A method of on-line weighing of molten iron in induction furnace based on distributed parameter model

A distributed parameter model, induction furnace technology, applied in electric furnaces, weighing equipment for materials with special properties/forms, iron and steel manufacturing processes, etc., can solve problems that are difficult to copy, increase the cost of measurement, and cannot achieve online weighing of molten iron To achieve the effect of simple hardware structure and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0058] In this embodiment, an intermediate frequency induction furnace with a melting rate of 40 t / h is selected for research.

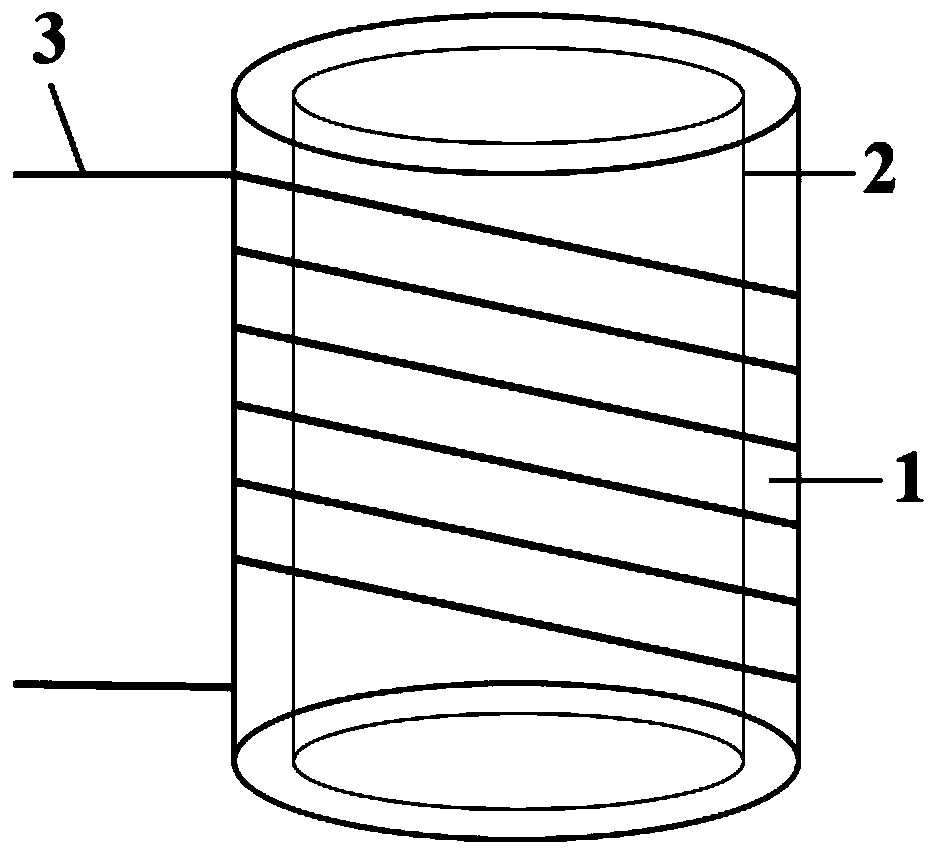

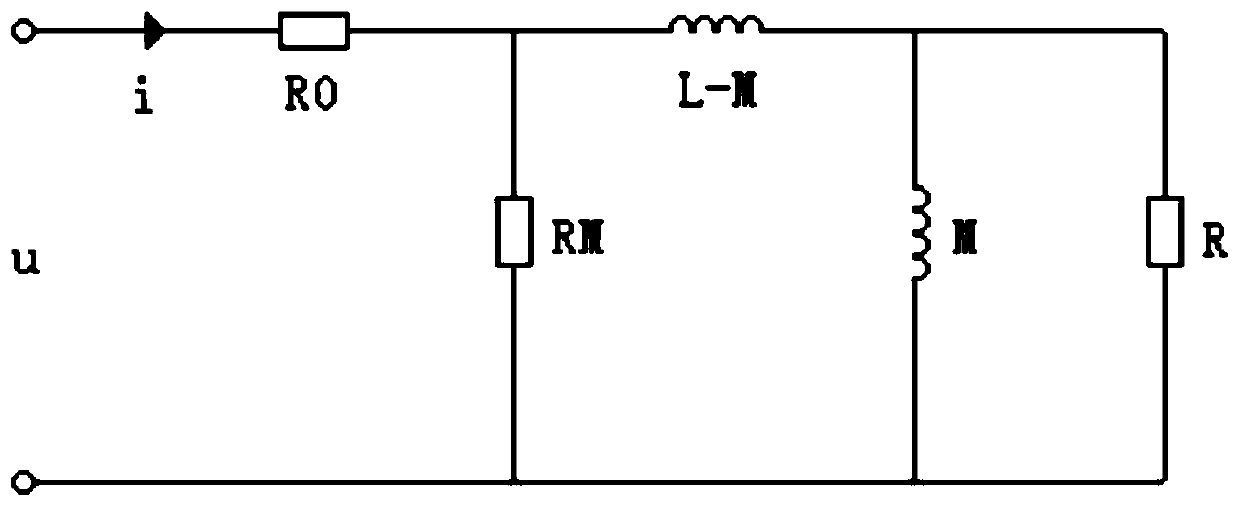

