Manual hydraulic carrying vehicle

A truck and hydraulic technology, which is applied to handles, vehicle parts, transportation and packaging, etc., can solve the problems of being unable to quickly approach the loading and unloading station, inflexible vehicle steering, and affecting construction speed, so as to shorten the turning time and move Flexible and fast, reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

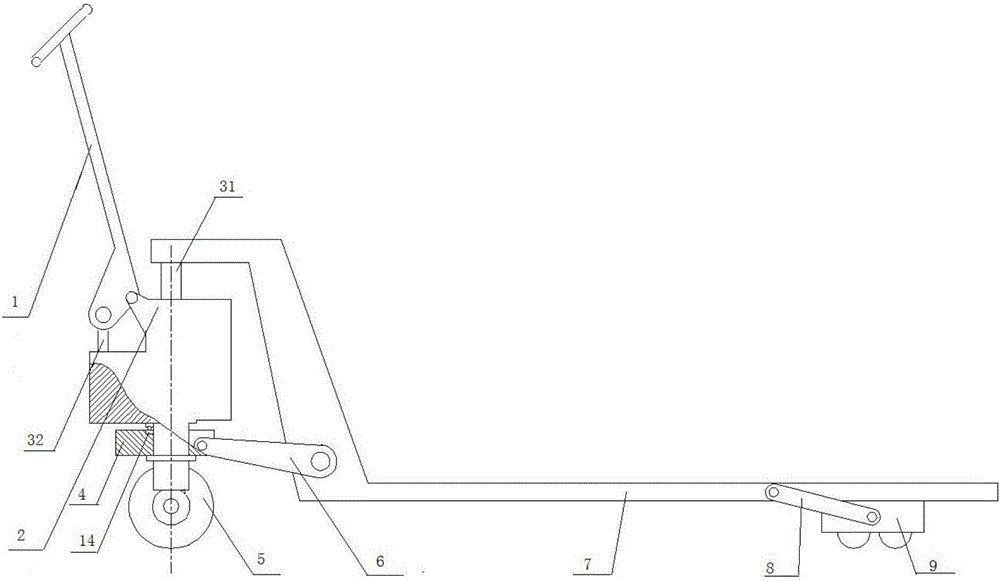

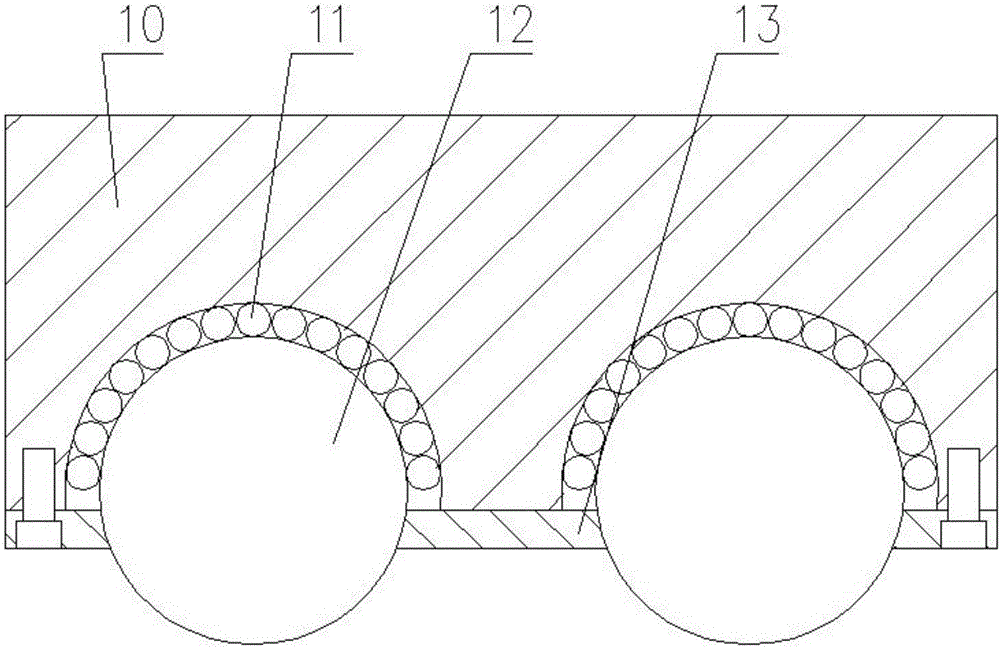

[0017] Such as figure 1 As shown, the manual hydraulic truck includes handle 1, oil cylinder body 2, large piston rod 31, small piston rod 32, support body 4, rear wheel 5, rear connecting rod 6, car body 7, front connecting rod 8, front Support body 9 ; the vehicle body 7 is hinged to the support body 4 through the rear connecting rod 6 , and the front support body 9 is hinged to the vehicle body 7 through the front connecting rod 8 .

[0018] The inside of the oil cylinder body 2 is actually a hydraulic jack, and a large oil cylinder and a small oil cylinder are arranged. The large oil cylinder and the small oil cylinder are connected. , one end of the small piston rod 32 is connected with the small oil cylinder, and the other end stretches out from the top of the oil cylinder body 2. When the external force drives the small piston rod 32 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com