High pressure oil output device and control method thereof

A technology of output device and high-pressure oil, which is applied in the direction of pump control, engine parameters, pump parameters, etc., can solve the problems of intermittent high-pressure oil, the height can only be around 1Mpa-2Mpa, and poor continuity, so as to achieve enhanced accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

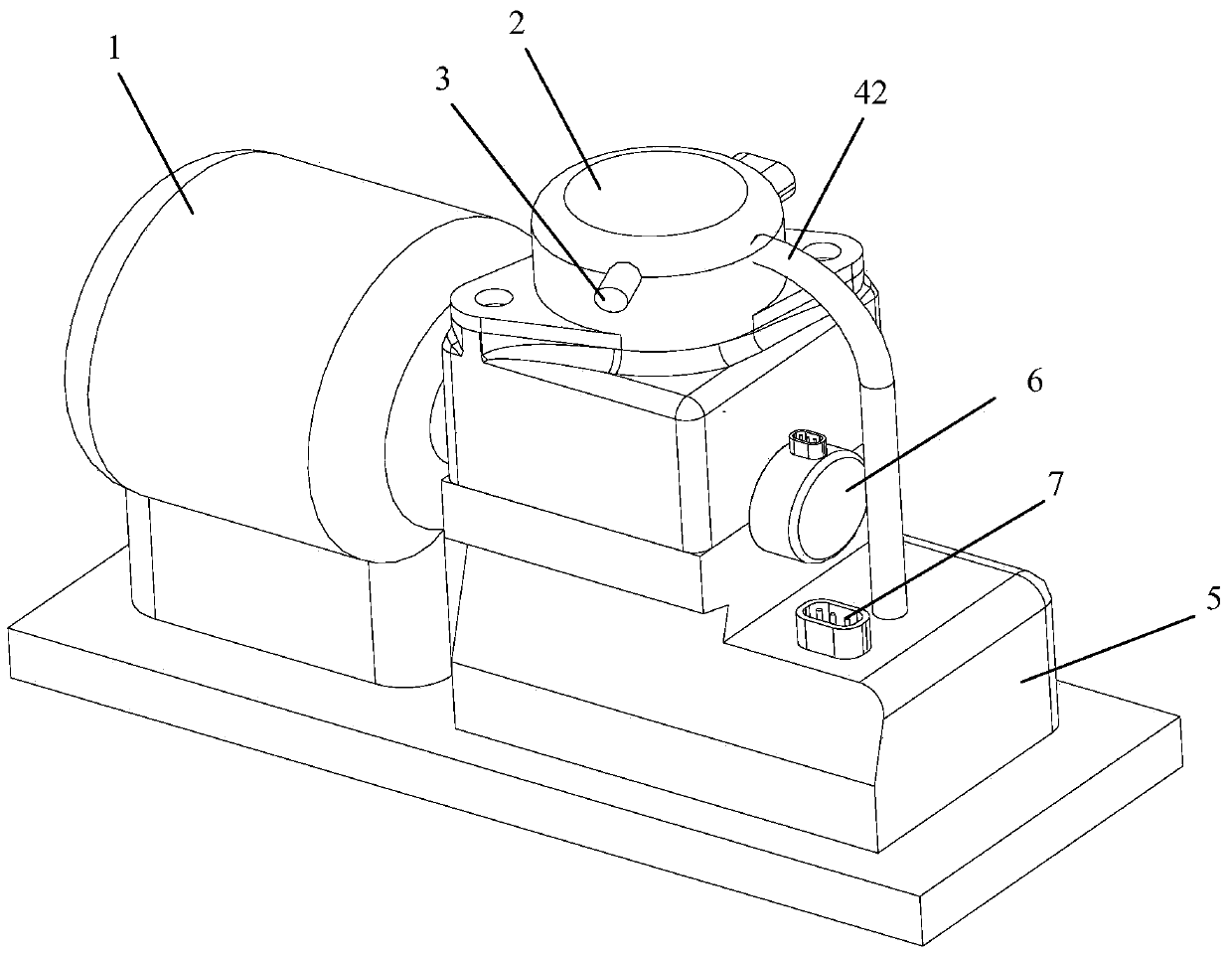

