A centrifugal clutch, a speed control system and a motorcycle

A technology for centrifugal clutches and motorcycles, applied in clutches, automatic clutches, mechanical equipment, etc., can solve the problems of reducing the sliding distance of motorcycles and prone to frustration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

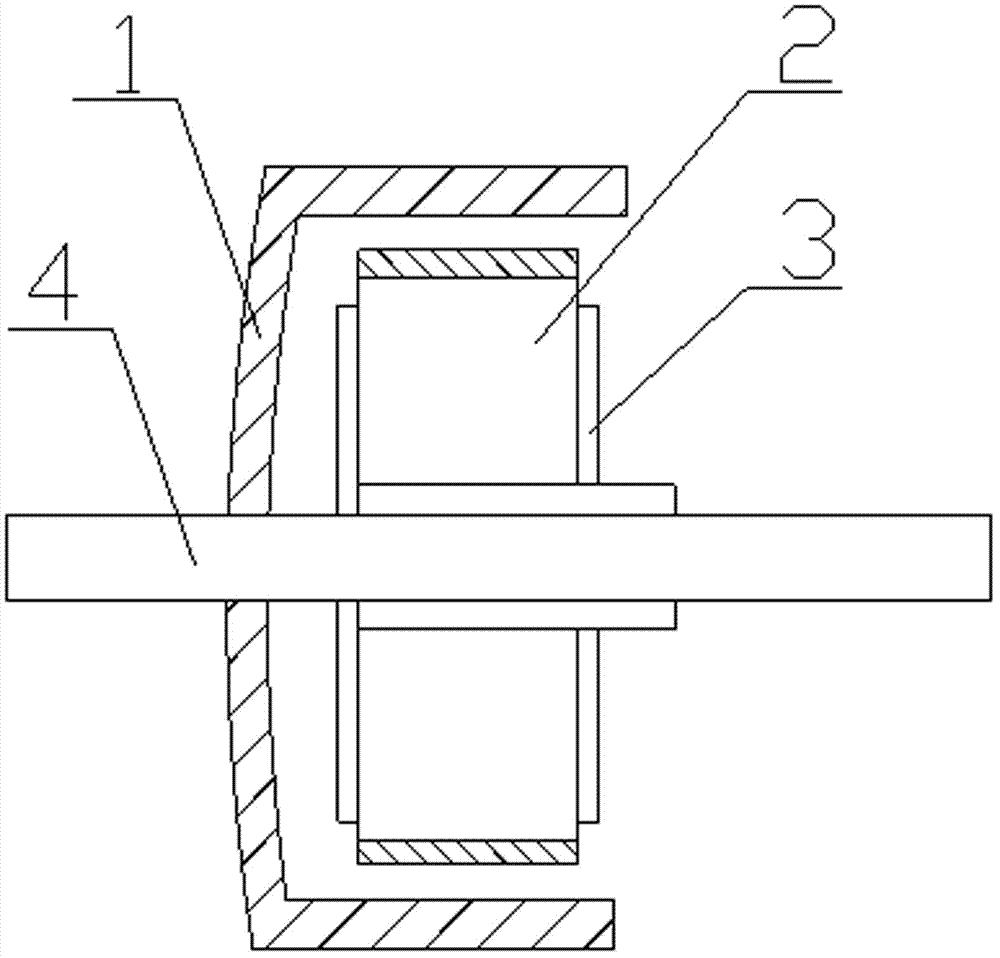

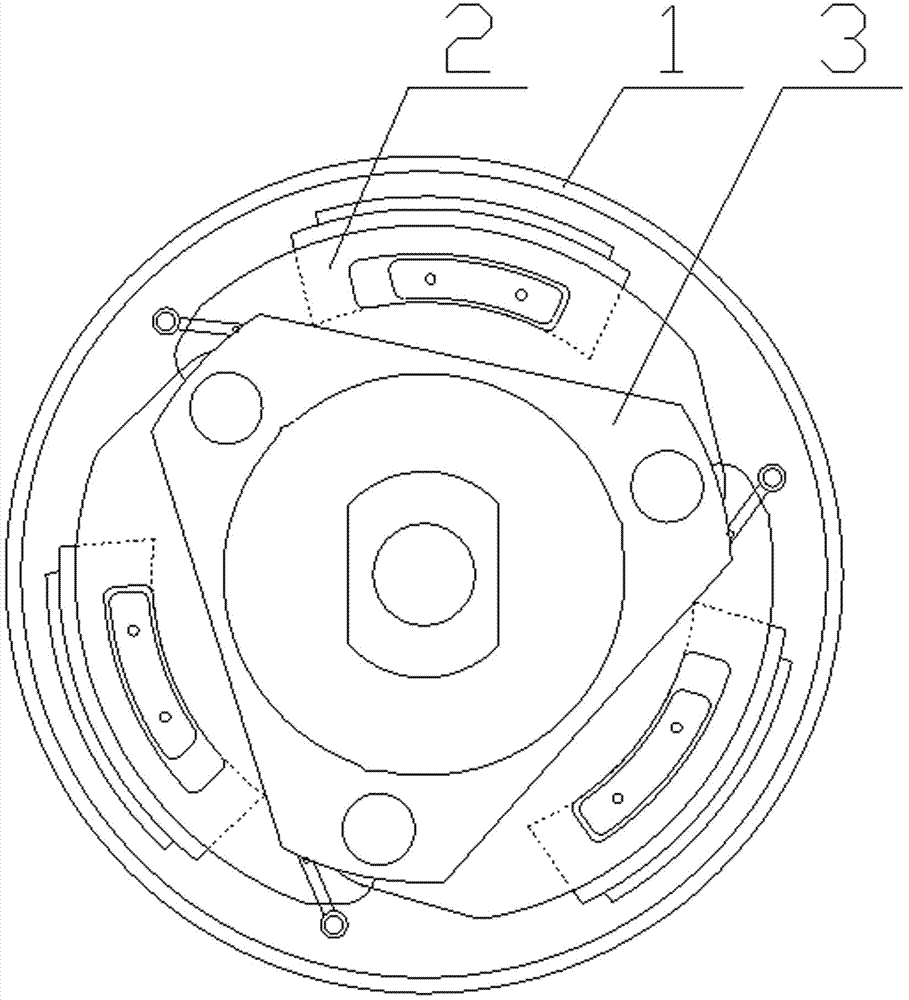

[0038] Such as figure 1 , 2 As shown, a centrifugal clutch includes a clutch housing 1 and a plurality of centrifugal shoes 2 arranged inside the clutch housing 1. The clutch housing 1 is composed of a cylindrical portion and a bottom plate covering one end of the cylindrical portion, usually approximately It is bowl-shaped, and the bottom plate of the clutch housing 1 is fixedly installed on the output shaft 4; multiple centrifugal shoes 2 are hinged on the cage 3 through pin shafts, and the adjacent centrifugal shoes 2 are connected by springs, and the cage 3 passes through The shaft sleeve is installed on the output shaft 4.

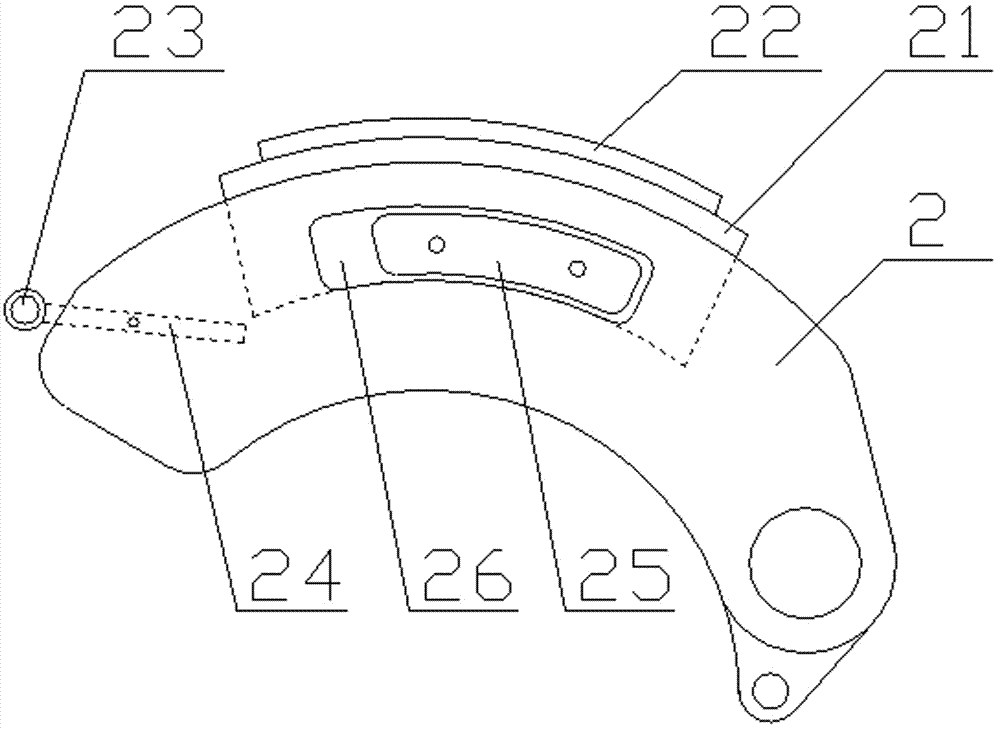

[0039] Such as image 3 , 4 As shown, the centrifugal shoe 2 has an outer arc surface and two end faces, the outer arc surface of the centrifugal shoe 2 is inlaid with a movable block 21, and the movable block 21 can move along the length of the centrifugal shoe 2. Limit movement in the direction, a return spring (not shown in the figure) is insta...

Embodiment 2

[0043] Compared with Embodiment 1, the overall structure of the clutch in this embodiment is basically the same, and the working process and principle are also the same. The main difference is that the connection structure and method between the centrifugal shoe block 2 and the movable block 21 are different. It is inlaid on the outer arc surface of the centrifugal shoe block 2, while the movable block 21 in this embodiment is sleeved on the outer arc surface of the centrifugal shoe block 2.

[0044] Such as Figures 7 to 10 As shown, in this embodiment, symmetrical arc-shaped grooves 25 are respectively provided on the two end surfaces of the centrifugal shoe block 2 or arc-shaped through holes 25 are provided through the two end surfaces. The arc-shaped grooves or arc-shaped The radian of the through hole 25 is the same as that of the outer arc surface of the centrifugal shoe block 2; Above, the lower part of the movable block 21 is provided with a limiting block 26 protrud...

Embodiment 3

[0046] Such as Figure 11 The transmission system shown includes a driving wheel assembly A, a driven wheel assembly B, a transmission belt C, and a clutch D. The clutch D is the centrifugal clutch described in Embodiment 1 or 2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com