Raw material smashing device for livestock feed manufacturing

A raw material pulverizing and pulverizing device technology, applied in feed, application, grain processing and other directions, can solve the problems of low pulverization efficiency, complicated operation, complex structure, etc., and achieve the effect of improving pulverization efficiency, simple operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

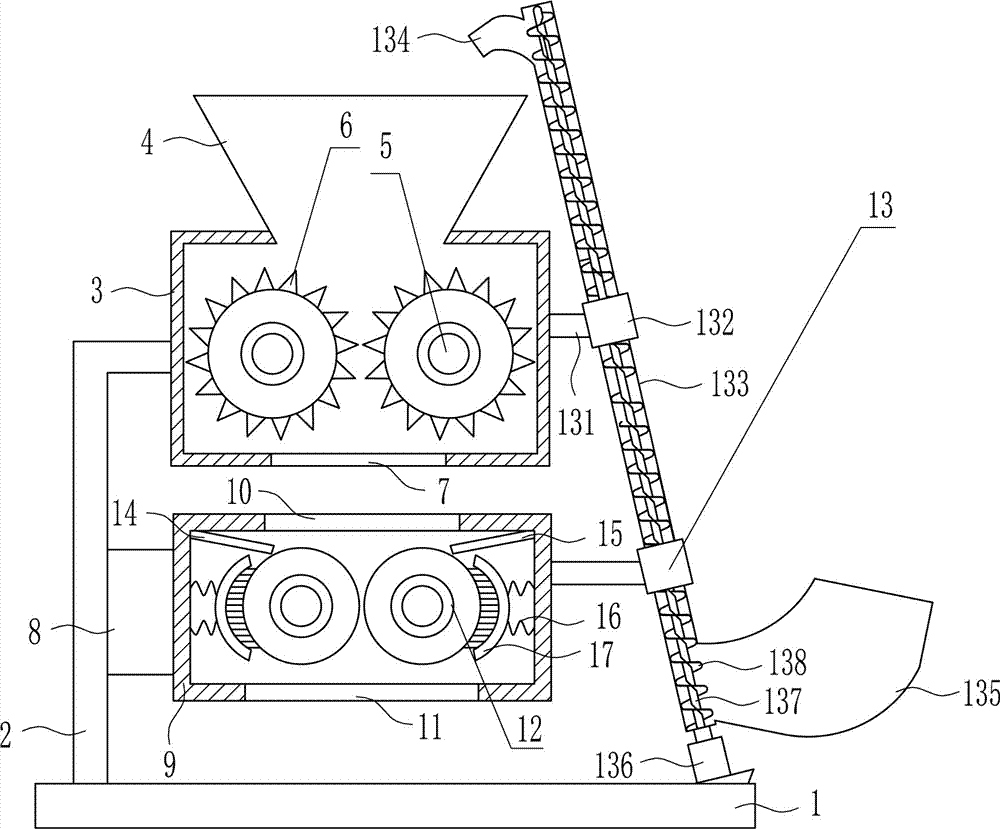

[0037] A raw material crushing device for animal feed, such as Figure 1-7 As shown, it includes a base plate 1, a 7-shaped plate 2, a box body 3, a lower hopper 4, a driving device 5 and a crushing device 6, the left side of the top of the base plate 1 is provided with a 7-shaped plate 2, and the right end of the 7-shaped plate 2 is passed through a bolt The way of connection is connected with a box body 3, the top of the box body 3 is equipped with a lower hopper 4, the box body 3 is provided with a driving device 5, the box body 3 is equipped with a crushing device 6, and the middle of the bottom of the box body 3 is opened. Mouth 7.

Embodiment 2

[0039] A raw material crushing device for animal feed, such as Figure 1-7 As shown, it includes a base plate 1, a 7-shaped plate 2, a box body 3, a lower hopper 4, a driving device 5 and a crushing device 6, the left side of the top of the base plate 1 is provided with a 7-shaped plate 2, and the right end of the 7-shaped plate 2 is passed through a bolt The way of connection is connected with a box body 3, the top of the box body 3 is equipped with a lower hopper 4, the box body 3 is provided with a driving device 5, the box body 3 is equipped with a crushing device 6, and the middle of the bottom of the box body 3 is opened. Mouth 7.

