Ship laboratory cabin unit

A cabin unit and laboratory technology, which is applied in the field of naval laboratory cabin units, can solve the problems of easy bending and deformation of decorative panels, unsightly appearance, and inability to move positions, etc., to improve overall functionality, easy cleaning, and good vision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

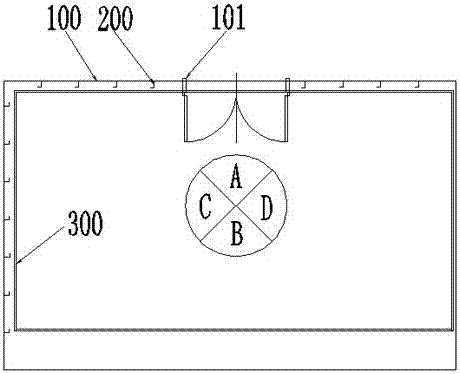

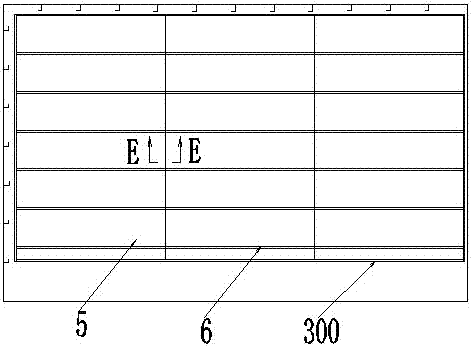

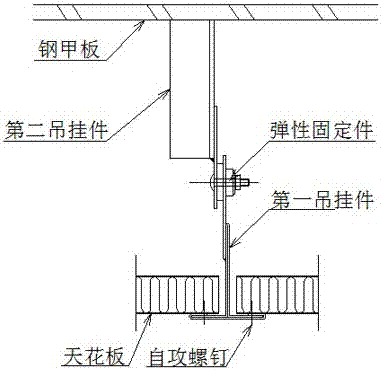

[0056] see Figure 1-Figure 14 , a kind of naval laboratory cabin unit that the present invention relates to, it comprises the cabin unit body, and the cabin unit body comprises steel surrounding wall 100, stiffener 200 and liner plate 300; There is a fire door 101, and a plurality of vertical track grooves 6 are arranged on the decorative panels on the rear wall 2, the left wall 3 and the right wall 4 of the cabin unit body, and the decorative panel of the ceiling 5 of the cabin unit body A plurality of longitudinal or transverse track grooves 6 are arranged on the ceiling, the ceiling is fixed on the first hanging piece above it by self-tapping screws, the first hanging piece is fixed on the second hanging piece above it through elastic fixing pieces, the second The hanger is connected to the steel deck above it. Wherein the outer side of track groove 6 on rear wall 2, left wall 3 and right wall 4 is also provided with horizontal adjusting groove 7, and eyebolt 8 and slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com