Soft damage resistance testing method

A test method and performance technology, applied in the field of anti-soft injury performance test, can solve the problems of small test area, difficult to obtain damage medium, and inability to carry out more dimensional evaluation, and achieve the effect of simple operation and simple equipment maintenance.

Active Publication Date: 2017-11-07

NIPPON PAINT CHINA

View PDF12 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] First, the damage medium for testing is not easy to obtain, and needs to be customized according to the specified specifications;

[0005] Second, the test area is small and cannot be evaluated in more dimensions;

[0006] Third, it is impossible to provide test evaluation of soft injury performance;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

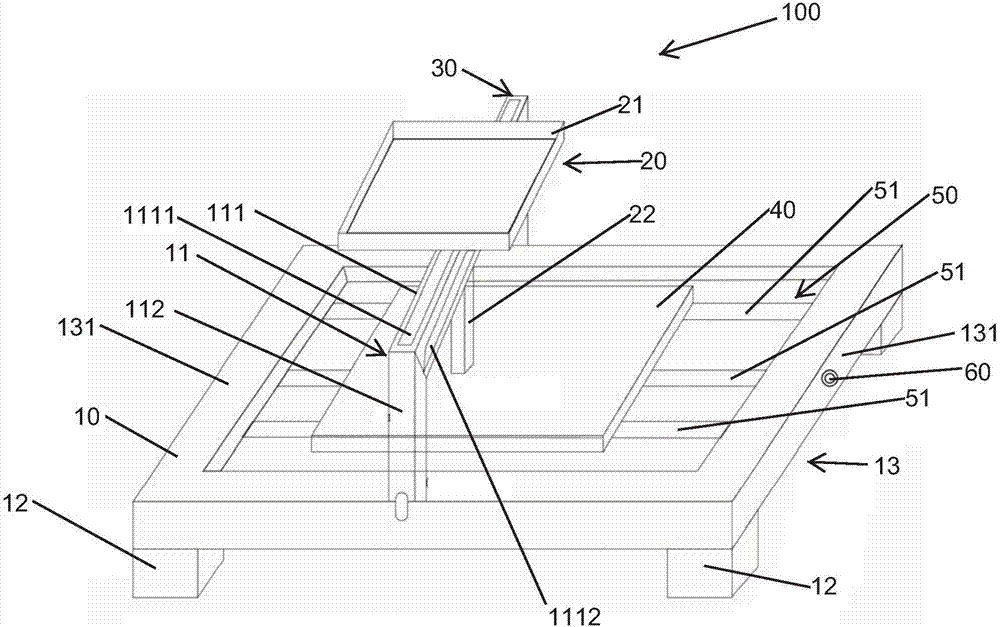

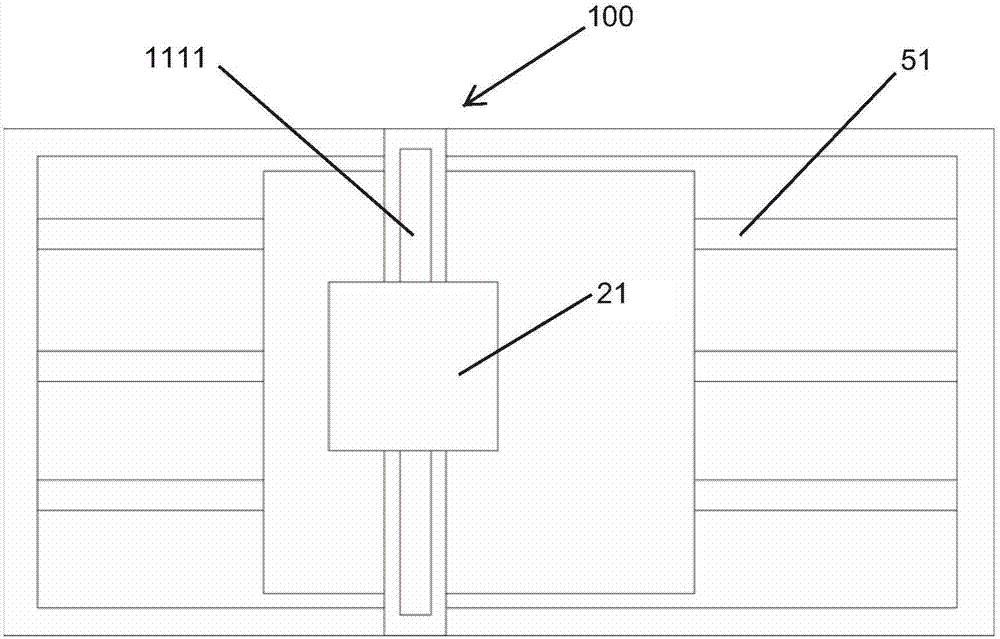

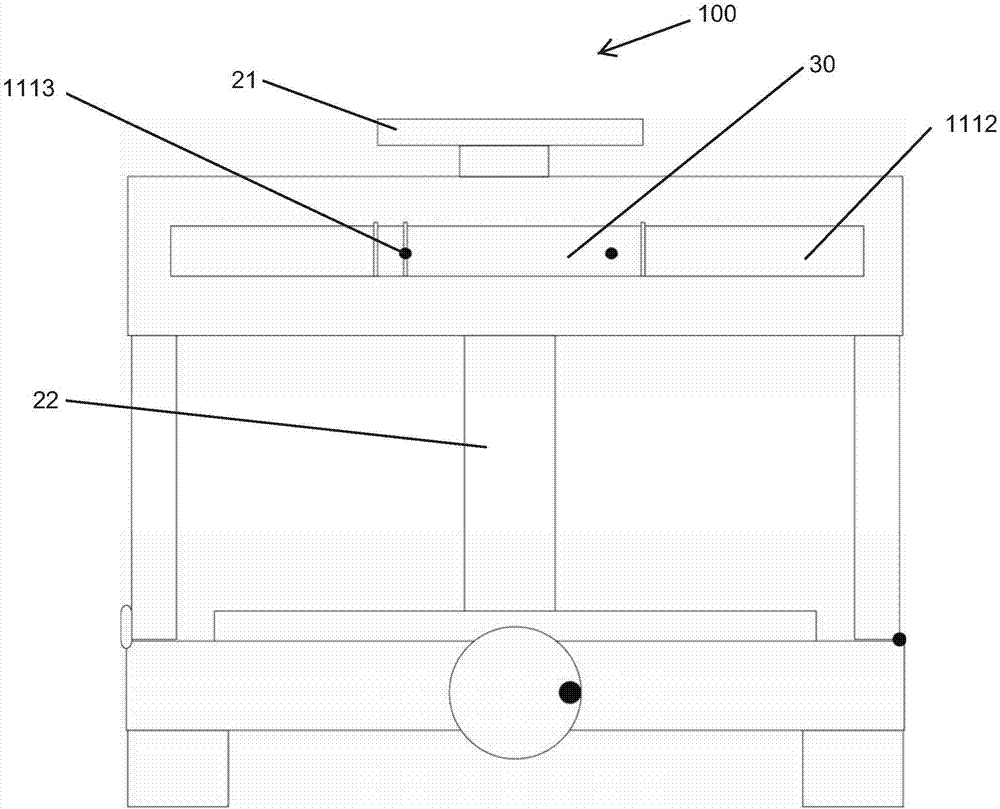

The invention discloses a soft damage resistance testing method. The soft damage resistance testing method comprises: testing the initial luster of a to-be-tested area of a to-be-tested piece; putting the to-be-tested piece on a sample base plate, and fixing the to-be-tested piece; driving the sample base plate to move the to-be-tested piece to one end of a base through a driving device; fixing a soft damage medium on a lower surface of a load device; moving a load positioning device to the to-be-tested area of the to-be-tested piece, and fixing the load positioning device; installing the load device on the base, and making the soft damage medium come into contact with the to-be-tested piece; driving the sample base plate to move relative to the load device through the driving device; driving the sample base plate to return to an initial position by the same way through the driving device; testing the endpoint luster of a rubbed area of the to-be-tested piece; evaluating the mechanical property of a material through the endpoint luster and the initial luster. The method is simple and convenient in operation, a complicated sample pretreatment requirement is avoided, testing medium varieties are easily replaced, the test area is large, and the method is suitable for qualitative and quantitative characterization.

Description

technical field [0001] The invention relates to the field of manufacture and application of surface coating materials for wooden floors, wooden furniture and other wooden products, in particular to a method for testing the anti-soft damage performance. Background technique [0002] During the actual use of wood coatings, it is inevitable that they will be worn to varying degrees, causing damage or loss of gloss to the paint film, which affects the appearance and use effect of the paint film and shortens the usable time of the paint film. Therefore, when developing wood coatings, relevant instruments and equipment are needed to evaluate the performance to ensure that the product has certain durability and application performance. [0003] At present, the test device for testing the damage of the paint film of wood coatings through abrasion is the Taber abrasion meter, which rubs a local area of the paint film through a contact end with a certain load, and qualitatively eval...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/56G01N3/02

CPCG01N3/02G01N3/56G01N2203/0282

Inventor 龙世喆高建东

Owner NIPPON PAINT CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com