A kind of sponge city ceramic permeable brick prepared by mixing planets and its preparation method

A sponge city and permeable brick technology, applied in the field of building materials, can solve the problems of unstable water permeability of permeable bricks, easy agglomeration, uneven mixing of aggregates and auxiliary materials, etc., so as to avoid delamination and improve stability. performance, and the effect of solving production process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a kind of preparation method of the sponge city ceramic permeable brick prepared by popstar type mixing, comprising the following steps:

[0050] Crushing steps:

[0051] The waste ceramsite is obtained by pulverizing collected waste polished bricks, and the waste ceramsite is divided into three types according to the particle size: large, medium and small; the river sand and burnt gemstones are pulverized for use;

[0052] Ingredients steps:

[0053] Weigh waste ceramsite, river sand, burnt gems, pore forming agent, binder, flux, kaolin, glaze, water according to the formula quantity;

[0054] Mixing steps:

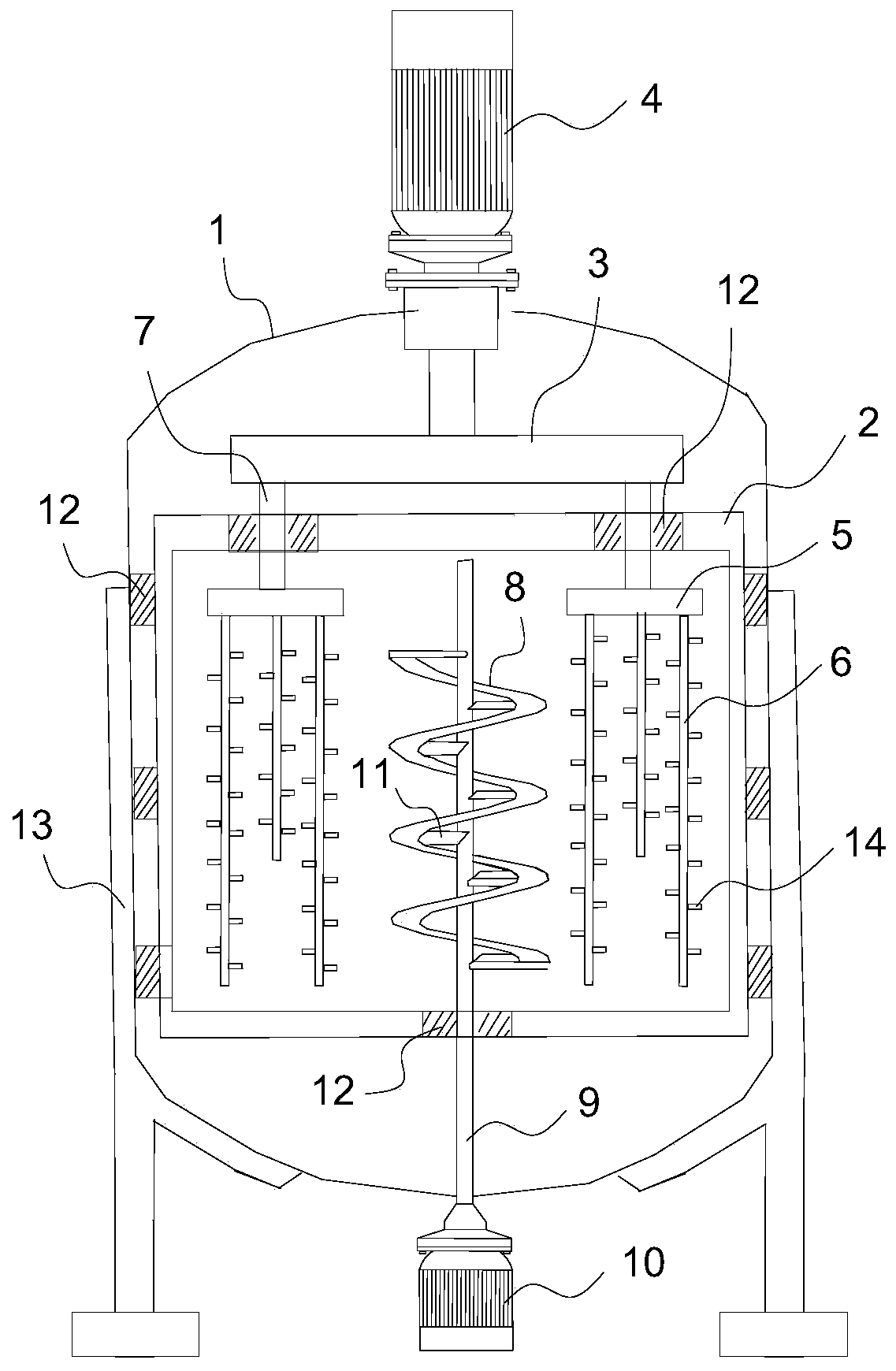

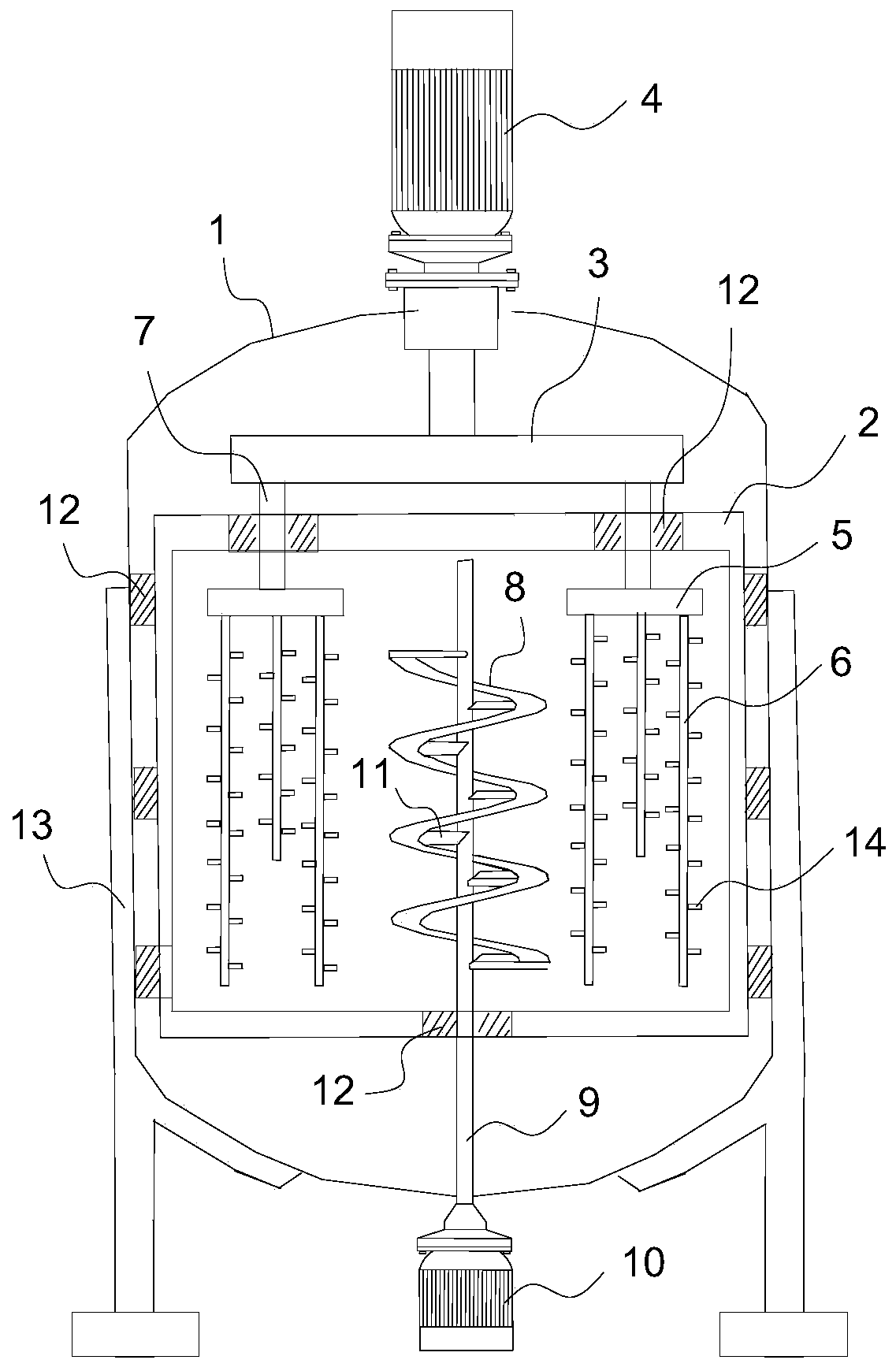

[0055] Pour waste ceramsite, river sand, and burnt gemstones into the mixing device of the popular star-type ceramic permeable brick raw materials for mixing. After stirring and mixing for 0.5 hours, pour in pore-forming agent, binder, flux, and kaolin respectively. , glaze, and water continue to stir and mix for 1-2 hours to...

