High-frequency multi-layer circuit board hole conduction technology and high-frequency multi-layer circuit board using it

A multi-layer circuit and inner-layer circuit technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, etc., can solve the problems of high cost, easy peeling of hole copper, complicated process, etc., and achieve high product yield and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

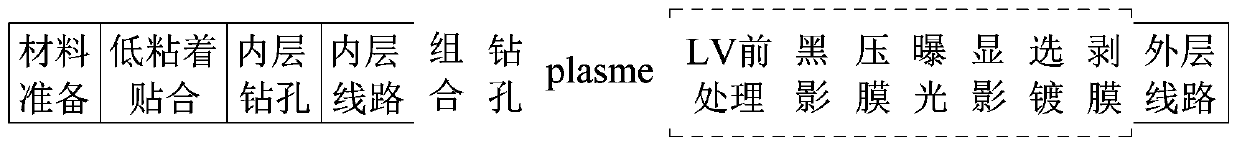

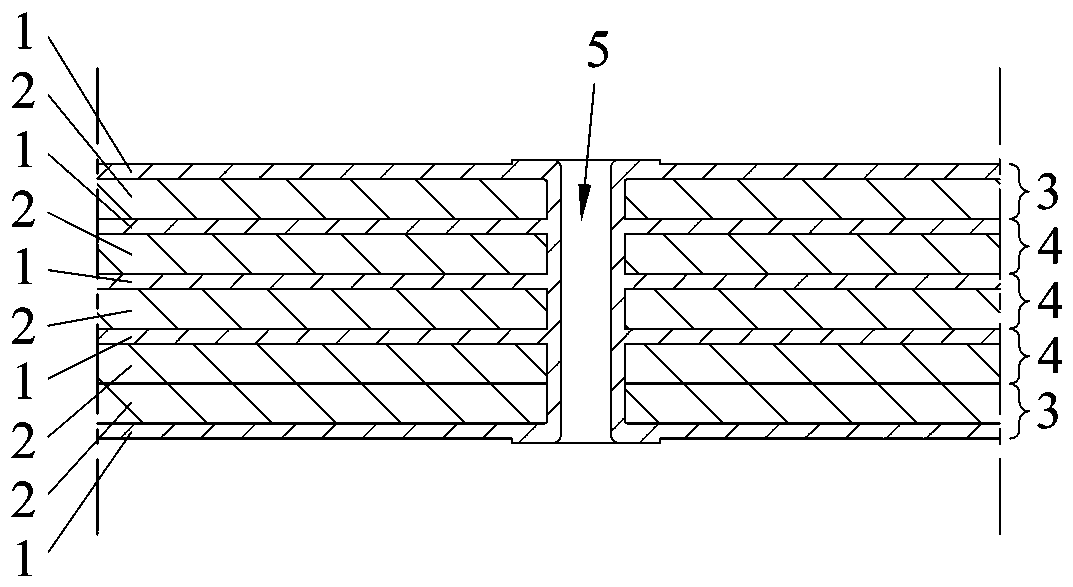

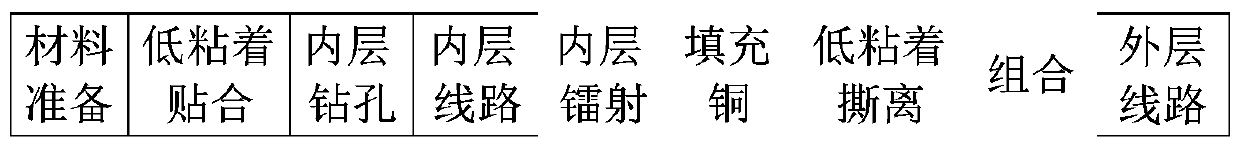

[0031] Example 1: As attached image 3 And Figure 4 As shown, a high-frequency multilayer circuit board hole conduction process for making a high-frequency multilayer circuit board with internal conduction via holes 7 includes the following steps:

[0032] 1. Prepare several inner single-layer boards 4 and two outer single-layer boards 3

[0033] (1) Material preparation, that is, copper foil distribution: prepare the copper foil composed of the base layer 2 and the copper layer 1 on one side of the base layer 2;

[0034] (2) Low-adhesion lamination: lamination of the low-adhesion layer on the other side surface of the base layer 2;

[0035] (3) Inner layer drilling: set positioning holes 6 through the low adhesion layer, base layer 2 and copper layer 1;

[0036] Through the above steps, the prototype of the outer single layer board 3 or the inner single layer board 4 can be obtained. For the inner single-layer board 4, continue to obtain through the following steps:

[0037] (4) Fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com