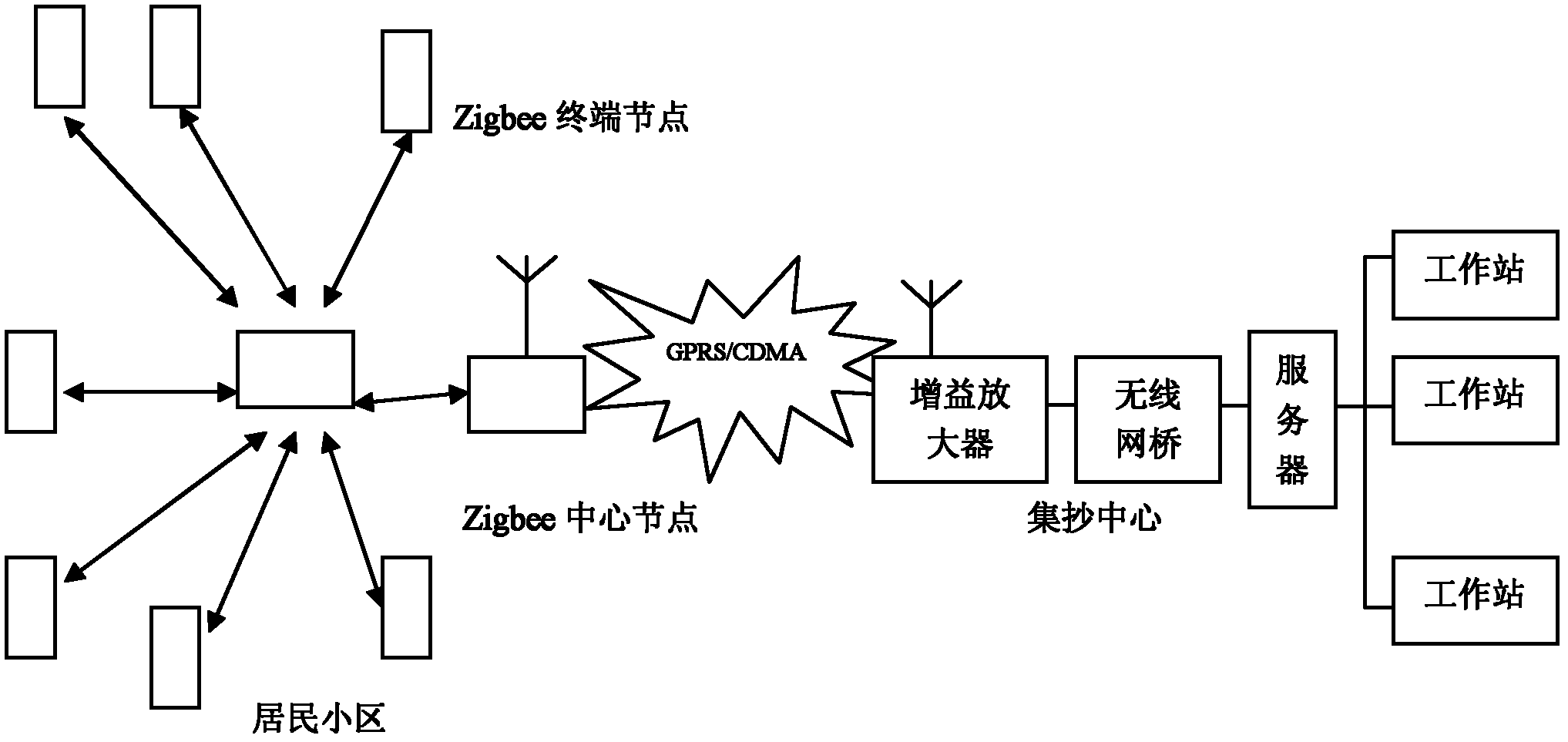

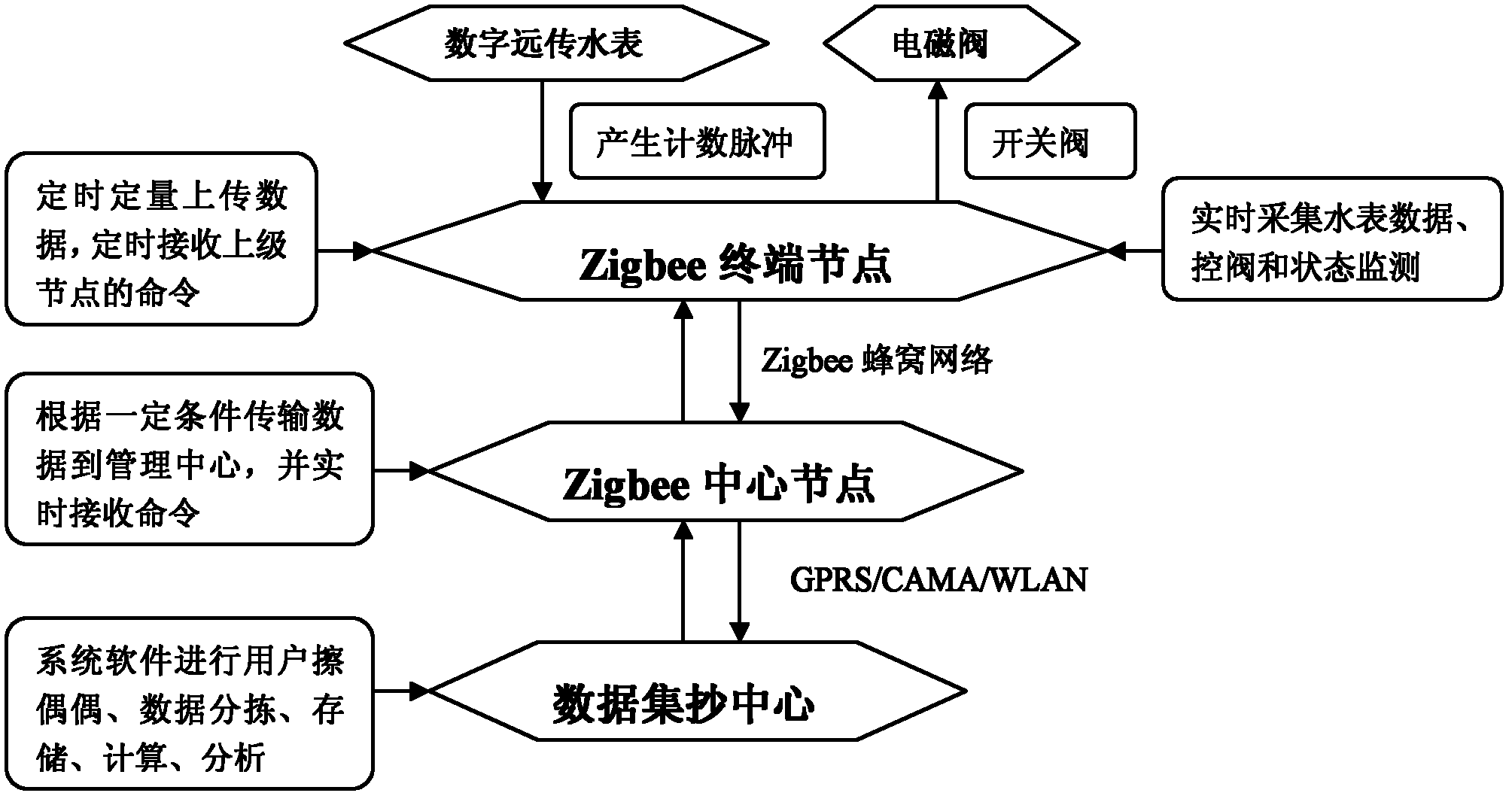

Wireless automatic meter reading system for community

InactiveCN103106782AReliable communicationFast and flexibleTransmission systemsNetwork topologiesTelecommunicationsData set

The invention discloses a wireless automatic meter reading system for a community. The wireless automatic meter reading system comprises a plurality of Zigbee central nodes, a plurality of Zigbee terminal nodes and a data centralized reading center, wherein a plurality of Zigbee terminal nodes are arranged in apartment buildings in the community, serve as signal input ends of the wireless automatic meter reading system for the community, and are used for acquiring data of meters to be read; signal output ends of the Zigbee terminal nodes are wirelessly connected with the corresponding Zigbee central nodes; and the Zigbee central nodes are wirelessly connected with the data centralized reading center through a network. The invention provides an intact space limitation-free wireless remote automatic meter reading network which is stable and reliable in communication, quick and flexible.

Owner:WUXI NANLIGONG TECH DEV

Silicone reaction device

InactiveCN107930478AStir wellIncrease contact areaRotary stirring mixersTransportation and packagingEngineering

The invention discloses a silicone reaction device which comprises a reaction tank, wherein a feed pipe is connected into a through hole formed in one side of the top of the reaction tank in a sleeving manner; a discharging sleeve is connected to the bottom of the reaction tank in a sleeving manner; a discharge valve is arranged on the discharging sleeve; a motor is fixedly connected to the top ofthe reaction tank; and the output end of the motor is fixedly connected with the top end of a rotating rod. Due to matched use of the motor, a first bevel gear, a second bevel gear, a movable rod, afirst gear, a second gear and a chain, the first stirring rod and the second stirring rod are symmetrically distributed by taking a main rod as an axis, so that silicone mixtures can be fully stirred.Since the first stirring rod and the second stirring rod rotate in a vertical direction, the contact area of the first stirring rod and the second stirring rod and a silicone mixed solution is further enlarged, phenomena of aggregation and caking can be avoided, and the stirring quality is improved. Therefore, the silicone mixed solution can be uniformly stirred.