Embodiment 1

[0076] A sponge city ceramic permeable brick prepared by mixing the pop star, which is made by firing the following components by weight: 100 parts of waste ceramsite, 7 parts of river sand, 6 parts of burnt gemstones, and 5.5 parts of pore-forming agent , 6 parts of binder, 4 parts of flux, 8 parts of kaolin, 2 parts of glaze, 3 parts of water.

[0077] The waste ceramsite is divided into large, medium and small ceramsite according to particle size, wherein the particle size of large ceramsite is 3.3-6.5mm, the particle size of medium ceramsite is 1-2.5mm, and the particle size of small ceramsite is 1-2.5mm. The particle size is 0.5-1 mm; the mass ratio of the three types of ceramsite, large, medium and small, is 5:4:1. The particle size of the river sand and burnt gems are both 3-6mm.

[0078] The pore forming agent is a mixture of chaff husk and wheat straw, and the mass ratio of the chaff husk to wheat straw is 1:4.

[0079] The binder is a mixture containing 10%-15% quart...

Embodiment 2

[0097] The difference from Example 1 is that the component content of the sponge city ceramic permeable brick is different, and it is made by firing the following components in parts by weight: 100 parts of waste ceramsite, 5 parts of river sand, 5 parts of burnt gemstone, pore-forming 5 parts of agent, 5 parts of binder, 2 parts of flux, 6 parts of kaolin, 1 part of glaze, and 2 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com