Aerodynamic shape design method of waverider in kiss-cut flow field with variable shock wave angle

A technology of aerodynamic shape and design method, applied in aircraft parts, ground installations, transportation and packaging, etc., can solve the problem of limited freedom of waverider shape design, achieve enhanced shape practicability, widen design freedom, and increase design Effects of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

[0031] The invention proposes a waverider design method for a kiss-cut flow field with variable shock wave angle. The method is an extension of the existing kiss-cut cone method, and improves the design freedom of the waverider when the shock angle changes.

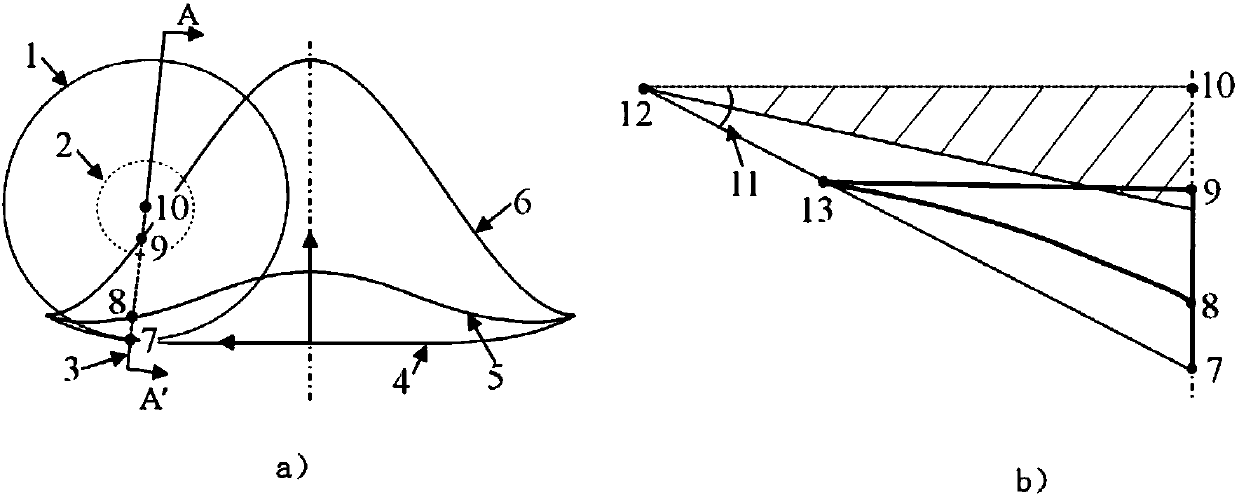

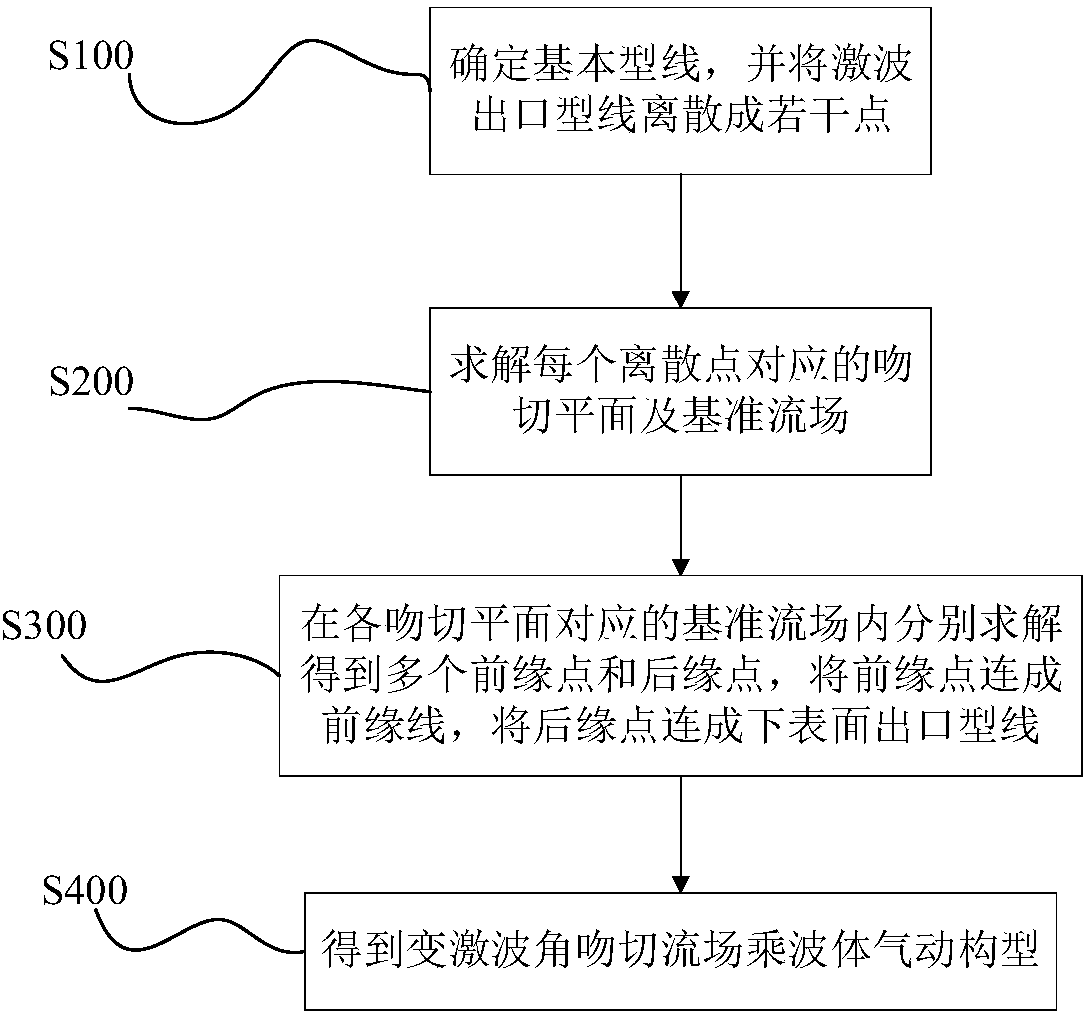

[0032] see figure 2 , the waverider design method of variable shock wave angle kiss-cut flow field provided by the present invention comprises the following steps:

[0033] Step S100: Determine the basic profile of the waverider in the kiss-cut flow field with variable shock angle, and discretize the shock exit profile in the basic profile into several points;

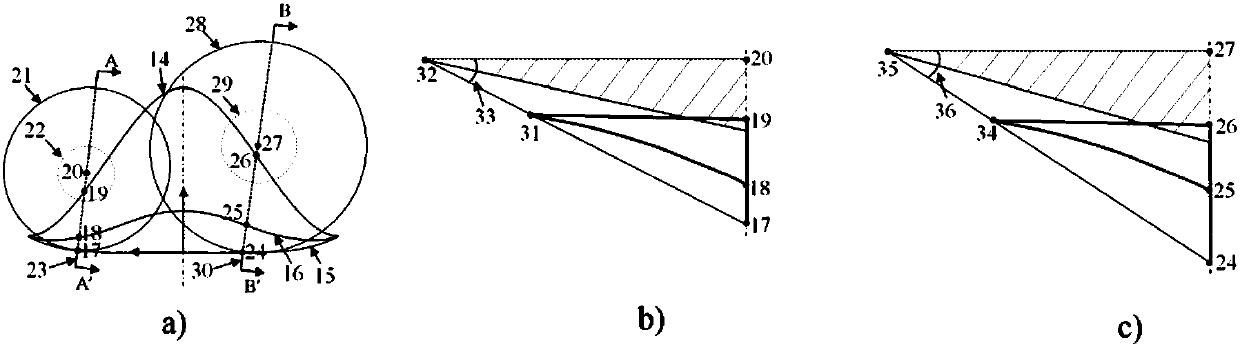

[0034] like image 3 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com