Surface rust removal device for assembly plate of illumination power distribution cabinet

A technology for power distribution cabinets and panels, applied in the field of rust removal devices on the surface of assembled panels, can solve the problem of poor overall rust removal effect of assembled panels, uncontrollable time for pickling and rust removal, poor panel rust removal effect, etc. problems, to achieve the effect of improving the rust removal effect, ensuring the rust removal effect, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

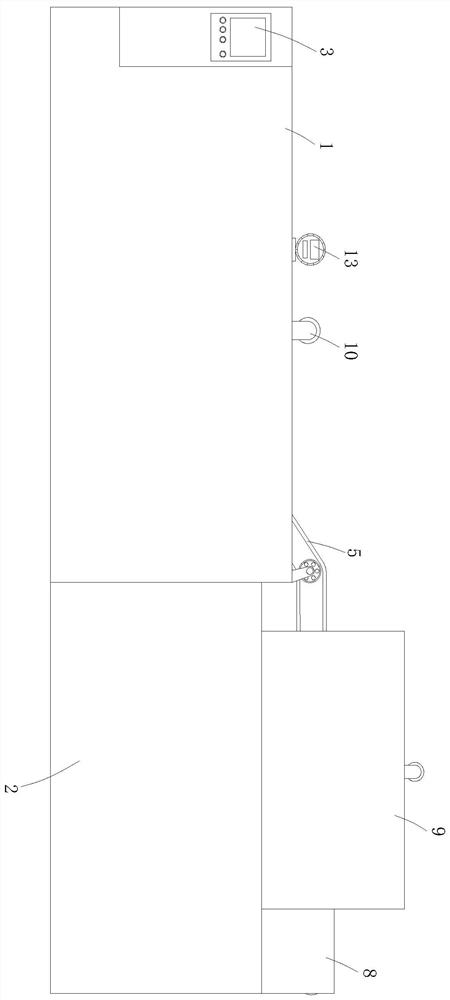

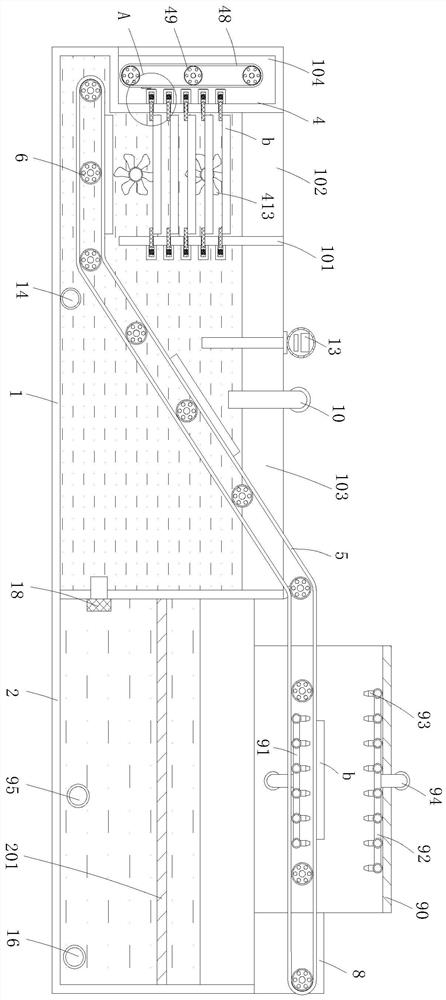

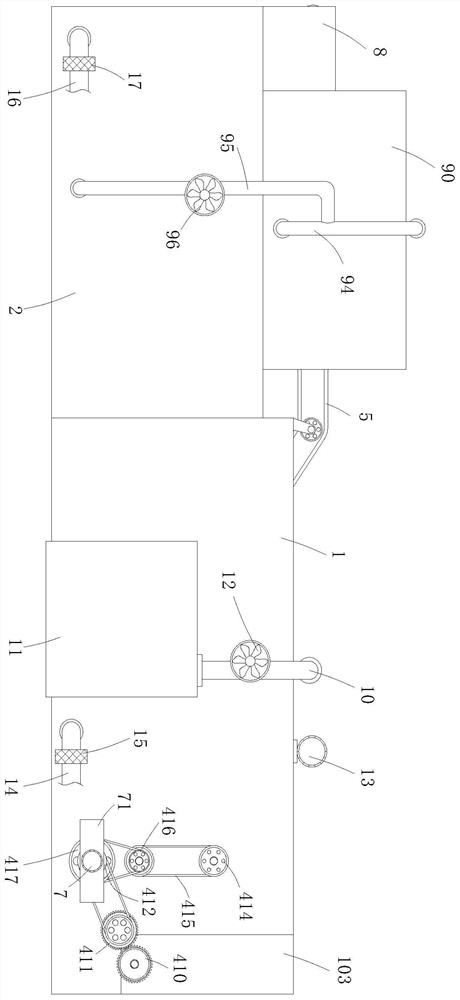

[0034] A surface derusting device for assembly panels of lighting distribution cabinets, comprising a pickling pool 1 and a flushing return pool 2 arranged adjacently. For the pickling of workpiece b, cleaning water is filled in the flushing backflow pool 2, and a flushing mechanism 9 is provided at the upper end of the flushing backflow pool 2, and a partition 101 is vertically installed in the inner cavity of the pickling pool 1, and the partition The plate 101 divides the pickling pool 1 into a pickling chamber 102 and a pool liquid chamber 103, and the pickling chamber 102 is provided with a derusting mechanism 4, and the side of the pickling pool 1 facing away from the pool liquid chamber 103 is provided with an installation chamber 104, The pickling tank 1 is provided with a transmission mesh belt 5 for outputting the plate workpiece b, and the transmission mesh belt 5 includes a lower horizontal section at the lower part of the inner cavity of the pickling chamber 102 an...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that, as figure 2 and 3 As shown, the lower part of the rear wall of the pickling tank 1 is connected with a pre-embedded drain pipe 14, and the embedded drain pipe 14 is provided with a drain valve 15 for discharging waste liquid after pickling in the pickling tank 1. The upper end of the pickling pool 1 corresponding to the position of the pool liquid chamber 103 is inserted with a feeding pipe 10, and the input end of the feeding pipe 10 is connected with a material box 11, and the material box 11 contains industrial hydrochloric acid with a concentration of 36% to 38%. %, and the feeding pipe 10 is provided with a material pump 12, the material pump 12 is started, and the high-concentration hydrochloric acid in the material box 11 is input into the pickling tank 1 to supplement the concentration of hydrochloric acid or cooperate with the water source to clean the preparation of hydrochloric acid to ensure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com