Magnetic steel automatic feeding and attaching mechanism

A technology of automatic feeding and pushing mechanism, which is applied in the direction of conveyors, conveyor objects, metal processing, etc., can solve the problems of low feeding and assembly efficiency, damage to magnetic steel, etc., to achieve convenient feeding methods and ensure feeding efficiency , strong continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

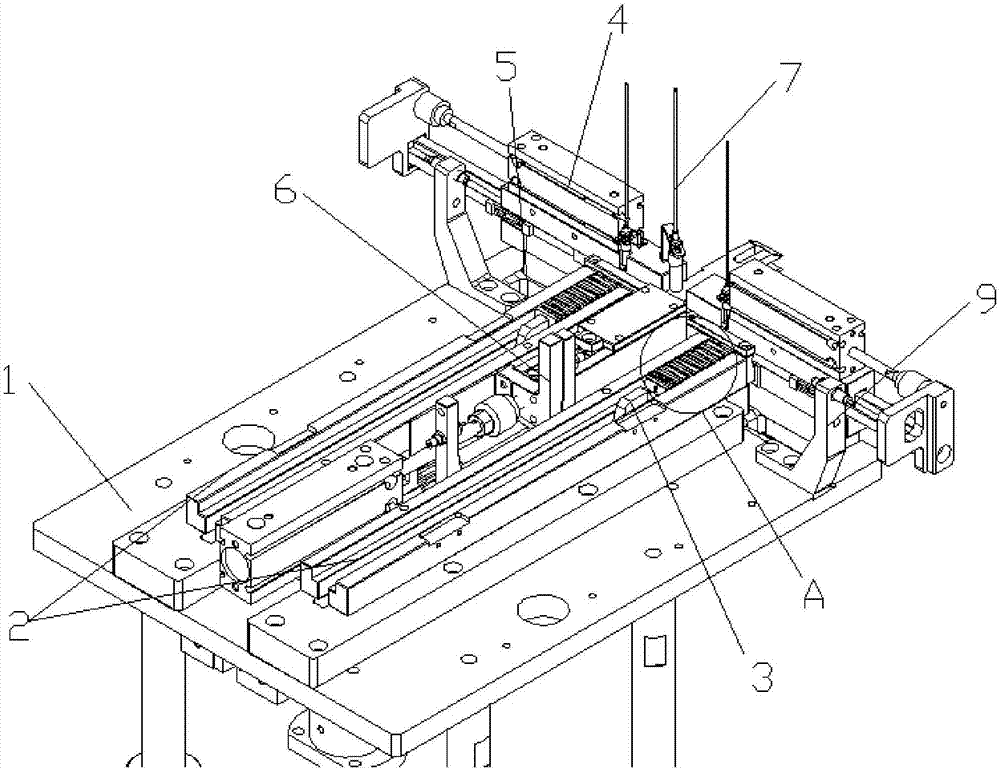

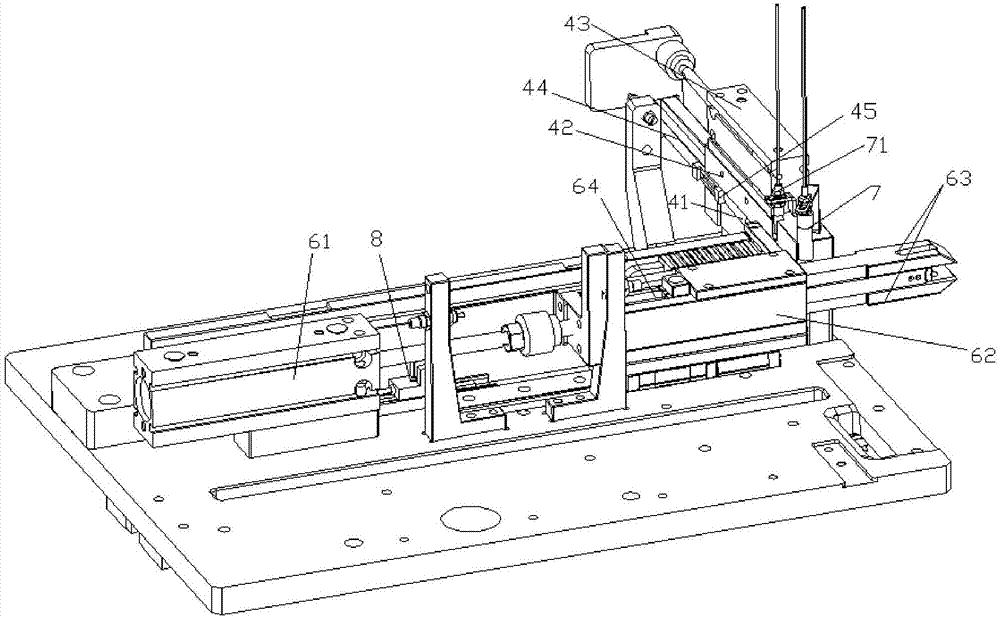

[0032] see Figure 1 to Figure 3 , this embodiment shows a magnetic steel automatic feeding and bonding method;