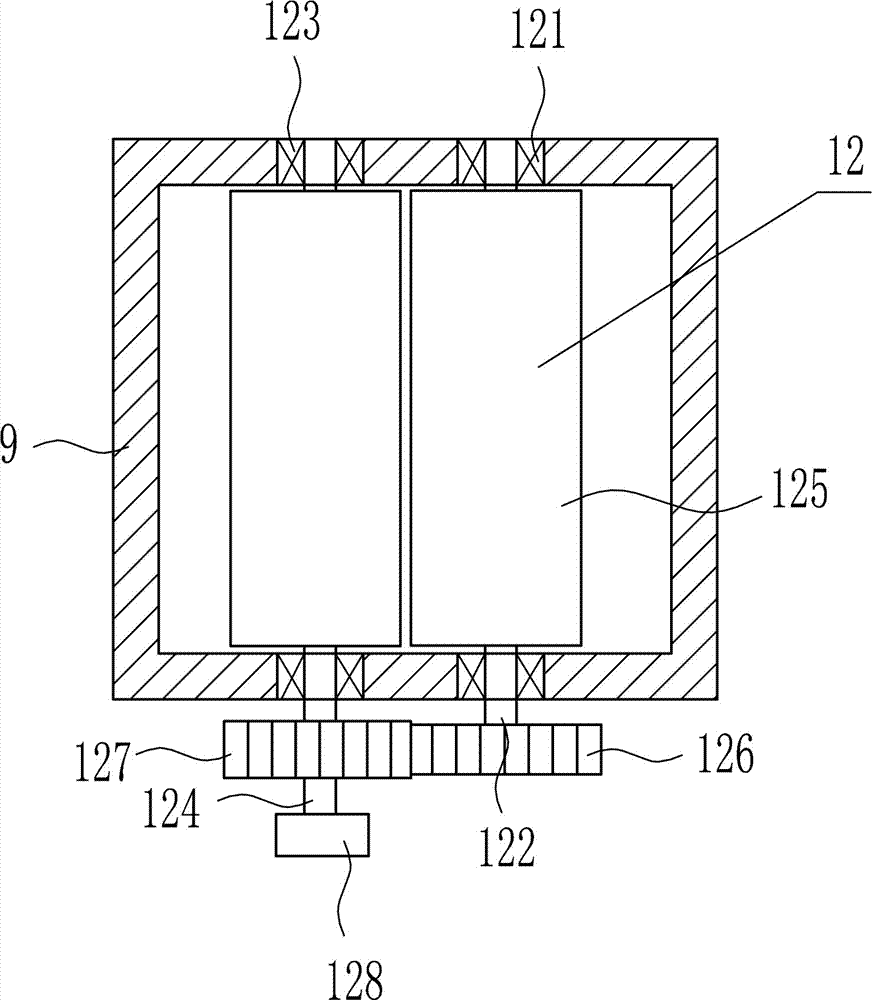

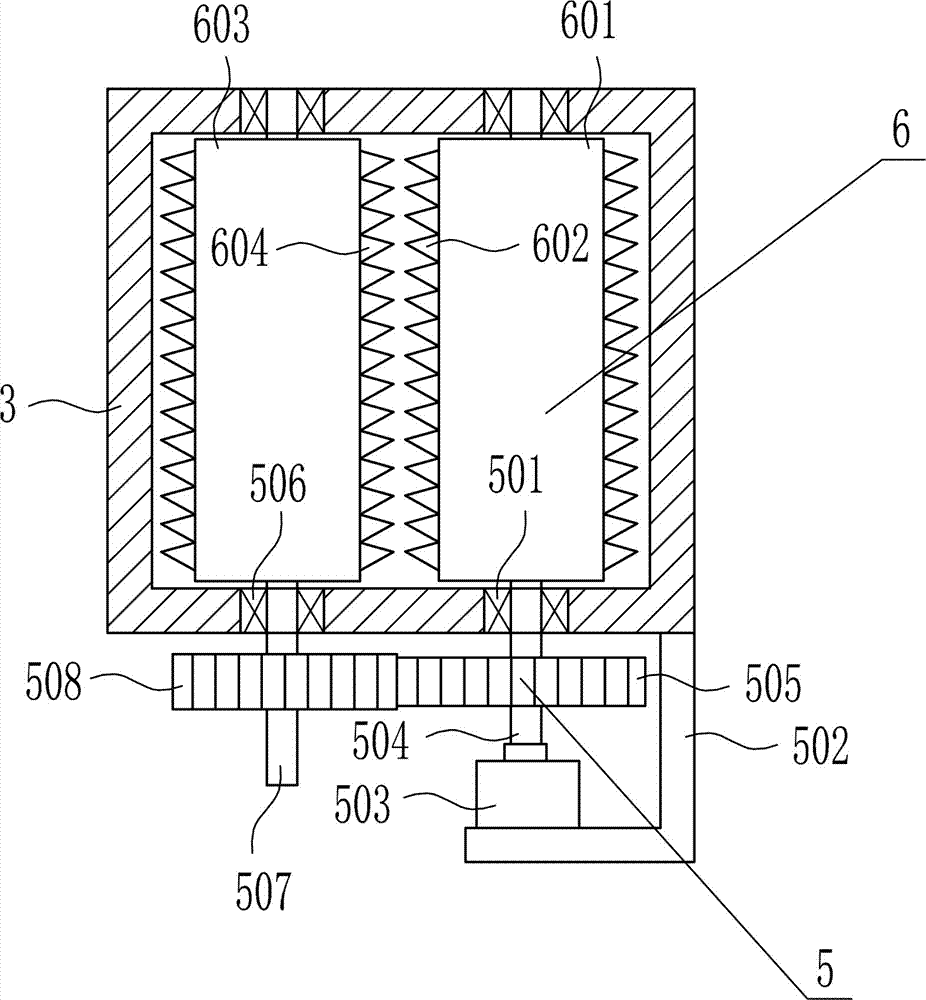

[0040] The driving device 5 includes a first bearing seat 501, an L-shaped plate 502, a first motor 503, a first rotating shaft 504, a first gear 505, a second bearing seat 506, a second rotating shaft 507 and a second gear 508, and the first bearing There are two seats 501, and the two first bearing seats 501 are respectively embedded and i...

Embodiment 3

[0042] A raw material crushing device for animal feed, such as Figure 1-7 As shown, it includes a base plate 1, a 7-shaped plate 2, a box body 3, a lower hopper 4, a driving device 5 and a crushing device 6, the left side of the top of the base plate 1 is provided with a 7-shaped plate 2, and the right end of the 7-shaped plate 2 is passed through a bolt The way of connection is connected with a box body 3, the top of the box body 3 is equipped with a lower hopper 4, the box body 3 is provided with a driving device 5, the box body 3 is equipped with a crushing device 6, and the middle of the bottom of the box body 3 is opened. Mouth 7.

[0043] The driving device 5 includes a first bearing seat 501, an L-shaped plate 502, a first motor 503, a first rotating shaft 504, a first gear 505, a second bearing seat 506, a second rotating shaft 507 and a second gear 508, and the first bearing There are two seats 501, and the two first bearing seats 501 are respectively embedded and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com