Owner:WUXI HITXINCHENG POLYMER TECH

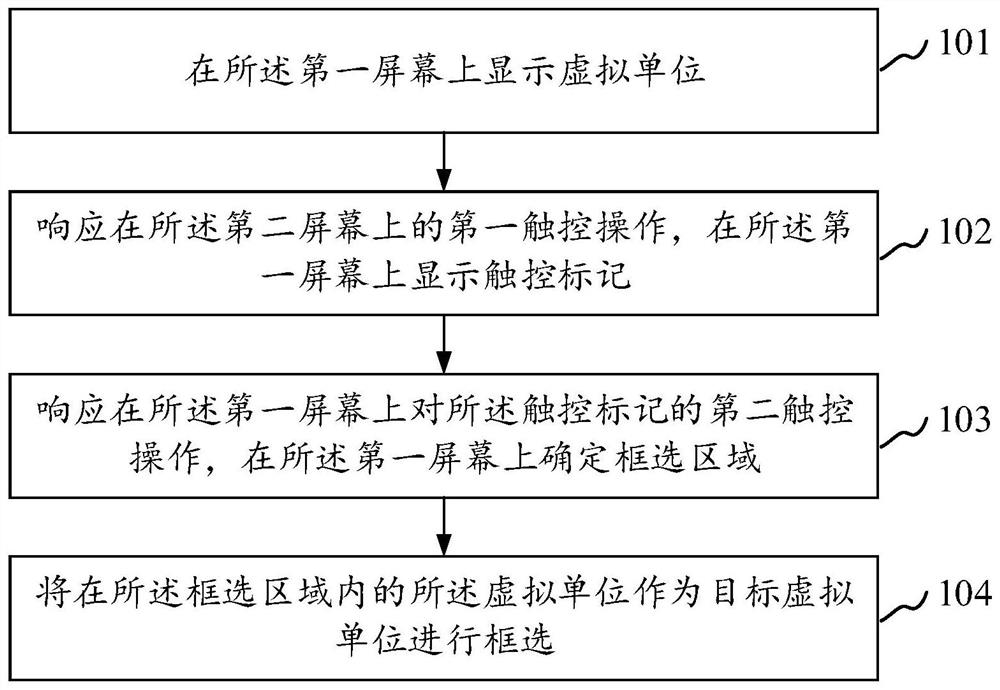

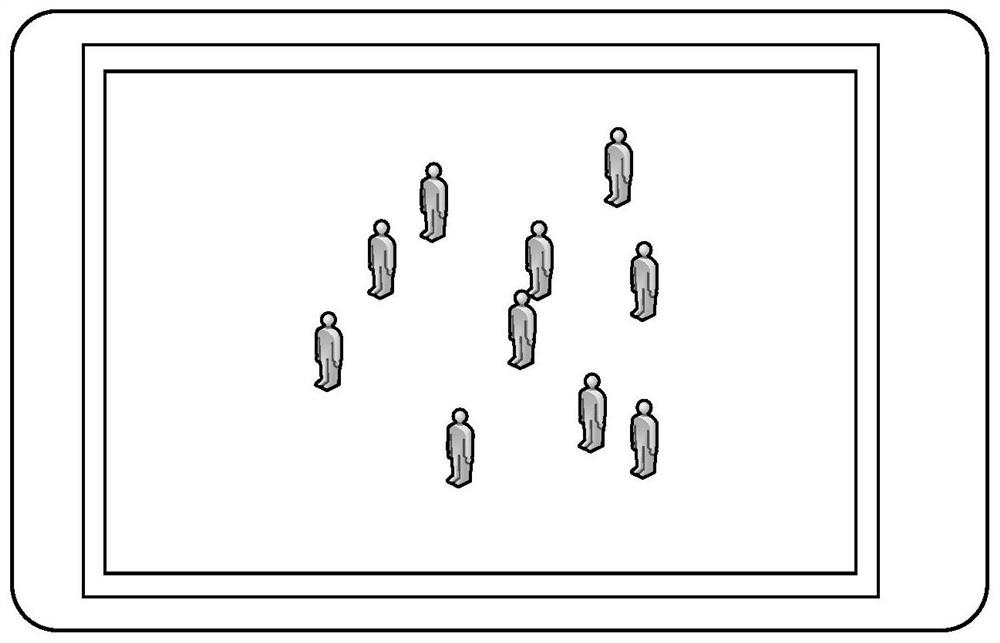

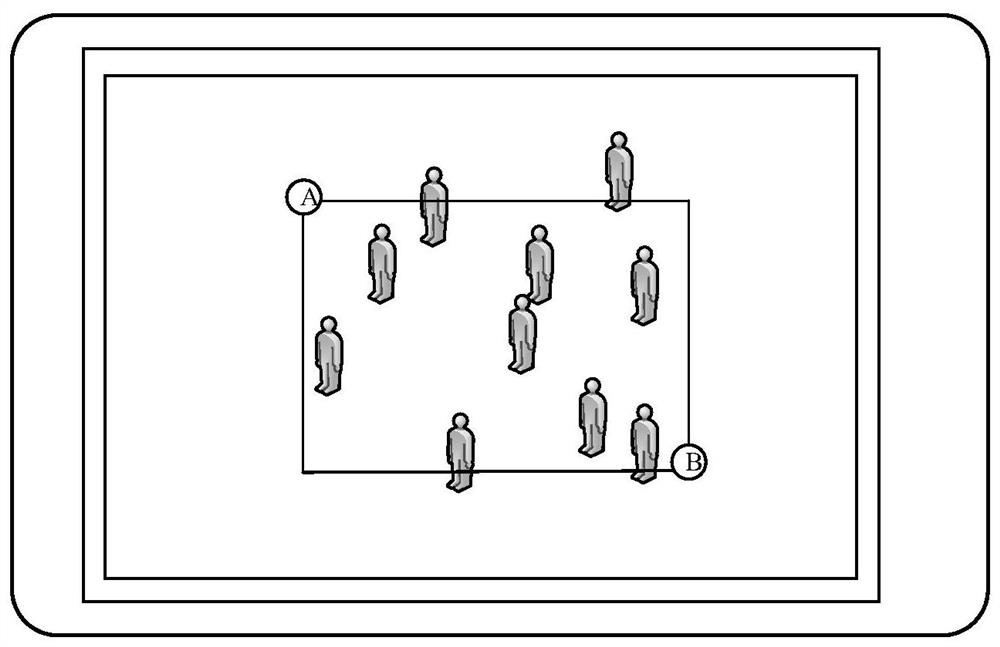

Terminal operation method and device, electronic equipment and storage medium

PendingCN113680047AFast and flexibleMeet immediacy requirementsVideo gamesInput/output processes for data processingEmbedded systemElectronic equipment

Embodiments of the invention provide a terminal operation method and device, electronic equipment and a storage medium. The method is applied to terminal equipment with a first screen and a second screen. The method comprises the following steps: displaying a virtual unit on a first screen; in response to a first touch operation on a second screen, displaying a touch mark on the first screen; in response to a second touch operation on the touch mark on the first screen, determining a frame selection area on the first screen; and carrying out frame selection by taking the virtual unit in the frame selection area as a target virtual unit. In the embodiments of the invention, the touch operation is performed on the first screen and the second screen of the terminal equipment, the frame selection of the virtual unit is quickly and flexibly completed, and a requirement on instantaneity is met because the frame selection does not need to be triggered by pressing the screen for a long time or double clicking the screen for triggering the frame selection.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

