Multi-functional cement block processing technology

A processing technology and multi-functional technology, applied in the field of multi-functional cement block processing technology, can solve the problems of low processing efficiency, large volume of hollow blocks, small amount of mortar, etc., and achieve enhanced impact resistance and crack resistance flexibility , Excellent slump performance, good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

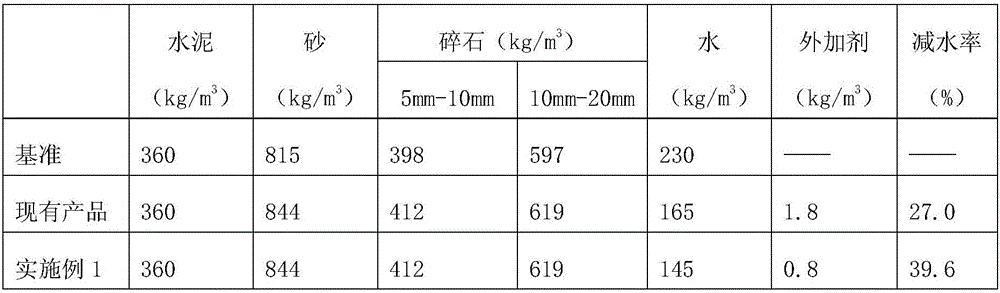

Embodiment 1

[0032] The processing technology of the multifunctional cement block is as follows:

[0033] a. Prepare materials according to the following weight ratio: 9 parts of gravel crushed material, 1 part of cement, 0.01 part of polypropylene fiber, and 2 parts of vitrified microbead particles;

[0034] The crushed sand and gravel are mixed with natural sand and waste concrete at a weight ratio of 1:2, and then crushed by a jaw crusher, iron-removed by a strong magnetic field, and finely crushed by a roller crusher until the particle size is 0.03 to 0.05 cm;

[0035] Described polypropylene fiber is the chopped fiber of length 8-10mm;

[0036] b. Add sand and gravel, cement, polypropylene fiber, and vitrified microbeads into the mixer, add 170-180kg of water per cubic solid material and stir for 10 minutes. Add slow-release polycarboxylate water reducer to the stirring, the amount of water reducer is 1kg / m 3 .

[0037] c. Add the stirred slurry into the pressure molding machine fo...

Embodiment 2

[0041] The processing technology of the multifunctional cement block is as follows:

[0042] a. Prepare materials according to the following weight ratio: 10 parts of gravel crushed material, 1 part of cement, 0.02 part of polypropylene fiber, and 1 part of vitrified microbead particles;

[0043] The crushed sand and gravel are mixed with natural sand and waste concrete in a weight ratio of 1:1, and then crushed by a jaw crusher, iron-removed by a strong magnetic field, and finely crushed by a roller crusher until the particle size is 0.03-0.05 cm;

[0044] Described polypropylene fiber is the chopped fiber of length 8-10mm;

[0045] b. Add sand and gravel, cement, polypropylene fiber, and vitrified microbeads to the mixer, add 170-180kg of water per cubic solid material and stir for 8 minutes. Add slow-release polycarboxylate water reducer to the stirring, the amount of water reducer is 0.8kg / m 3 .

[0046] c. Add the stirred slurry into the pressure molding machine for vi...

Embodiment 3

[0050] The processing technology of the multifunctional cement block is as follows:

[0051] a. Prepare materials according to the following weight ratio: 12 parts of gravel aggregate, 1 part of cement, 0.02 part of polypropylene fiber, and 1.5 parts of vitrified microbead particles;

[0052] The crushed sand and gravel is natural sand crushed by jaw crusher, strong magnetic iron removal, and finely crushed by roller crusher to a particle size of 0.03-0.05 cm;

[0053] Described polypropylene fiber is the chopped fiber of length 8-10mm;

[0054] b. Add sand and gravel, cement, polypropylene fiber, and vitrified microbeads into the mixer, add 170-180kg of water per cubic solid material and stir for 5 minutes. Add slow-release polycarboxylate water reducer to the stirring, the amount of water reducer is 1.0kg / m 3 .

[0055]c. Add the stirred slurry into the pressure molding machine for vibration and pressure molding, and the molding set pressure is 6MPa;

[0056] d. After fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com