Sand spraying pipe for locomotive sand sprayer

A technology of sand spreading device and sand spreading pipe, which is applied in the direction of locomotives, etc. It can solve the problems of loose sand spreading pipe, loose clamp, inconvenient disassembly, etc., so as to prevent rain and snow water from entering the sand spreading pipe, reduce waste, and disassemble convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the technical scheme of the sand spreading pipe for the locomotive sand spreading device provided by the present invention will be further described in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

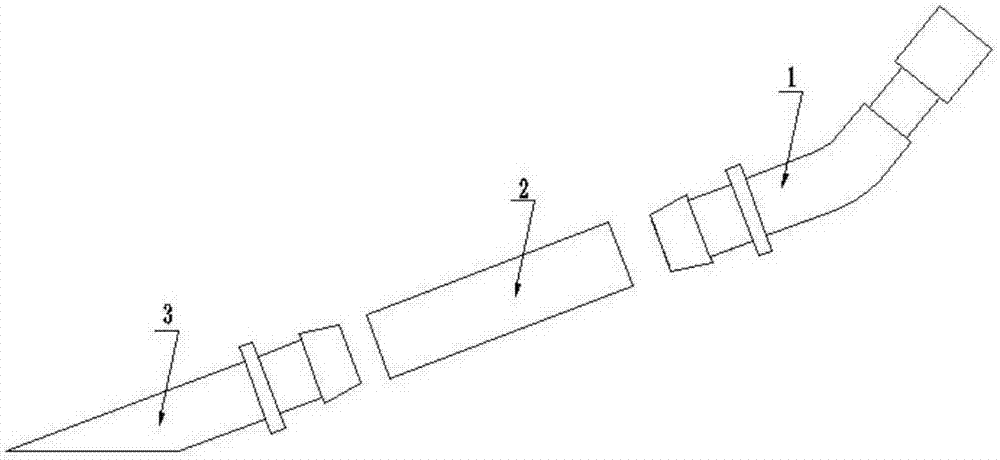

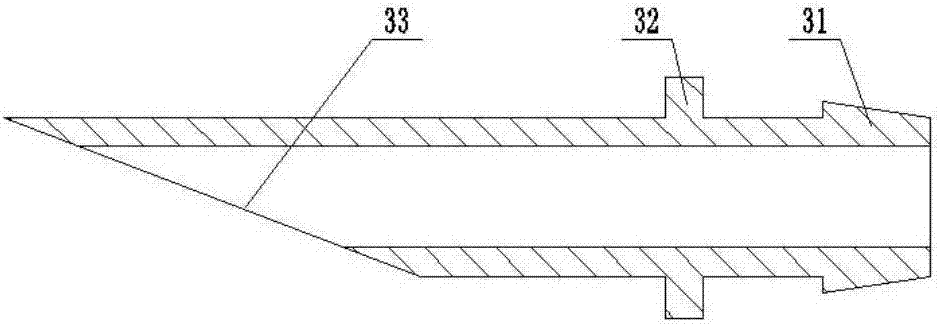

[0025] see figure 1 and figure 2 , the locomotive sand sprinkler provided by the present invention is provided with a sand pipe, including a connecting piece 1, a connecting hose 2 and a sand outlet steel pipe 3. One end of the connecting pipe 1 is connected with the locomotive sand spreader, the other end is connected with the sand sprinkler hose 2, and the other end of the sand sprinkler hose 2 is connected with the sand outlet steel pipe 3.

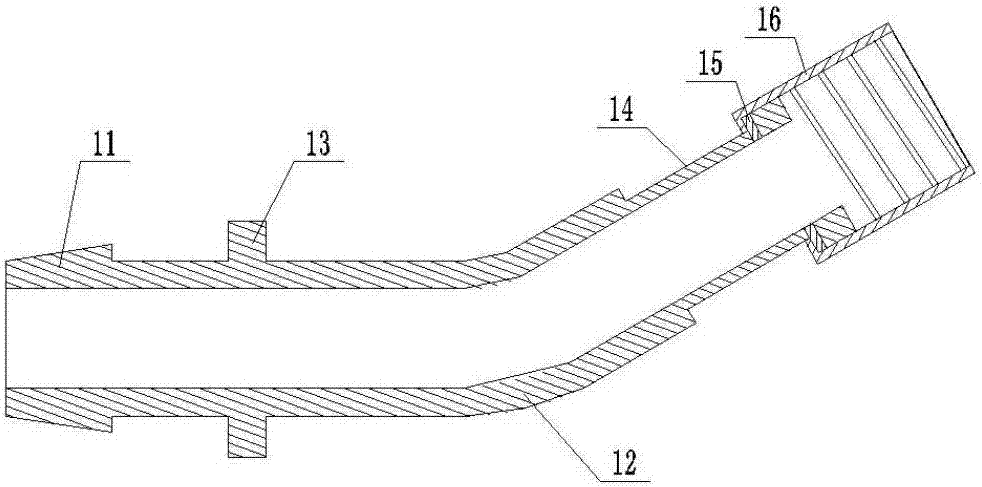

[0026] The connector 1 is a hollow tube, one end is provided with a trapezoidal boss 11, and a limiting boss 13 is arranged near the trapezoidal boss 11; the other end near the connector 1 has an annular groove 14, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com