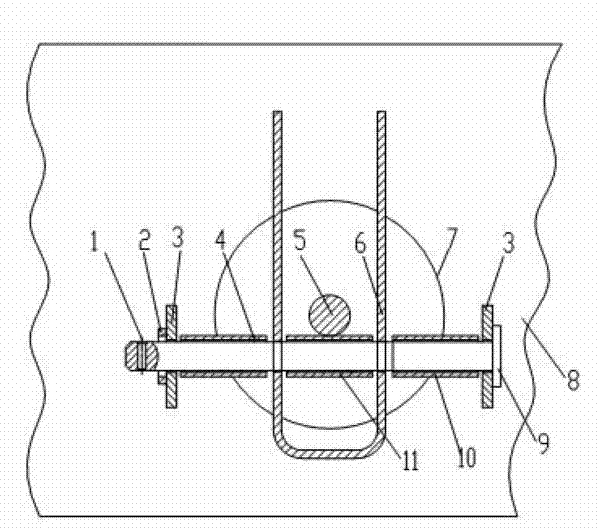

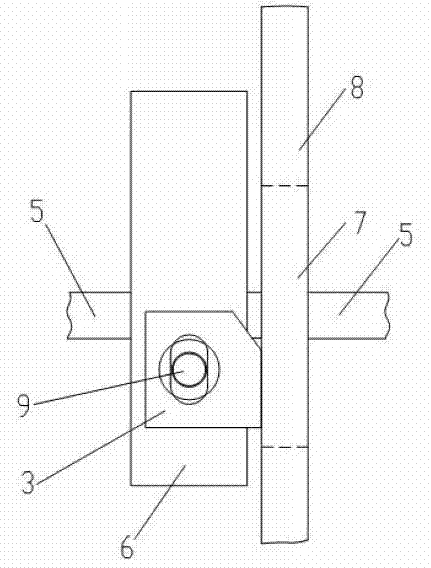

Wagon brake pull rod limiting carrier

The invention discloses a wagon brake pull rod limiting carrier. The wagon brake pull rod limiting carrier comprises a cross beam web, carrying plates, a T-shaped pin and a brake pull rod. The upper end of the cross beam web is perpendicularly connected with the lower face of a bottom plate of a railway vehicle. A through hole is formed in the middle of the cross beam web. The carrying plates are connected to the cross beam web on the left side and the right side of the through hole. Holes are formed in the carrying plates, the T-shaped pin penetrates the holes of the carrying plates, and the brake pull rod is positioned on the T-shaped pin and penetrates the through hole. The wagon brake pull rod limiting carrier is characterized in that the limiting carrier is further provided with a U-shaped retaining plate, an opening of the U-shaped retaining plate faces upwards and holes are formed in two side walls of the U-shaped retaining plate, the T-shaped pin penetrates the holes of the carrying plates and the holes of the U-shaped retaining plate, a first sleeve is sleeved on the T-shaped pin inside the U-shaped retaining plate, a second sleeve and a third sleeve are sleeved on the T-shaped pin on two sides of the U-shaped retaining plate respectively, and the brake pull rod is positioned on the first sleeve inside the U-shaped retaining plate. By the U-shaped retaining plate, the brake pull rod can be prevented from deviating leftwards and rightwards and is enabled to reset successfully.

Owner:CRRC SHIJIAZHUANG CO LTD

Wood sculpture wood chip removing and collecting device

InactiveCN111421987AEasy to clear collectionIncrease flexibilityHand artistic toolsDirt cleaningMechanical engineeringPulp and paper industry

The invention discloses a wood sculpture wood chip removing and collecting device. The wood sculpture wood chip removing and collecting device structurally comprises a fan cover chip removing wheel cap, a bundling and pressing cylinder, a lifting handle, a supporting frame sleeve, a collecting groove cylinder, a rubber sleeve and a wire. According to the wood sculpture wood chip removing and collecting device, the fan cover chip removing wheel cap is matched with the bundling and pressing cylinder, so that the air draft effect of a sliding cavity of a thin frame ring and a shutter fin plate isformed; and a sliding frame cushion block and a suction swing frame body are used for alternately scraping and cutting a curled wood chip strip, so that a reinforcing rib thin rod is matched with thesuction swing frame body to form an interactive dynamic and static combined scraping and brushing effect, the linkage of an overall mechanical rod piece and the effect of sucking and inserting the bundling and pressing cylinder into the air wall are improved, wood chips after wood sculpture can be guided into the collecting groove cylinder in a cover cap absorption effect, the drying effect of centralized collection of the wood chips is improved, the situation that the dead weight of the waste chips is interfered by water washing dry and wet mixing is avoided, the pretreatment effect of the broken chips is also improved, the compactness of the wood chip compaction in the later period is guaranteed, the block is light and convenient to carry and treat, the overall wood chip removing and collecting effect is improved, and the rapid flexibility of the wood sculpture after being improved is guaranteed.

