Upper cover stop structure of washing machine and full-automatic washing machine

A washing machine and stopper technology, applied in the field of washing machines, can solve the problems of affecting the appearance of the lid, poor safety, large structure, etc., and achieve the effects of eliminating potential safety hazards of electrical components, saving production costs, and simple buckle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

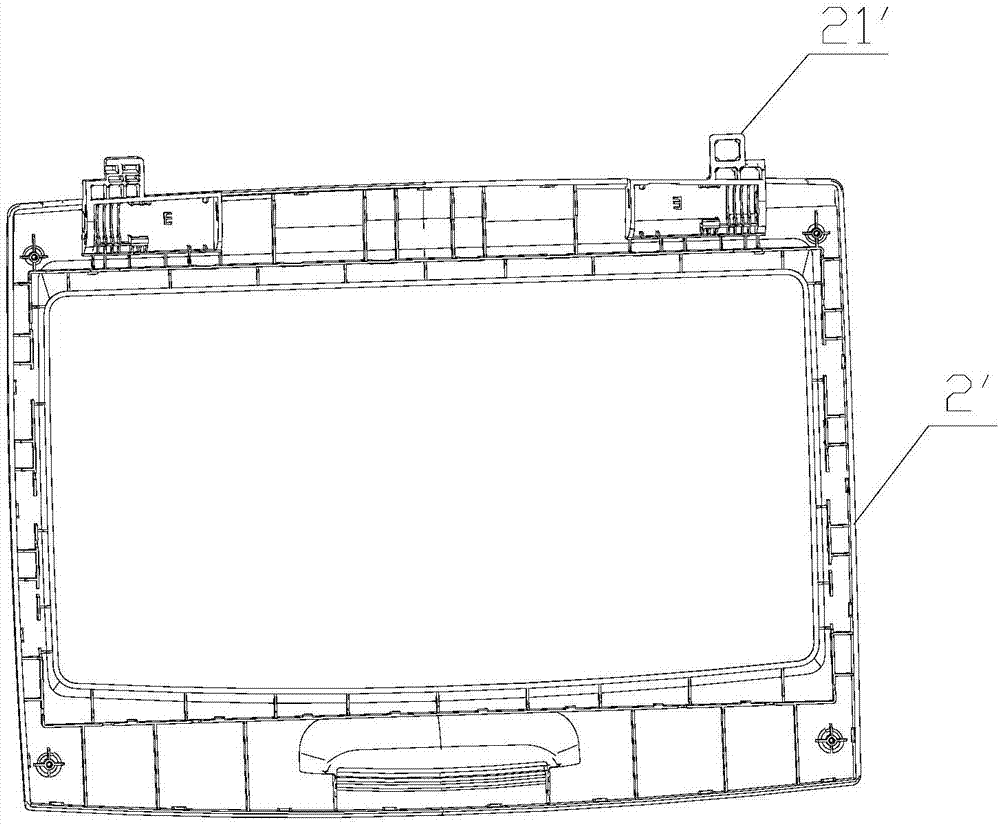

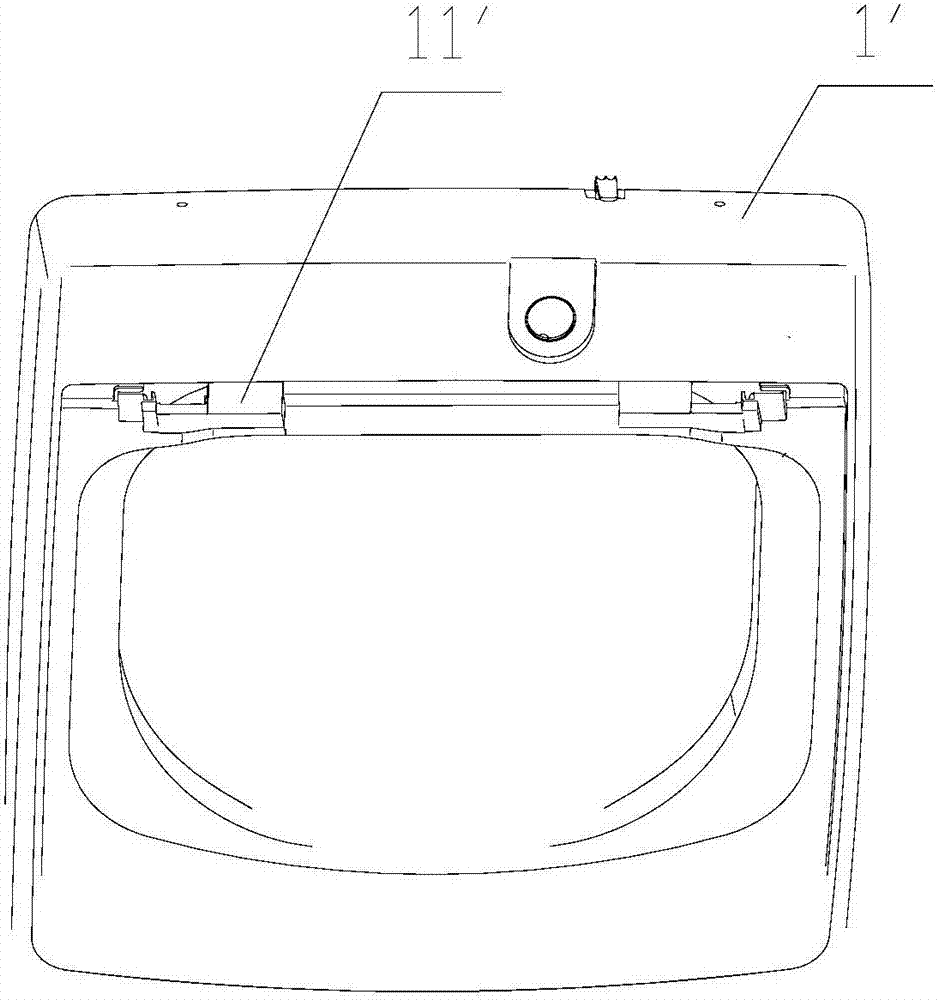

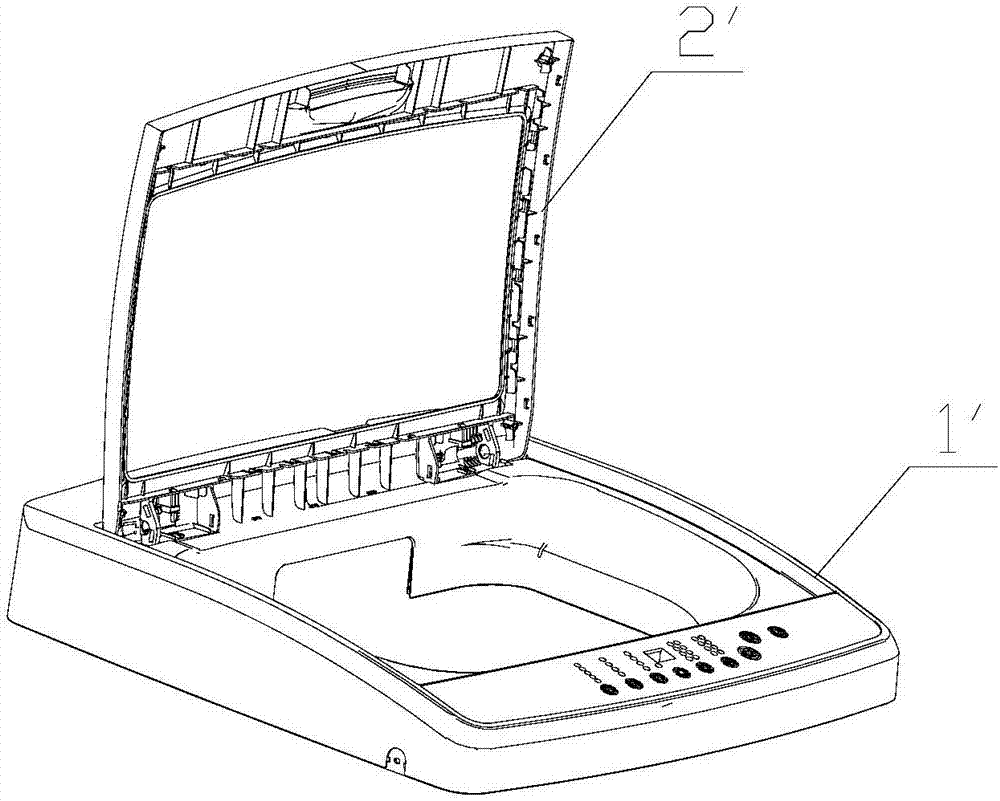

[0030] Such as Figure 4-Figure 6 As shown, this embodiment provides a preferred washing machine upper cover stop structure, which includes a control panel base 1 and an upper cover 2, and one end of the upper cover 2 is reversibly arranged on one end of the control panel base 1, wherein the upper cover The lower surface of 2 is provided with at least one buckle 21 in an array near the end, and the control panel base 1 is provided with at least one buckle seat 11 compatible with the buckle 21; when the upper cover 2 is opened away from the control panel base 1 The buckle 21 can be driven to rotate until the buckle 21 abuts against the buckle seat 11 .

[0031] In the present invention, the buckle 21 is arranged on the upper cover 2, and the buckle seat 11 matched with the buckle 21 is arranged on the control panel base 1, so that the originally static raised structure becomes movable, so that the washing machine upper cover 2 is completely When opening, the moving buckle 21 a...

Embodiment 2

[0039] This embodiment proposes a washing machine top cover stopper structure, which is basically similar to the washing machine top cover stopper structure described in Embodiment 1, the difference lies in:

[0040] A hinge is provided between the loam cake 2 and the control panel seat 1, and the loam cake 2 and the control panel seat 1 are rotatably connected through the hinge. In this embodiment, the hinge structure is used to realize the opening and closing of the upper cover 2 of the washing machine. The structure is simpler, the use is more convenient, and the movement is stable and reliable, which is conducive to popularization and application. When the upper cover 2 is fully opened, a row of buckles 21 on the upper cover 2 is just hooked by a row of buckle seats 11 on the control panel base 1, thereby playing a stop effect.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap