Composite loading test device of torsion and cutting of air spring

An air spring, composite loading technology, used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems affecting test reliability, inability to conduct stiffness tests, and no feedback of displacement and load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

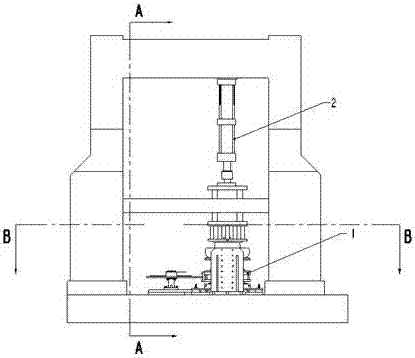

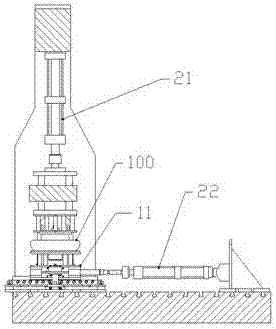

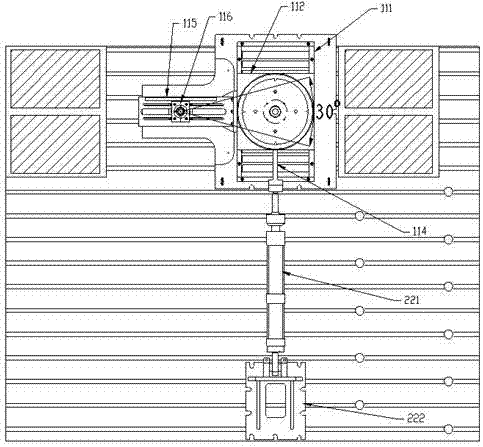

[0029] Such as Figure 1 to Figure 7 As shown, the air spring torsion and shear composite loading test device is composed of a simulated bogie device 1 and a simulated car body device 2. Both the simulated car body device 2 and the simulated bogie device 1 are installed on a horizontal workbench. The bogie device 1 includes a horizontally arranged crank-rod swing workbench 11, and the simulated car body device 2 includes a vertical oil cylinder assembly 21 erected directly above the crank-connect rod swing workbench 11 and a The horizontal oil cylinder assembly 22, the horizontal oil cylinder assembly 22 is arranged along the front and back direction of the crank connecting rod swing worktable 11, the air spring 100 is clamped between the vertical oil cylinder assembly 21 and the crank connecting rod swing workbench 11, the horizontal oil cylinder asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com