Owner:张育南

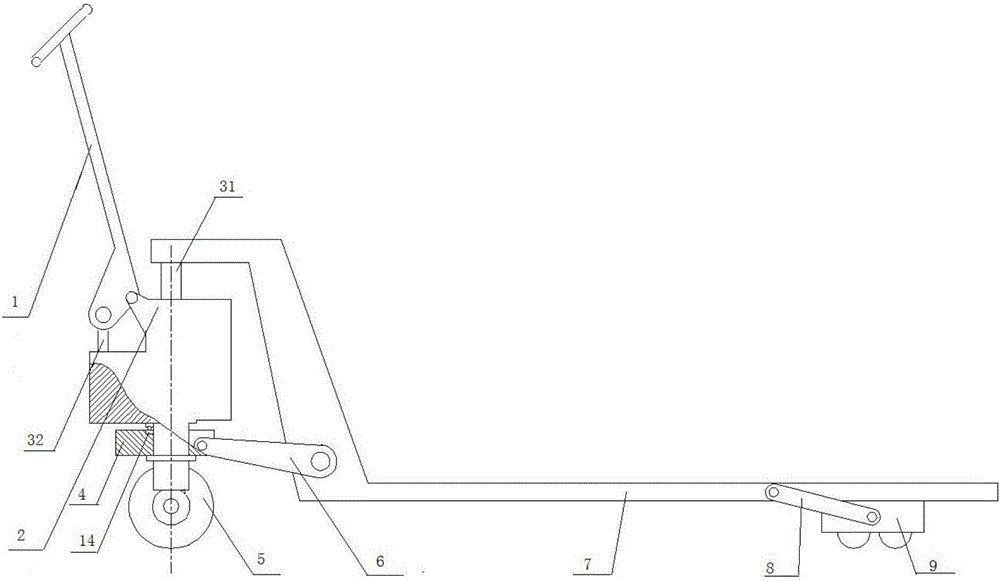

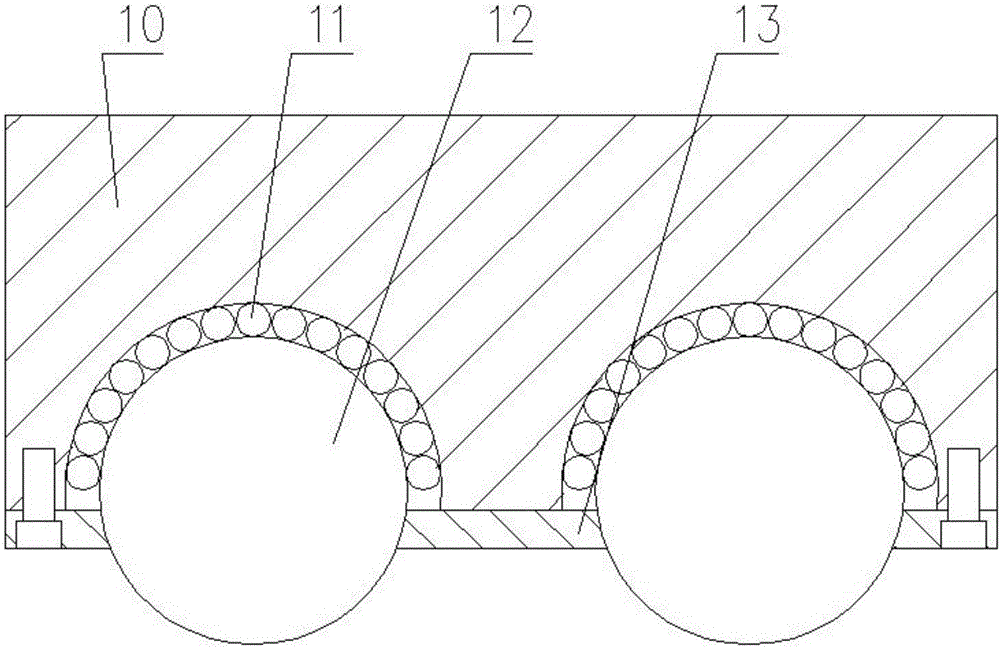

Manual hydraulic carrying vehicle

InactiveCN105905154AFlexible and fastImprove transport efficiencyHand leversLifting devicesGround contactDrive wheel

The invention discloses a manual hydraulic carrying vehicle. The manual hydraulic carrying vehicle comprises a handle, an oil cylinder body, a large piston rod, a small piston rod, a supporting base body, a rear wheel, a rear connection rod, a vehicle body, a front connection rod and a front support. The front support comprises a support body, balls, rolling balls and a gland. The support body is provided with spherical-surface grooves. The rolling balls are put in the spherical-surface grooves. The multiple balls are put between each spherical-surface groove and the corresponding roll ball. Round holes are formed in the positions, corresponding to the rolling balls, of the gland. The gland is connected with the support body through screws. The balls and the rolling balls are limited in the spherical-surface grooves, and a part of the rolling balls makes contact with the ground through the gland. According to the manual hydraulic carrying vehicle, the vehicle running direction can be freely changed along with the driving force direction through the novel driving wheel structure, the output of tractive effort of a consignment person during vehicle steering is reduced, the time and effort are saved, and the operation strength is reduced.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO

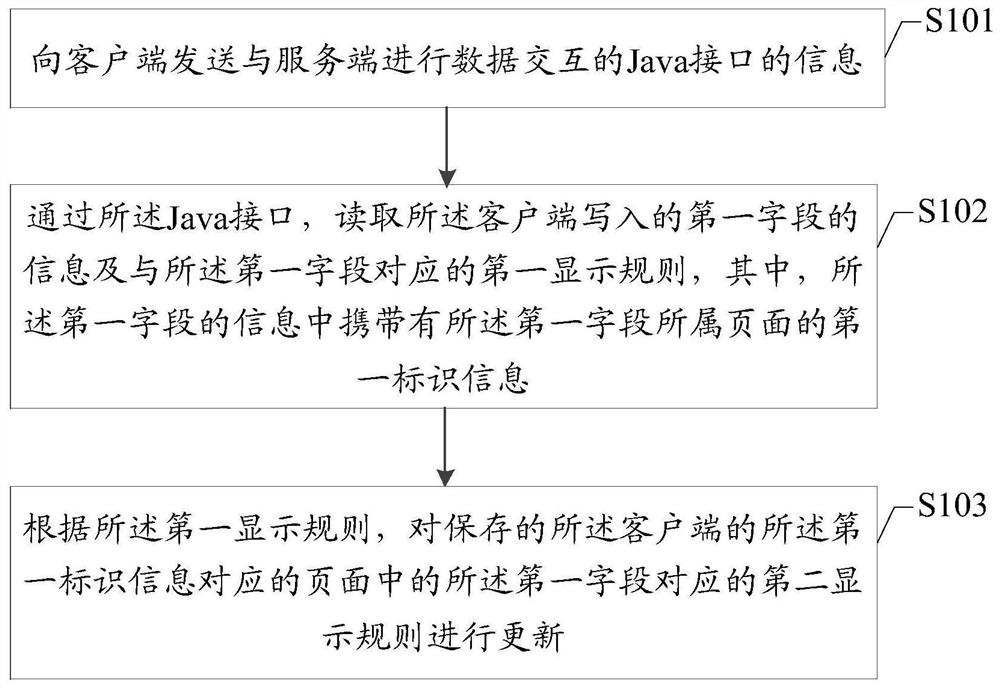

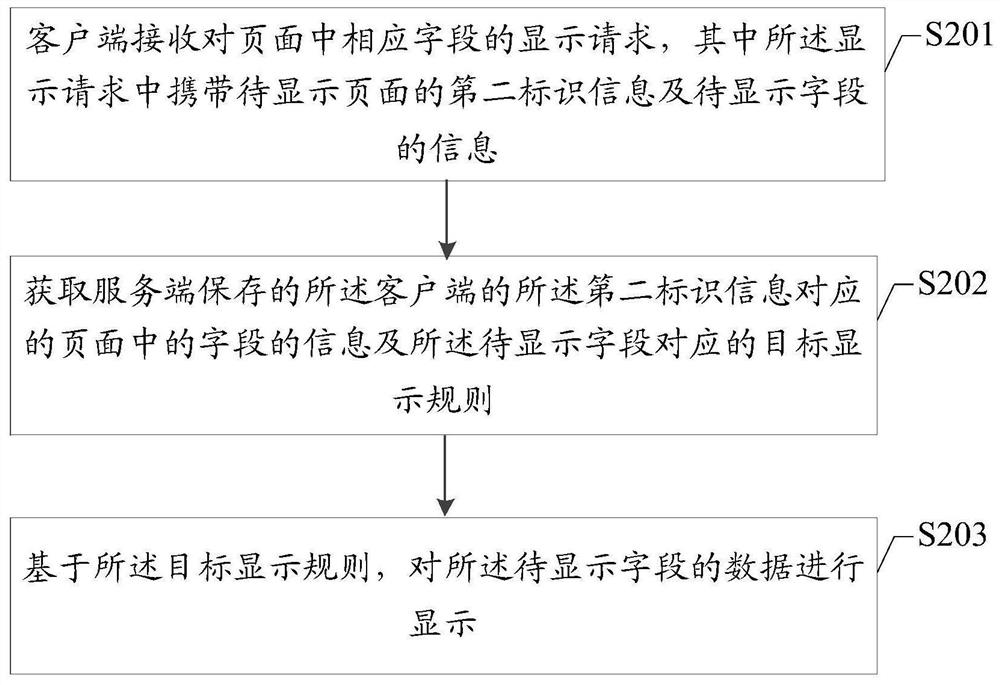

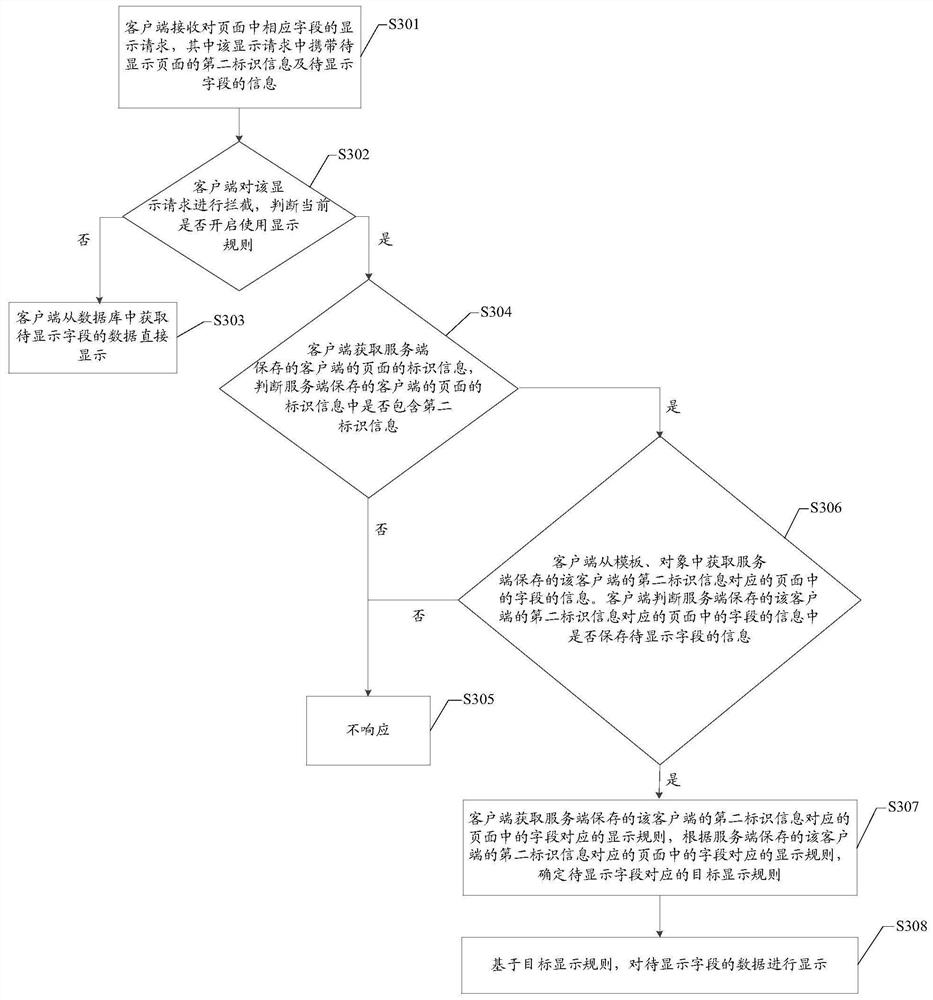

Data display rule determination method and device, data display method and device, equipment and medium

PendingCN113094048AFast and flexibleFlexible and fastExecution for user interfacesSoftware reuseComputer hardwareData display

The invention discloses a data display rule determination method and device, a data display method and device, data display equipment and a medium, which are used for rapidly and flexibly determining a display rule corresponding to a field in a page of a client. According to the method, a server side can read information of a first field written by a client side and a first display rule corresponding to the first field through a Java interface, and the information of the first field carries first identification information of a page to which the first field belongs; and according to the first display rule, the second display rule corresponding to the first field in the page corresponding to the stored first identification information of the client is updated. Through the Java interface, the read first display rule corresponding to the first field written by the client can be a display rule configured by a user for the client in a personalized manner, and cannot be limited by business scenes and the like, so that the display rule corresponding to the field in the page of the client can be quickly and flexibly determined.

