Lifting mechanism and range hood applying same

A lifting mechanism and a range hood technology, applied in the application, removal of oil fume, household stoves, etc., can solve the problems of the smoke guide plate moving not smoothly, poor user experience, etc., and achieve the effect of eliminating jitter and preventing weightlessness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

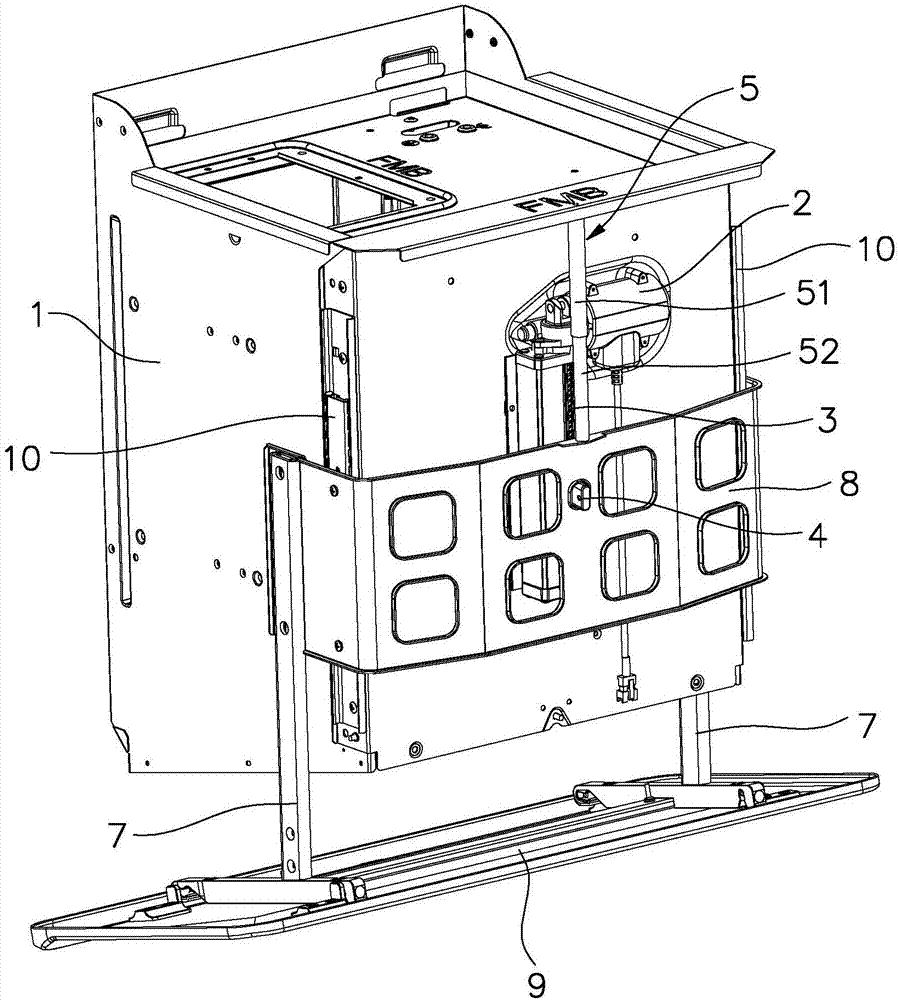

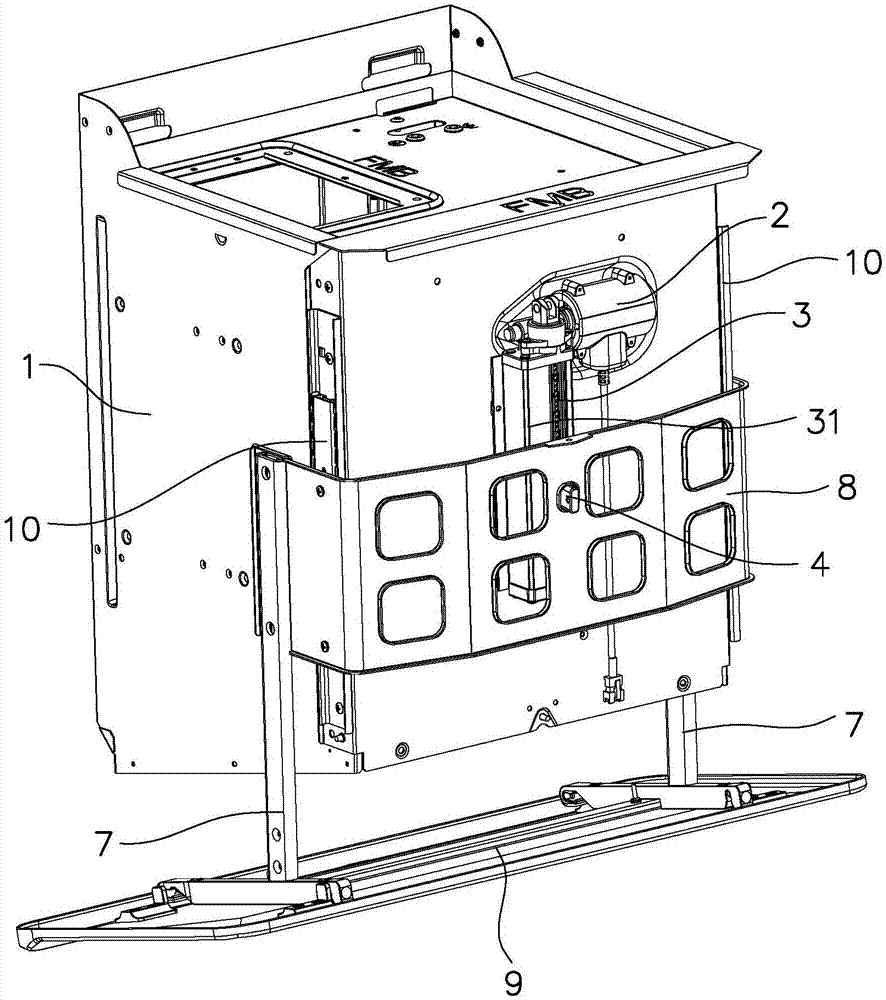

[0022] Such as figure 1 As shown, the lifting mechanism in this embodiment is installed on the range hood, and the lifting mechanism includes a mounting frame 1 , a driving motor 2 , a screw rod 3 and a nut 4 . Wherein, the fan housing constitutes the mounting frame 1, the driving motor 2 is installed on the mounting frame 1, the screw mandrel 3 is vertically arranged and rotates under the driving of the driving motor 2, and the nut 4 is installed on the screw mandrel 3. The range hood includes a fan cover, lifting rod 7, U-shaped connecting plate 8 and smoke guide plate 9, the lifting rod 7, U-shaped connecting plate 8 and smoke guiding plate 9 constitute the load of the lifting mechanism, and the load is installed on the nut 4 And with the nut for synchronous lifting movement.

