A kind of nearly α-type titanium alloy and its preparation method

A forming method and titanium alloy technology, applied in the field of titanium alloy processing, can solve the problems of high cost, long process and only elongation, and achieve the effects of low cost, simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

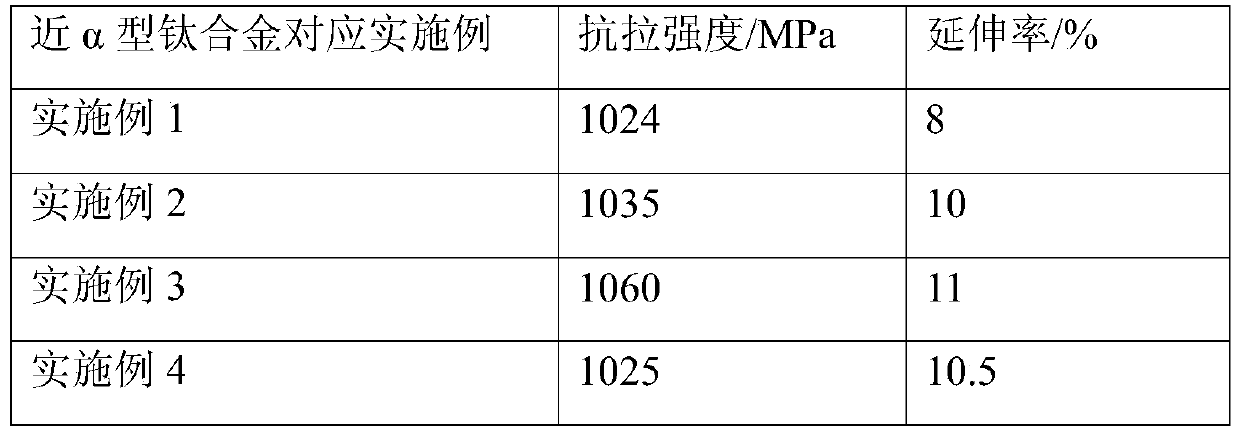

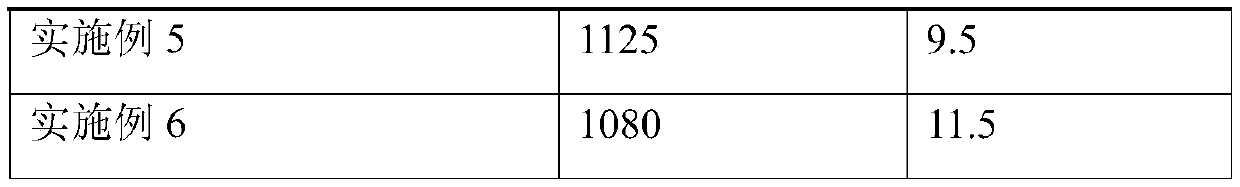

Examples

Embodiment 1

[0031] A method for preparing and forming a near-alpha-type titanium alloy is carried out in the following steps:

[0032] Step 1: powder metallurgy billet

[0033] Weigh the raw material powder according to the composition and mass percentage of near α-type titanium alloy. The specific composition and mass percentage are: 5.0% for Al, 2.0% for Sn, 3.5% for Zr, 0.3% for Mo, and 0.4% for Si. Y is 0.1%, and the balance is Ti;

[0034] Put the raw material powder with a particle size of 300 mesh into the mixing tank, place the mixing tank in the powder mixing machine and mix the powder for 8 hours to obtain the mixed powder, put the mixed powder into the rubber sheath and cold isostatic press molding, the molding pressure 150MPa, holding time 300s, to obtain the blank formed by cold isostatic pressing;

[0035] Put the billet formed by cold isostatic pressing into a vacuum sintering furnace for sintering, raise the temperature to 1100°C for 2 hours, and cool down with the furna...

Embodiment 2

[0042] A method for preparing and forming a near-alpha-type titanium alloy is carried out in the following steps:

[0043] Step 1: powder metallurgy billet

[0044] Weigh the raw material powder according to the composition and mass percentage of near-α-type titanium alloy. The specific composition and mass percentage are: 5.6% for Al, 2.2% for Sn, 3.5% for Zr, 0.4% for Mo, and 0.3% for Si. Y is 0.15%, and the balance is Ti;

[0045] Put the raw material powder with a particle size of 400 mesh into a mixing tank, place the mixing tank in a powder mixing machine, and mix the powder for 10 hours to obtain a mixed powder, put the mixed powder into a rubber sheath, and then cold isostatically press to form it. The pressure is 180MPa, and the holding time is 320s to obtain the blank formed by cold isostatic pressing;

[0046] Put the billet formed by cold isostatic pressing into a vacuum sintering furnace for sintering, raise the temperature to 1200°C for 3 hours, and cool down w...

Embodiment 3

[0053] A method for preparing and forming a near-alpha-type titanium alloy is carried out in the following steps:

[0054] Step 1: powder metallurgy billet

[0055] Weigh the raw material powder according to the composition and mass percentage of near-α-type titanium alloy. The specific composition and mass percentage are: 6.0% for Al, 2.3% for Sn, 4% for Zr, 0.5% for Mo, and 0.6% for Si. Y is 0.2%, and the balance is Ti;

[0056]Put the raw material powder with a particle size of 200 mesh into a mixing tank, place the mixing tank in a powder mixing machine, and mix the powder for 12 hours to obtain a mixed powder, put the mixed powder into a rubber sheath, and then cold isostatically press to form it. The pressure is 200MPa, and the holding time is 340s to obtain the blank formed by cold isostatic pressing;

[0057] Put the billet formed by cold isostatic pressing into a vacuum sintering furnace for sintering, raise the temperature to 1300°C for 3.5 hours, and cool with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com