Owner:HISENSE GRP HLDG CO LTD

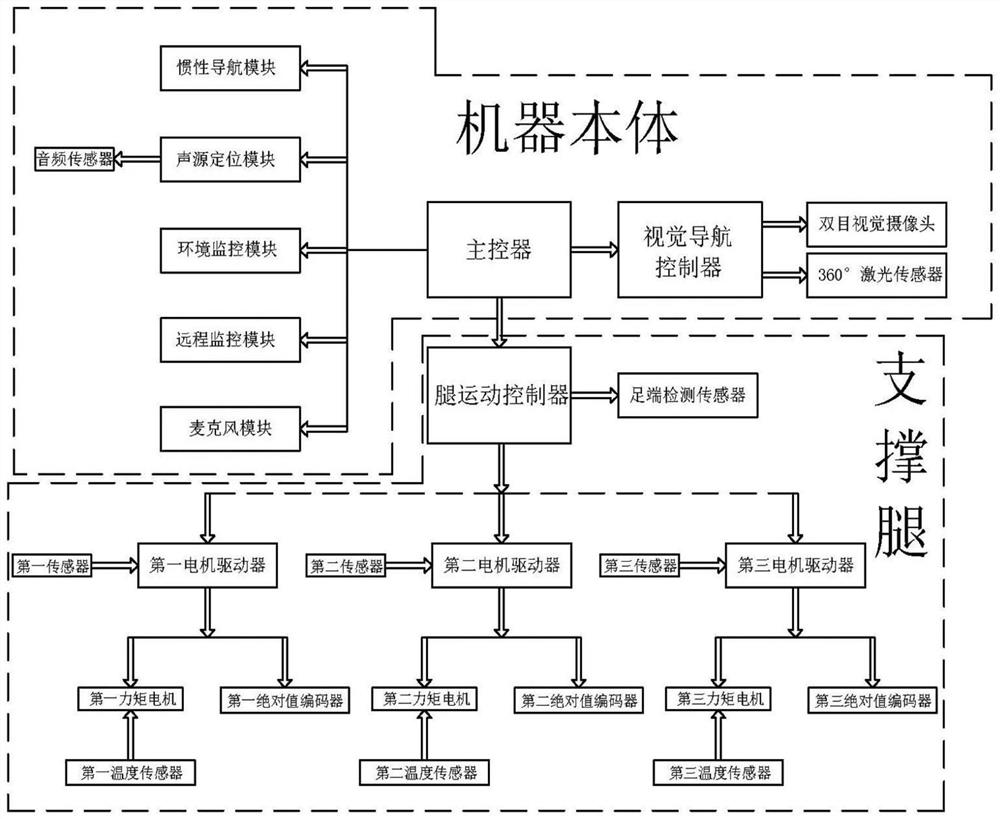

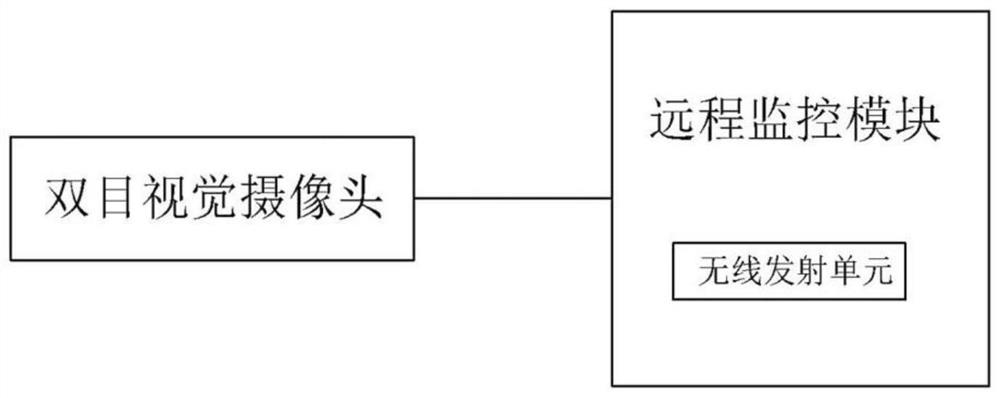

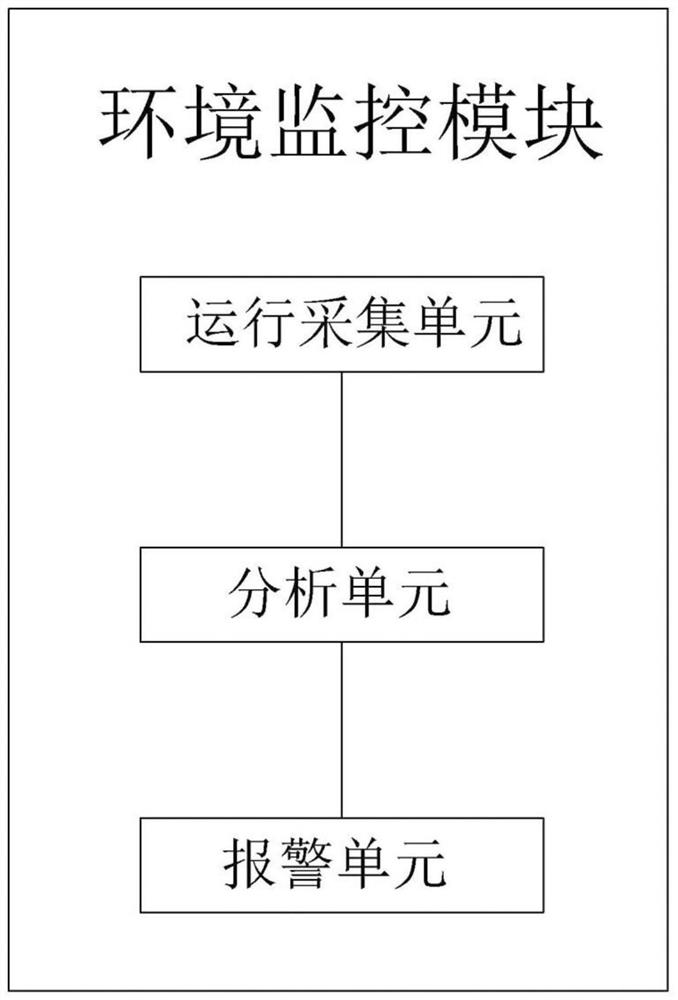

Quadruped robot based on bus

The invention relates to the technical field of robots and particularly relates to a quadruped robot based on a bus. The robot comprises a robot body and four supporting legs arranged on the robot body, wherein a main controller and a lithium battery which are connected with each other are installed in the machine body, the main controller is connected with an EtherCAT bus, and leg motion controllers electrically connected with the EtherCAT bus are arranged on the supporting legs; hip joints, thigh joints and shank joints of the supporting legs are provided with hip joint control mechanisms used for controlling the hip joints to move, thigh joint control mechanisms used for controlling the thigh joints to move and shank joint control mechanisms used for controlling the shank joints to move respectively. The robot is advantaged in that the leg movement controllers are controlled to work through the main controller, then movement of the hip joints, the thigh joints and the shank joints of the supporting legs is controlled, meanwhile, the movement is controlled by the main controller through the EtherCAT bus, and all the movements are fast and flexible.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Surface polishing machining equipment

InactiveCN108747736AQuick sandingFlexible and fastBelt grinding machinesElectric machineryEngineering

The invention discloses surface polishing machining equipment. The surface polishing machining equipment comprises a polishing machine body provided with a support shaft assembly. The support shaft assembly comprises bearing sets. Each bearing set comprises support shaft bearings. A convolution space is arranged between the two bearing sets. A polishing assembly is arranged on the rear side of thesupport shaft assembly and comprises a polishing base frame provided with two abrasive belt wheels, wherein an abrasive belt is in