Low-temperature preheating system for engineering machine

A low-temperature technology for construction machinery, applied in the field of low-temperature preheating systems for construction machinery, can solve problems such as difficulty in the start-up process of construction machinery, drivers unable to get heating in time, and diesel prone to wax formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

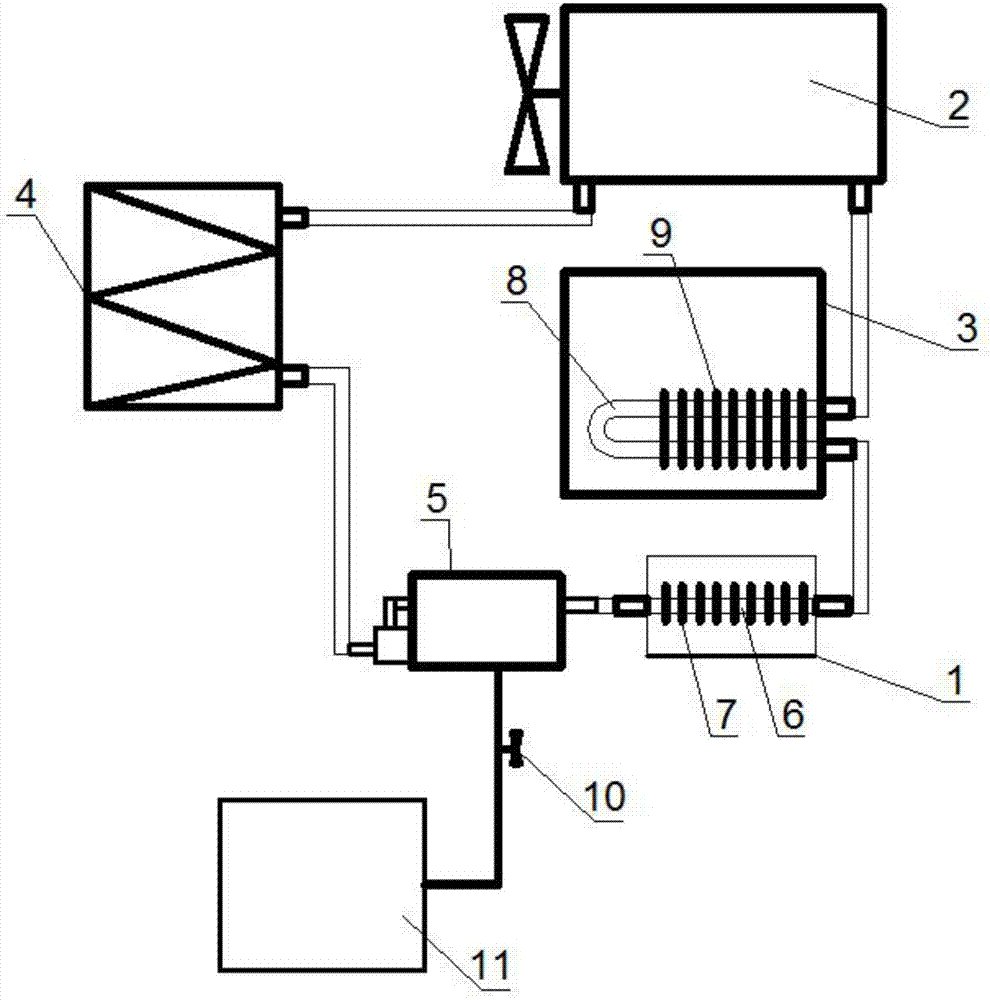

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, a low-temperature preheating system for engineering machinery includes an oil tank 1, an engine assembly 2, a diesel fuel tank 3, a warm air system 4 located in the cab, a fuel heater 5 and a gasoline oil tank 11, and the oil tank 1 The bottom is provided with the first heating pipeline 6 that runs through transversely, and the first heating pipeline 6 is provided with a plurality of cooling ribs 7 along its length direction, and the two ends of the first heating pipeline 6 pass through the sides of the oil tank 1 respectively. The left part and the right part are made of water inlet 1 and water outlet 1. The bottom of the diesel fuel tank 3 is provided with a U-shaped second heating pipeline 8, and the second heating pipeline 8 is provided with a plurality of radiators along its length direction. Fin 2 9, the two free ends of the second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com