[0033] Specific steps are as follows:

[0034] 1) Place the S-pole magnet and N-pole magnet through the spacer and place them in the feeding channel 2;

[0035] 2) The pushing mechanism 3 pushes the magnetic steel, and pushes the magnetic steel into the feeding mechanism 4;

[0036] 3) The feeding mechanism 4 pushes the magnetic steel into the bonding mechanism 6;

[0037] 4) The bonding mechanism 6 pushes the magnetic steel to carry out the bonding step;

[0038] The number of feeding channels is two and symmetrically arranged on the frame 1;

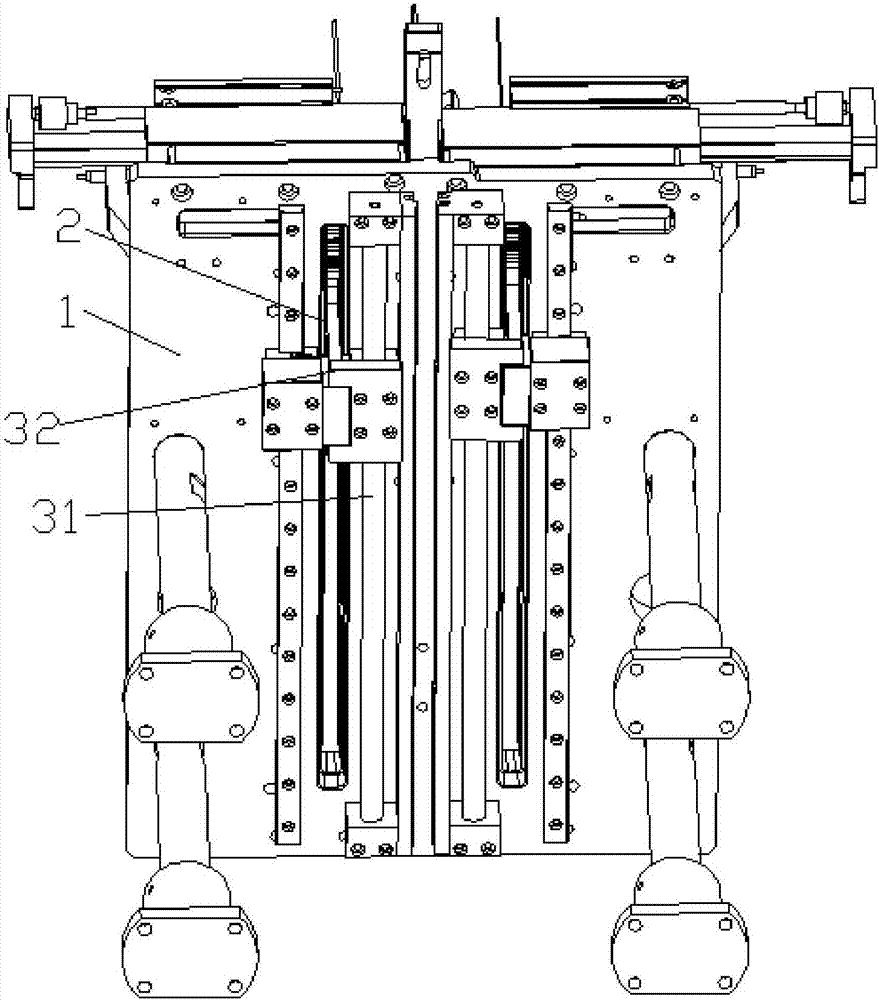

[0039] The pusher mechanism 3 includes a pusher driving device 31 formed by a cylinder arranged on the frame 1, and a pusher block 32 connected to the pusher drive device 31 placed in the feed passage 2;

[0040] The ends of a set of feeding channels 2 are respectively provided with feeding mechanisms 4;

[0041] Feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com