winding connection to the two abrasive belt wheels, and the polishing base frame can drive the abrasive belt to swing up and down around a work rotation shaft. During usage, a rotor is placed on the support shaft assembly, a rotor core is arranged in the convolution space, a drive motor is started, the abrasive belt rotates, then, the polishing base frame is made to swing downwards, and the abrasive belt conducts polishing and grinding on the rotor core. The abrasive belt is soft so that large-area, rapid and soft grinding can be well conducted; and the rotor can be driven to rotate through rotation of the abrasive belt, and accordingly uniform grinding is conducted on the peripheral face of the rotor core. The surface polishing machining equipment is used for motor shaft machining.

Owner:FOSHAN CITY NANHAI POPULA FAN

Variable stiffness filler baggage device and gripper prepared by same

The invention discloses a variable stiffness filler baggage device which comprises an air bag, a cylindrical substrate and an air core. The air bag sleeves the top end of the substrate and is filled with particles, and the air core is connected at the bottom end of the substrate and connected with an outer air pump. The invention further discloses a gripper prepared by the variable stiffness filler baggage device. The gripper comprises a fixing plate and a plurality of manipulator fingers connected at the lower end of the fixing plate, and each manipulator finger is provided with a variable stiffness filler baggage device. According to the gripper, stiffness of the air bag is pneumatically changed, so that the gripper can grab objects, grabbing modes of a traditional manipulator are replaced, the gripper is flexible and rapid in action, convenient to operate and wide in applicability, damage to articles is decreased, and articles of different sizes and types can be grabbed by adjusting air pressure of the air pump, the size of the air bag and the number of the manipulator fingers as required.

Owner:王泽宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com