Laser cutting placket machine

A laser cutting and placket machine technology, applied in laser welding equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of high cost and complicated control, and achieve the effect of low cost, optimized working environment and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

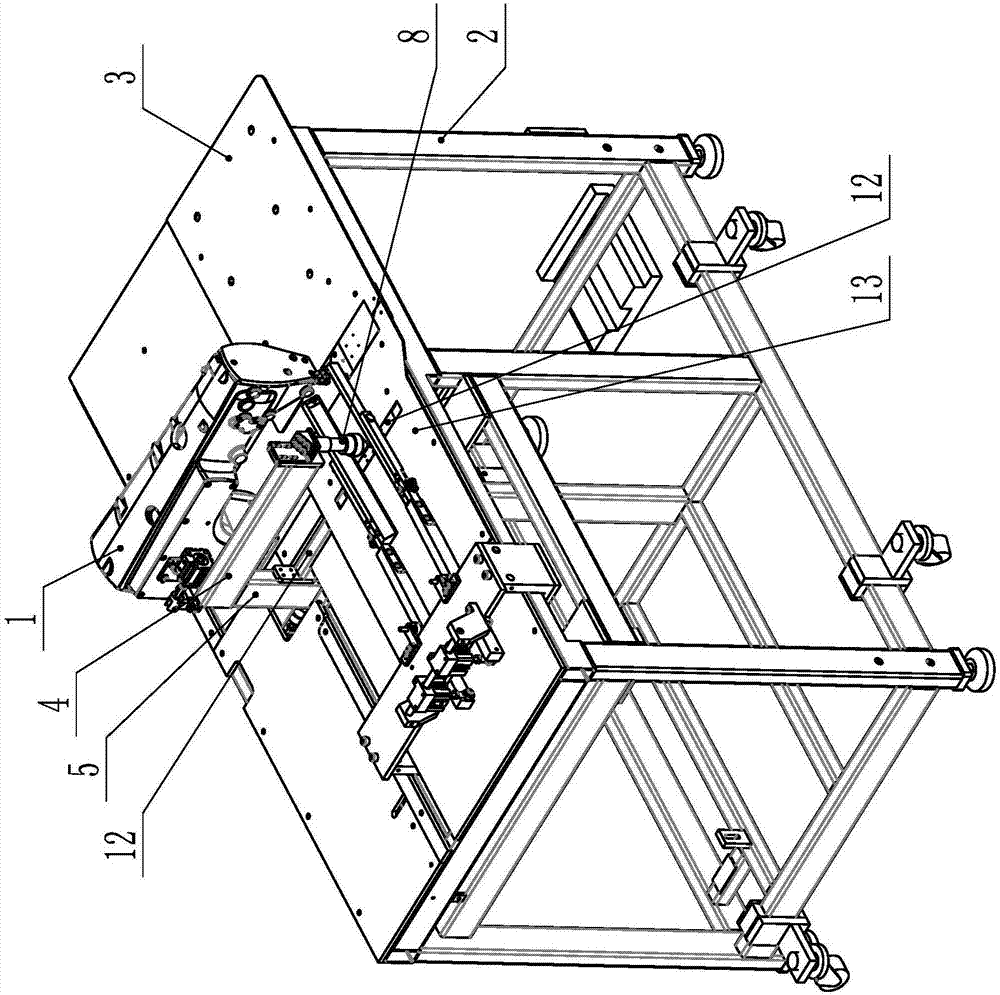

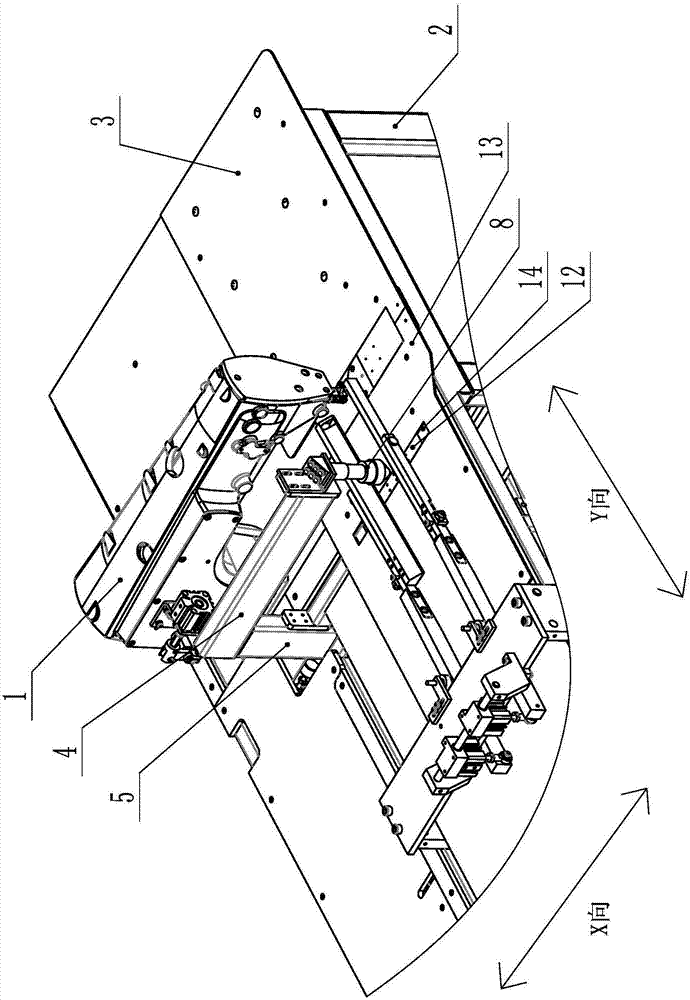

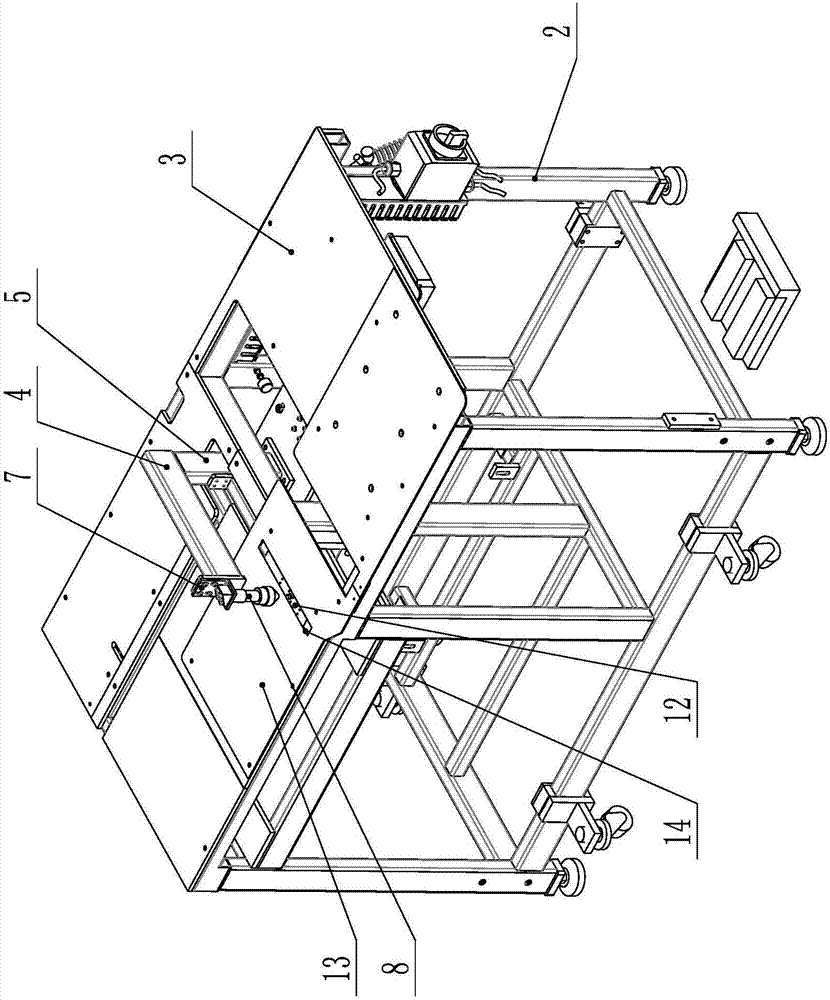

[0035] The present invention will be further described below with specific embodiment, see figure 1 -11:

[0036] A laser cutting placket machine, comprising a sewing machine head 1, a frame 2, a platen 3, a presser foot part capable of pressing the cloth and driving the cloth to move left and right, and a laser part for cutting the cloth. Be used for placing cloth on the platen 3. The sewing head 1 and the laser component are arranged on the same transmission component, and the transmission component drives the sewing head 1 and the laser component to move back and forth. The forward and backward movement in this embodiment is X-direction movement, and the left-right movement is Y-direction movement. The transmission components are arranged on the frame 1 . In the present invention, the sewing machine head 1 and the laser component are driven and moved by the same transmission component, which greatly simplifies the control mode, and the control is simpler and the cost is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com