Elevator device

A technology of elevators and cars, applied in the field of elevator devices, can solve the problems of poor passenger comfort and achieve the effect of reducing fluid noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

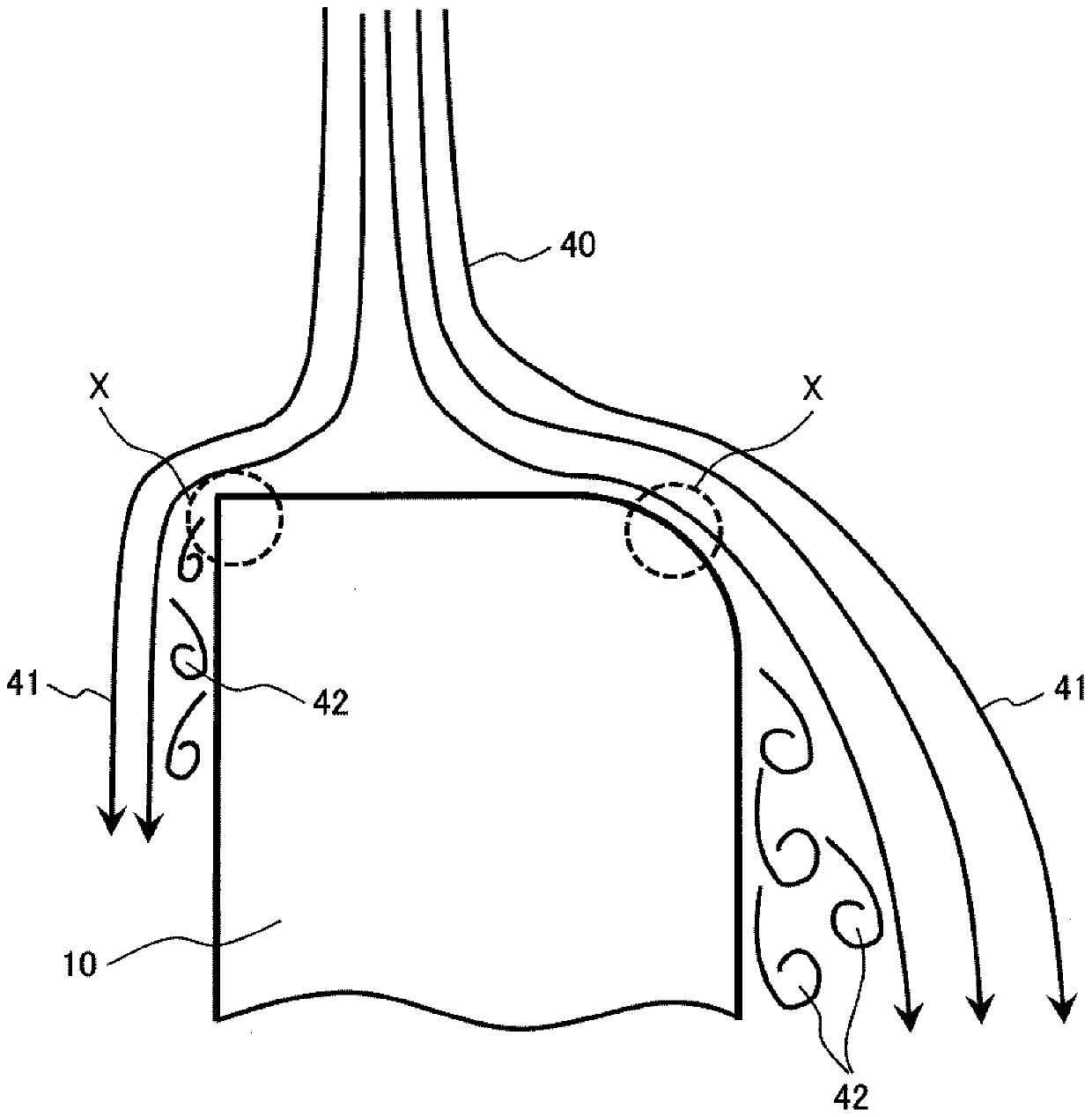

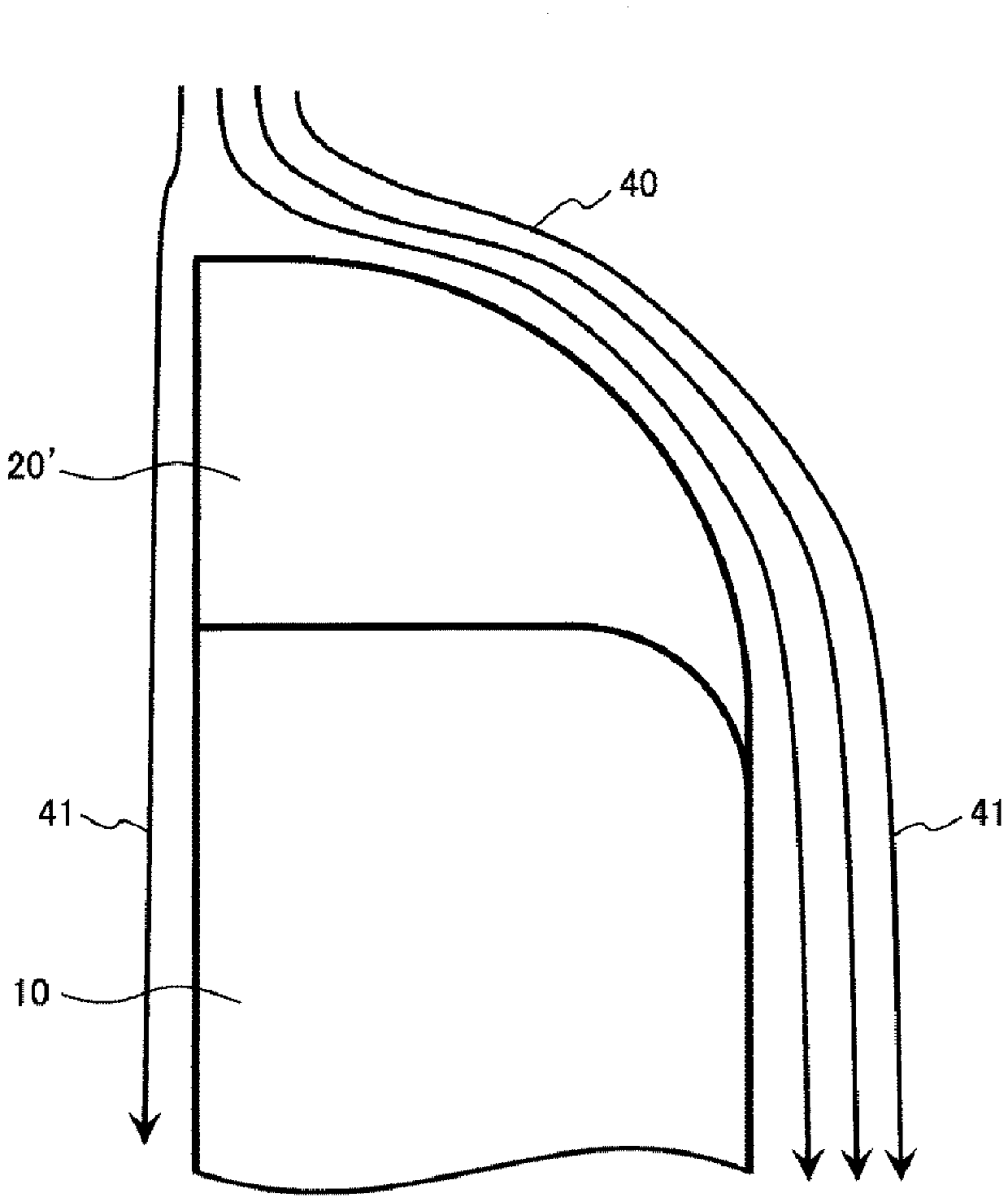

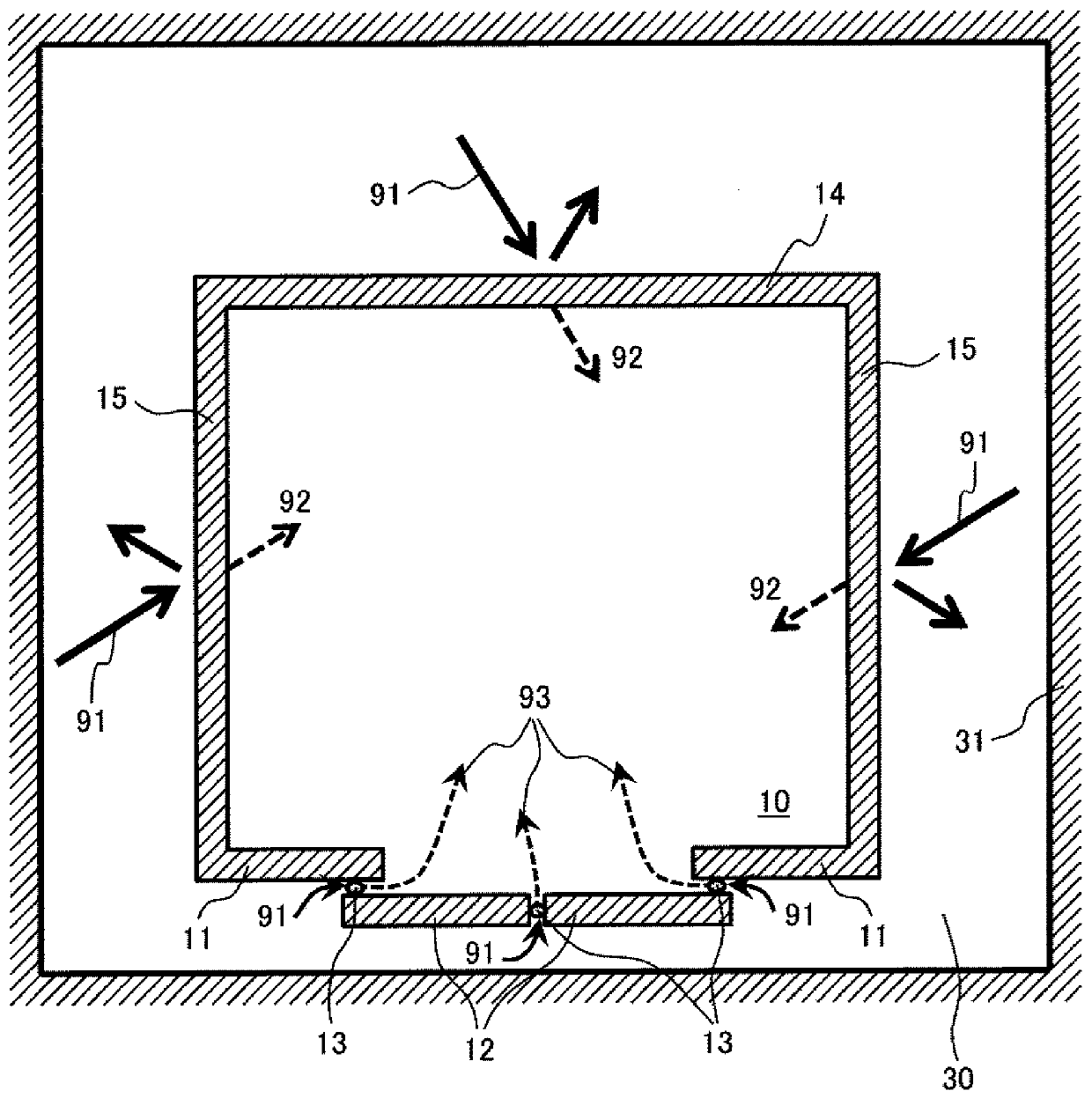

[0041] Figure 5 It is a figure which schematically shows the elevator apparatus of this invention. Such as Figure 5 As shown, the elevator device 100 of the present invention includes a car 10 that moves up and down in the hoistway 30, a counterweight 50 that lifts together with the car 10, a rope 51 that is connected to the car 10 at one end and connected to the counterweight 50 at the other end, A hoisting machine (not shown) having a sheave 52 around which a rope 51 is wound, and straightening structures 20 and 20 ′ provided on the car 10 . The rectifying structure 20 is installed on the upper part of the car 10, and the rectifying structure 20' is arranged on the