Interdigital electrode material with vertical orientation three-dimensional structure and preparation method and application thereof

A technology of interdigitated electrodes and vertical orientation, which is applied in the field of interdigitated electrode materials and preparation, can solve problems such as difficult to control the composite state of materials and electrodes, and achieve good application prospects, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

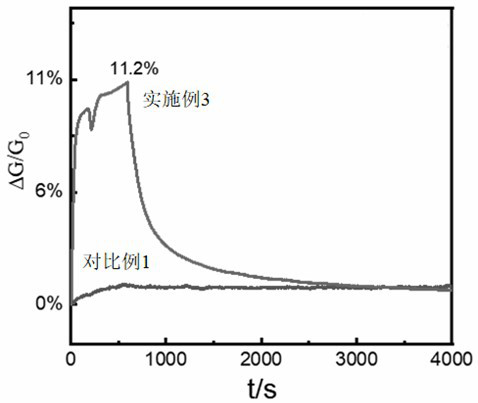

Examples

reference example 1

[0054] The pretreatment method of the interdigitated electrodes: respectively place the PET, PDMS, PI, and aluminum oxide interdigitated electrodes used in the embodiment of the present invention in absolute ethanol, and perform ultrasonic cleaning at a frequency of 28kHz and a power of 500W 2min, at 60°C, vacuum degree -0.1MPa, vacuum dry for 30min, and then perform surface plasma cleaning for 15min at a power of 15W, and it is ready.

Embodiment 1

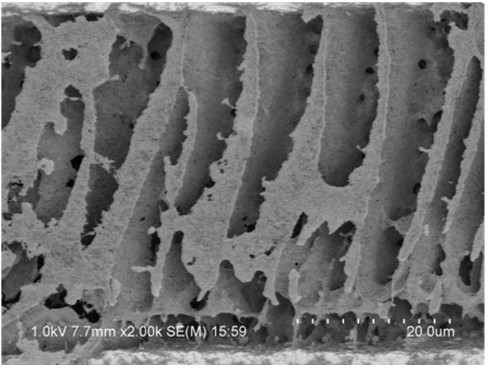

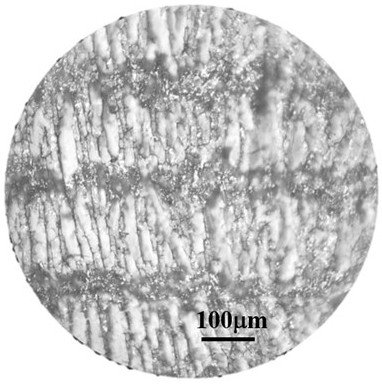

[0056] The interdigitated electrode material with a vertically oriented three-dimensional structure is composed of graphene oxide quantum dots stacked with a graphene oxide quantum dot sheet structure arranged at intervals between the fingers of the PET interdigitated electrode; The graphene oxide quantum dot material layer formed by the graphene oxide quantum dot layer structure has a thickness of 15 μm and a width of 55 μm, and the orientation angle of the nearly vertically oriented monolithic layers is 75°, between the nearly vertically oriented monolithic layers The vertical spacing between them is 10 μm, and the thickness of the monolithic layer is 0.5 μm; the thermal conductivity of the electrode layer material of the PET interdigitated electrode is 75W·m -1 ·K -1 , the surface of the PET substrate is flat and its thermal conductivity is 0.3W·m -1 ·K -1 , the thickness of the electrode layer of the PET interdigitated electrode is 15.5 μm, the line width is 45 μm, and t...

Embodiment 2

[0061] The interdigitated electrode material having a vertically oriented three-dimensional structure is composed of zinc oxide nanoparticle sheet structure formed by stacking zinc oxide nanoparticles and arranged at intervals between the fingers of the PET interdigitated electrode; the oxide The zinc oxide nanomaterial layer formed by the sheet structure of zinc nanoparticles has a thickness of 15 μm and a width of 55 μm, the orientation angle of the nearly vertically oriented monolithic layers is 75°, and the vertical distance between the nearly vertically oriented monolithic layers is 4 μm, the thickness of the monolithic layer is 0.3 μm; the thermal conductivity of the electrode layer material of the PET interdigitated electrode is 75W·m -1 ·K -1 , the surface of the PET substrate is flat and its thermal conductivity is 0.3W·m -1 ·K -1 , the thickness of the electrode layer of the PET interdigitated electrode is 15.5 μm, the line width is 100 μm, and the line spacing is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com