[0023] The lifting mechanism includes a one-way damping device. When the lifting mechanism is in a descending state, the one-way damping device can generate a damping force on the screw rod 3 to off...

Embodiment 2

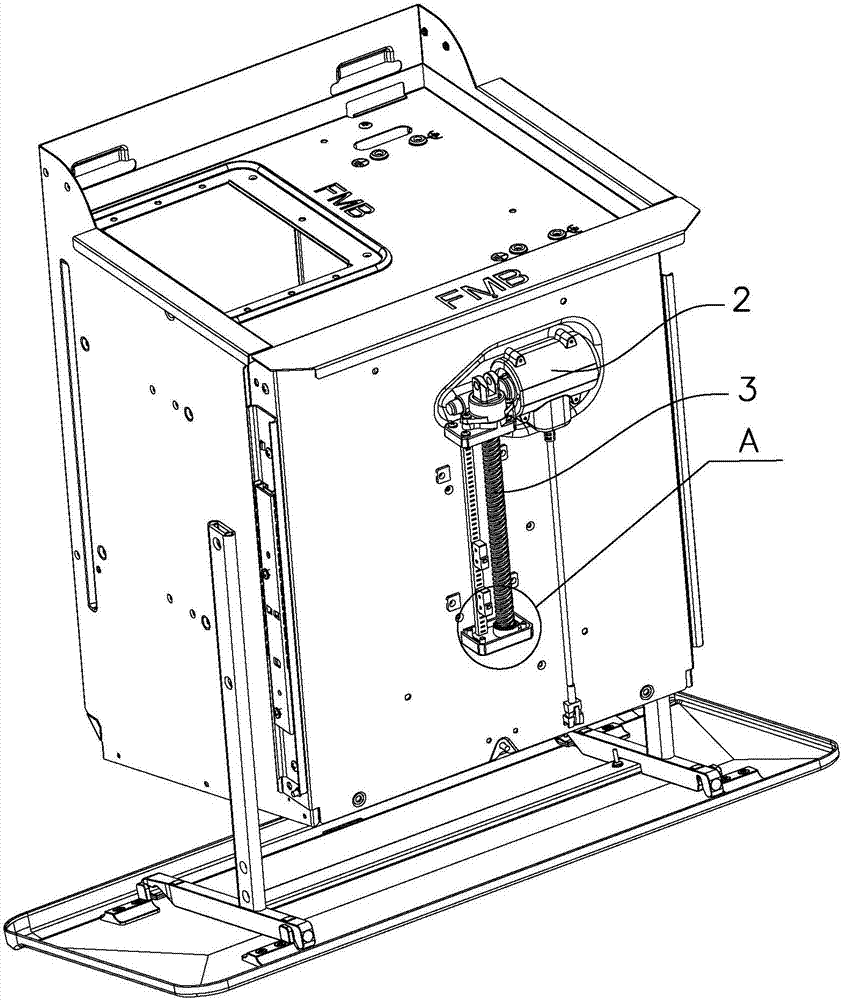

[0027] Such as Figure 2 to Figure 4 As shown, the one-way damping device of this embodiment adopts a one-way rotary damper 6, and the one-way rotary damper 6 is installed on the screw mandrel 3. Specifically, a screw mandrel protective cover 31 is installed outside the screw mandrel 3. The bottom of the screw mandrel protective cover 31 is provided with a screw mandrel mounting seat 32 , and the one-way rotation damper 6 is arranged in the screw mandrel mounting seat 32 .

[0028] When working, when the lifting mechanism rises, the one-way rotation damper 6 does not generate a damping force, and when it descends, it generates a damping force on the screw rod 3. This damping force can just eliminate the influence of the gravity of the load end on the screw rod, so that the mechanism can operate under load. When descending, it will not be in the state of "weightlessness", avoiding the resulting vibration and abnormal sound, and then helping the smoke deflector 9 to maintain a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com