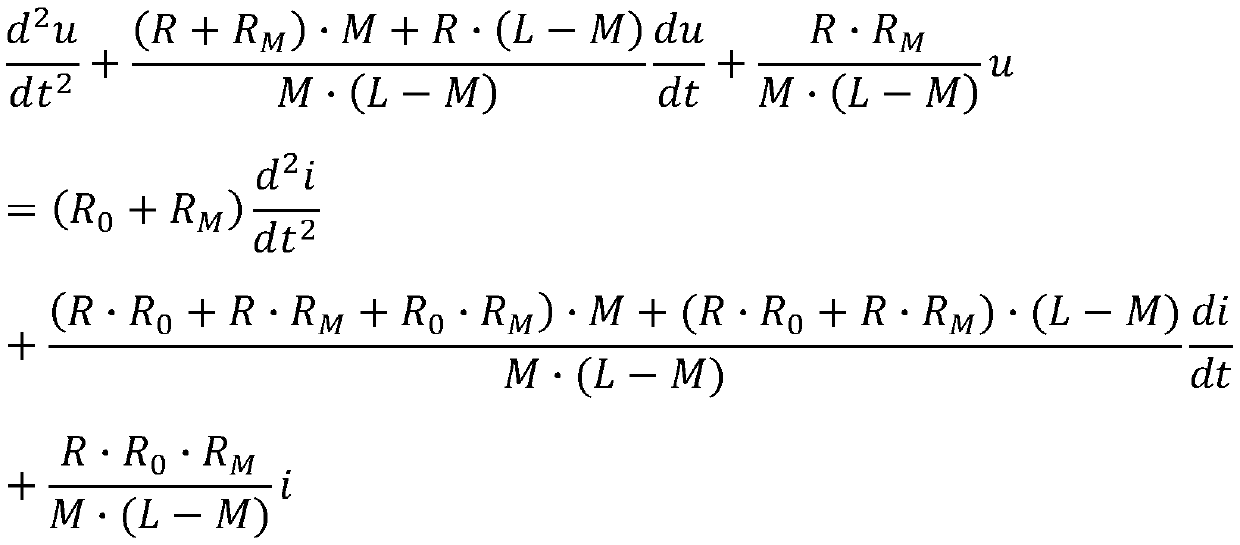

[0059] Such as figure 1 As shown, a magnetizer 1 is embedded in the furnace body of the intermediate frequency induction furnace, the inner wall of the furnace is coated with a furnace lining 2, and an induction coil 3 is wound outside the magnetizer. When there is scrap steel to be smelted in the furnace, the intermediate frequency power supply is connected, the induction coil 3 is energized, and a magnetic flux is generated in the induction furnace, a part of which passes through the scrap steel and molten iron, and the other part does not pass through, forming two inductances, namely mutual inductance M and leakage inductan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com