Flip type vacuum wall breaking machine

A vacuum wall breaker and flip-top technology, which can be used in household appliances, applications, kitchen appliances, etc., can solve the problems of high manufacturing cost, increased transportation cost, difficult to clean, etc., and achieve the effect of wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

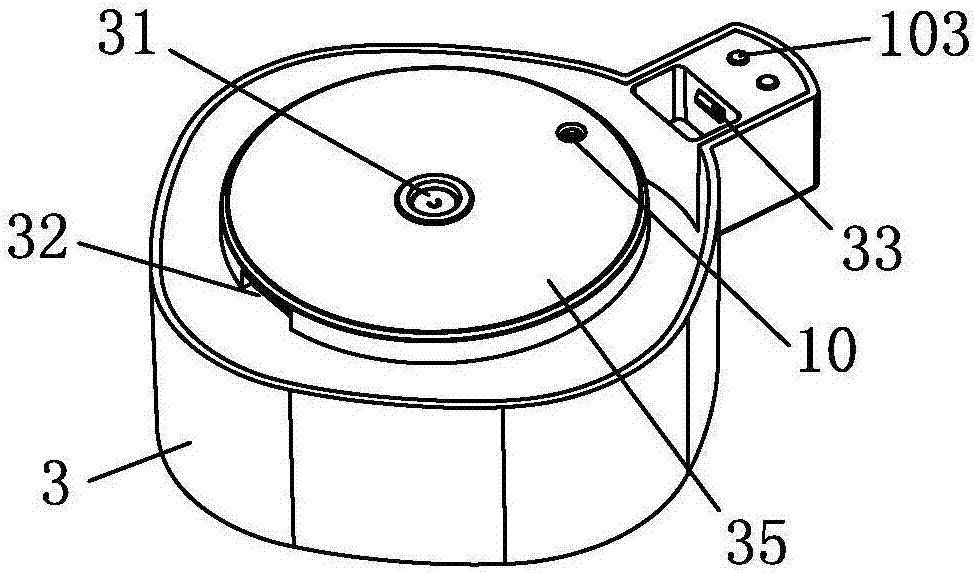

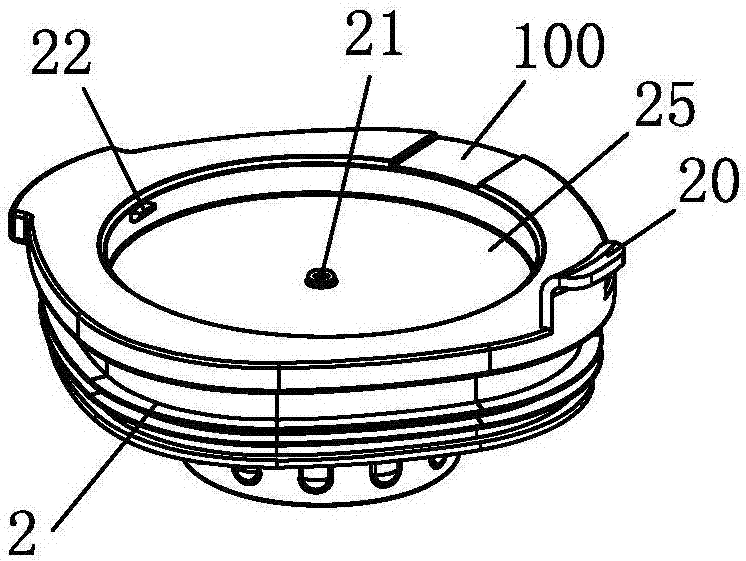

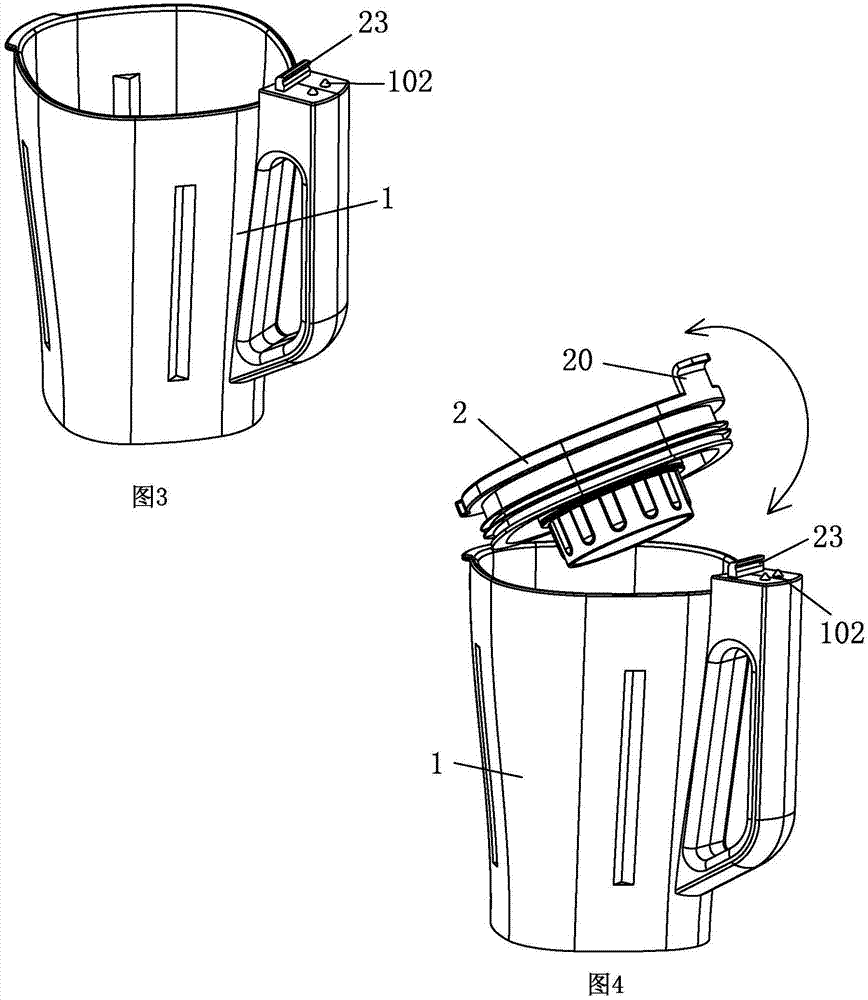

[0041] see Figure 1-Figure 6 , the clamshell vacuum breaker includes a cup body 1, a cover body 2 and a vacuum device 3, the cover body 2 is sealed and connected to the cup body 1, and the cover body 2 is provided with an air vent communicating with the cup body 1 Nozzle 21; the vacuum device 3 is detachably assembled with the cover body 2 through the flip mechanism, the flip mechanism includes a fastening part and a flip support part, and the fastening part is arranged on the vacuum device 3 and the cup body 1 close to the cup body 1 On one side of the handle, the flip support part is arranged on the side of the cover body 2 and the vacuum device 3 opposite to the handle of the cup body 1. One side of the vacuum device 3 is flipped on the cover body 2 through the flip support part, and the other side is fastened part and the cover body 2 are detachably assembled, the cover body 2 and the vacuum device 3 are independent of each other, and they can be disassembled by flipping,...

no. 2 example