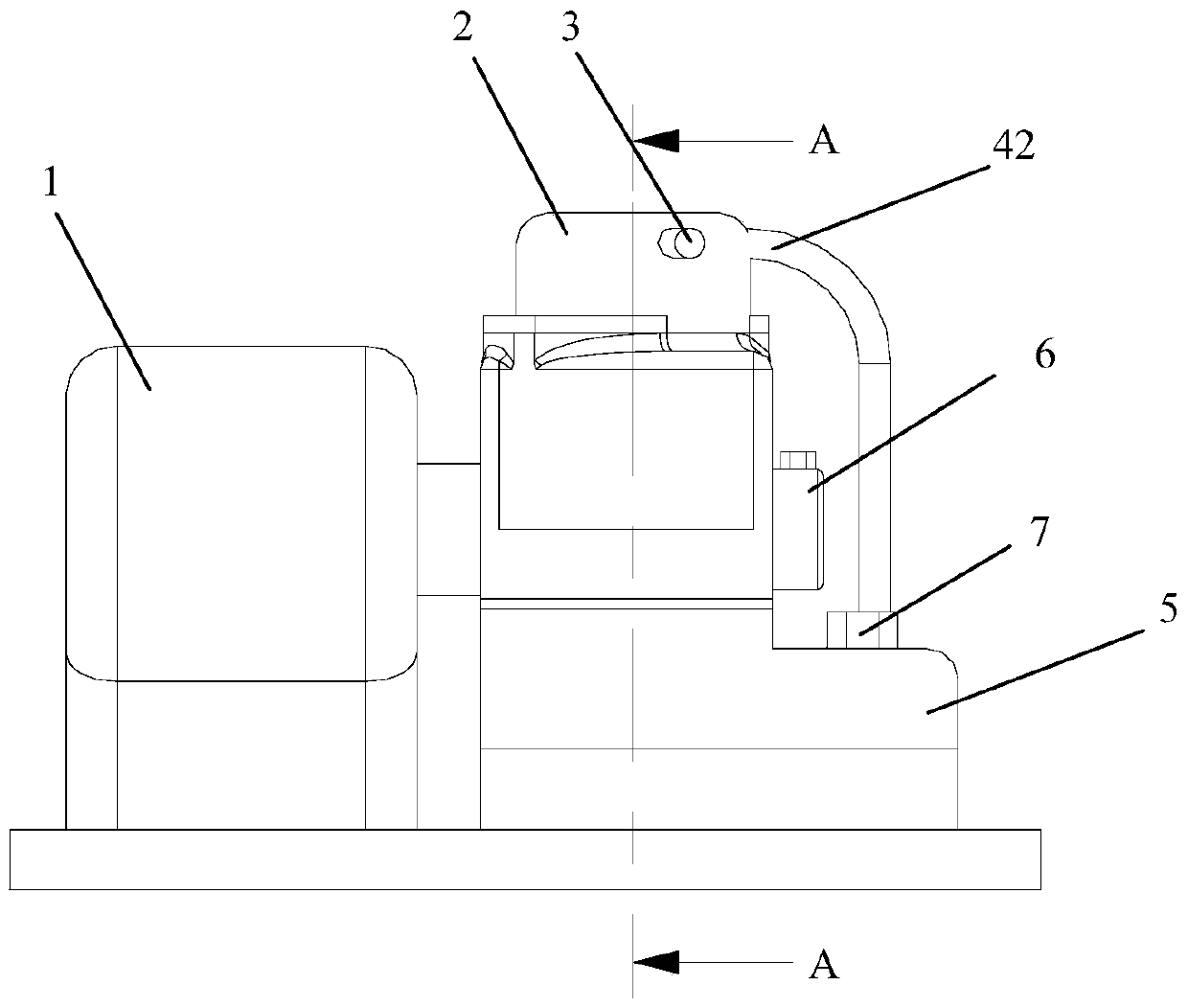

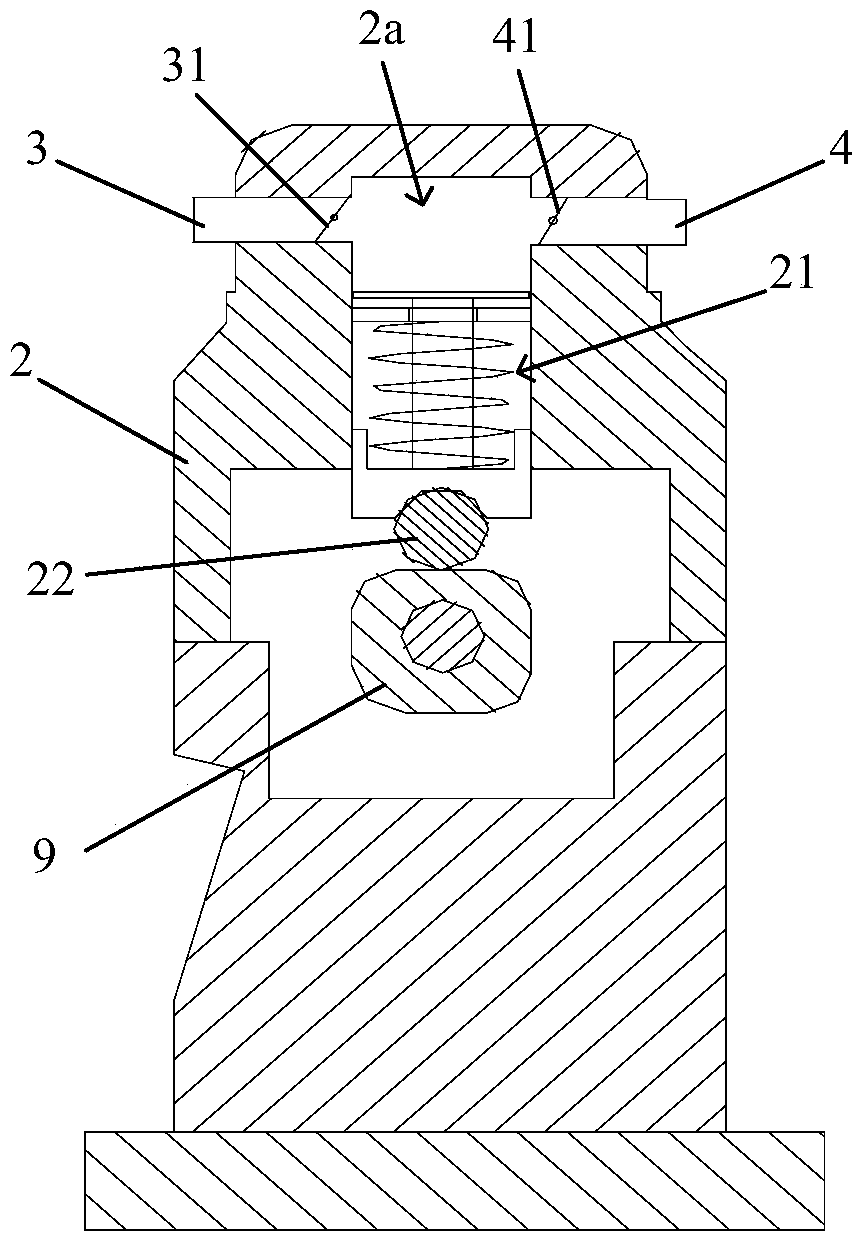

[0042] An embodiment of the present invention provides a high-pressure oil output device, referring to figure 1 , figure 2 As shown, the high-pressure oil output device includes:

[0043] Motor 1, as a power source;

[0044] The camshaft 8 is connected to the output end of the motor 1 and driven by the motor 1 to rotate;

[0045] The plunger pump 2 is driven by the camshaft 8 to reciprocate, so as to compress the low-pressure oil entering the plunger pump 2 into high-pressure oil;

[0046] The high-pressure oil chamber 5 is connected with the oil outlet 4 of the plunger pump 2 for containing high-pressure oil, and the oil outlet communicates with the high-pressure oil chamber 5 through the oil pipe 42;

[0047]The control module (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com