Combined water cup

A combination type, water cup technology, applied in the direction of drinking water containers, etc., can solve the problems of inconvenience, time-consuming and laborious, uneven mixing of water cups, etc., to prevent damage, improve safety, and realize the effect of automatic take-off and landing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

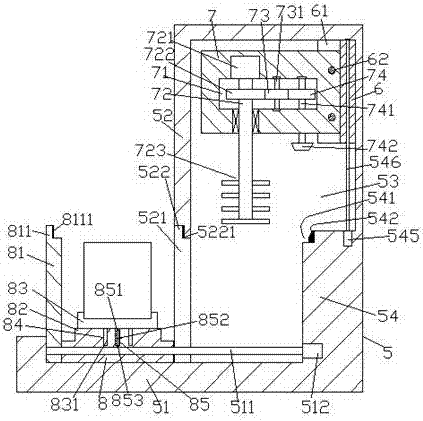

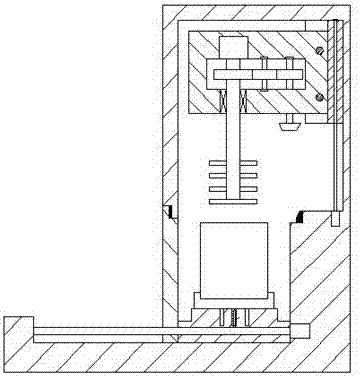

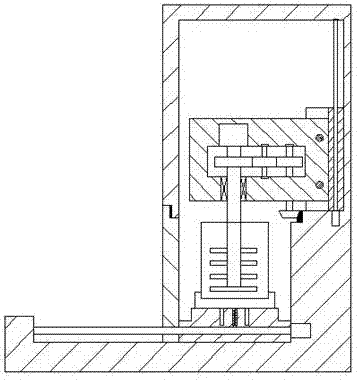

[0021] Such as Figure 1-Figure 4 As shown, a combined water cup of the present invention includes a mixer body 5 composed of a base 51 and a housing 52, the housing 52 is provided with a stirring chamber 53, and the left side of the housing 52 is adjacent to the One side of the base 51 is provided with a passage groove 521, and the right side of the stirring chamber 53 opposite to the right side of the passage groove 521 is fixedly provided with a convex portion 54, and the top of the left side of the convex portion 54 is provided with a groove extended from front to back part 541, the right side of the groove part 541 is fixedly provided with a tapered surface rack 542 extended along the front and rear extension direction of the groove part 541, and the top surface of the convex part 54 far away from the groove part 541 is provided There is a first screw rod 546 extended upwards, and the first screw rod 546 is mated with a landing gear 6 whose right side abuts against and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com