[0052] see Figure 7-Figure 10 , the main difference between this clamshell vacuum breaker and the first embodiment is that the elastic lock tongue 23 elastically moves in the handle (or cover 2) of the cup body 1, and the handle (or cover body 2) of the cup body 1 The body 2) is provided with a button 101 for driving the elastic lock tongue 23 to move, and the elastic lock tongue 23 can be unlocked by pressing the button 101, so that the vacuum device 3 can be removed from the cover body 2 more easily.

[0053] Other unmentioned parts are the same as the first embodiment and will not be repeated.

no. 3 example

[0055] see Figure 11-Figure 16 The main difference between this clamshell vacuum breaker and the first embodiment is that the clamshell support part does not include the support buckle 22 (or support shaft) provided on the cover body 2, and the vacuum device 3 The buckle hole 32 (or hook) on the cover only includes the limit cavity 25 recessed on the cover body 2, and the limit platform 35 protruded on the vacuum device 3, and only one of them needs to be used for the flip support part. The technical solution can meet the operation requirements of the flip cover.

[0056] In this embodiment, the vacuum device 3 and the cover body 2 can also be separated or closed by pulling up and down, which can be understood by those skilled in the art.

[0057] The fastening part includes a lock post 24 set on the handle of the cup body 1 (or cover body 2), and a lock hole 34 set on the vacuum device 3, the two are connected by a tight fit, and naturally lock after being inserted into eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com