lower part of the car 10. The car 10 is composed of a box similar to the above-mentioned conventional car, and the box has: a front surface provided with a door 12; a back surface opposite to the front surface; a pair of side surfaces provided between the front surface and the back surface; , the top surface ...

Embodiment 2

[0053] Figure 9 It is a perspective view schematically showing a car of an elevator apparatus according to Embodiment 2 of the present invention, Figure 10 is true Figure 9 A schematic view of the front panel viewed from the front. The difference between the rectifying structure 20b of this embodiment and the rectifying structure 20a of Embodiment 1 lies in the shape of the notch 23b. In Embodiment 1, the front end of the front panel 21a has a shape with two peaks on the left and right due to the notch 23a (this shape is referred to as "two peaks on the left and right"), while the front end of the front panel 21b of this embodiment is viewed from the front. , has the shape of a trapezoid cut out by the notch 23b. The front panel 21a of Embodiment 1 has many curved surface parts. For materials such as FRP, there are parts that must be molded. Since it can be manufactured with a metal plate etc., compared with the front panel 21a of Example 1, the front panel 21b can be m...

Embodiment 3

[0055] Figure 11 It is a perspective view schematically showing a car of an elevator apparatus according to Embodiment 3 of the present invention. The difference between the rectifying structure 20c of the present embodiment and the rectifying structure 20a of the first embodiment and the rectifying structure 20b of the second embodiment lies in the shape of the notch 23c. The notch 23c of the front panel 21c of this embodiment has a V shape when viewed from the front. Even with such a shape, the same effects as those of Examples 1 and 2 can be obtained. In addition, the shape of the notch is not limited to the shape of the above-mentioned embodiments 2 and 3, and may have other polygonal shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com