Electrolytic deep purification and sulfuric acid recovery method of radioactive waste resin Fenton oxidation waste liquid

A technology of radioactive waste resin and radioactive waste liquid, applied in radioactive purification, nuclear engineering, etc., can solve the problems of large amount of secondary waste and many process links, and achieve the effect of low cost, simple process and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

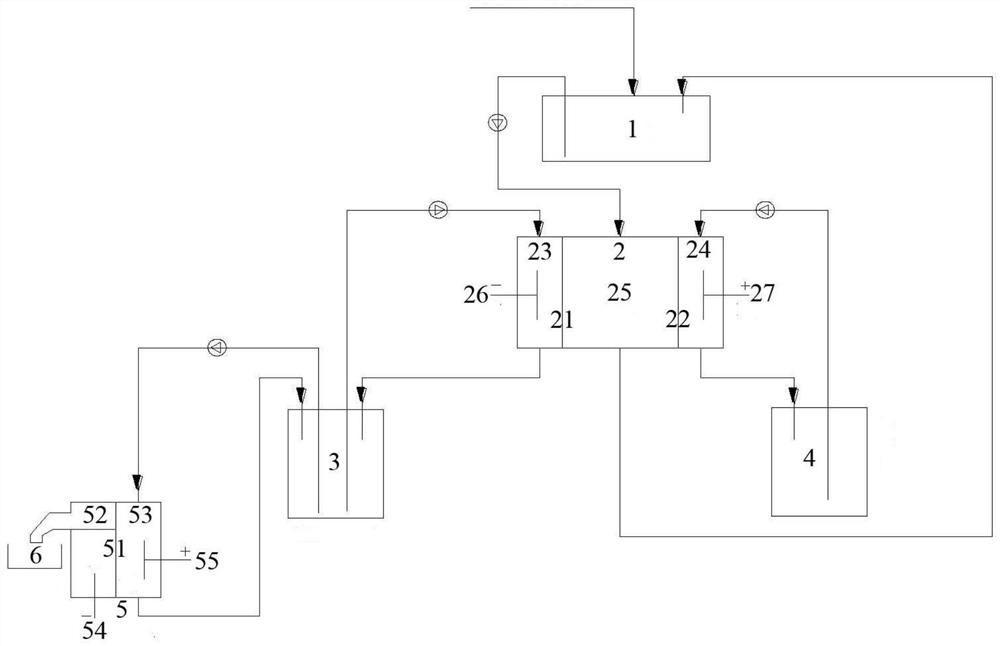

[0031] The exemplary operation principle of the radioactive waste resin Fenton oxidation waste liquid electrolytic deep purification and sulfuric acid recovery method of the present invention is as follows: figure 1 As shown, the method includes the following steps.

[0032] (1) The radioactive waste resin Fenton oxidation waste liquid stored in the radioactive waste liquid storage tank 1 is sent to the electrolytic cell 2 for electrolysis. The electrolytic cell 2 is divided into the electrolytic cell cathode chamber 23 on both sides, the electrolytic cell anode chamber 24 and the middle electrolytic cell middle section 25 by the electrolytic cell positive membrane 21 and the electrolytic cell negative membrane 22 therein. An electrolytic cell cathode 26 is provided in the electrolytic cell cathode chamber 23 to concentrate anions, and an electrolytic cell anode 27 is provided in the electrolytic cell anode chamber 24 to condense the anions. ions are concentrated. The elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com