Multishaft motion control card based on RS-232 serial bus

A RS-232 and serial bus technology, applied in the field of multi-axis motion control cards, can solve the problems of unsatisfactory board cards, high cost, and poor acceleration and deceleration performance, and achieve low cost, high flexibility, and connection The effect of low pin count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

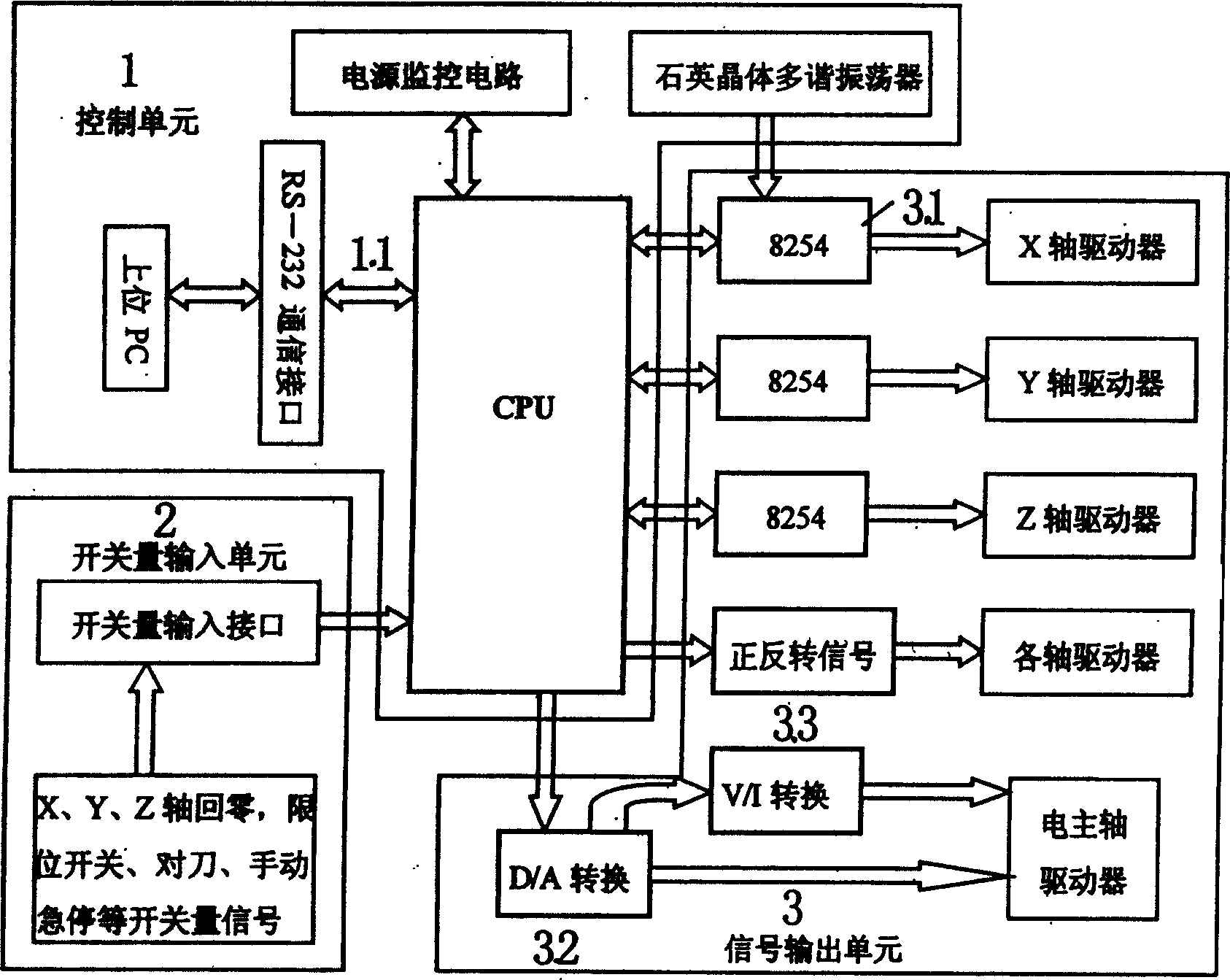

[0015] like figure 1 As shown, the present invention includes a control unit 1, a switch input unit 2 and a signal output unit 3; wherein:

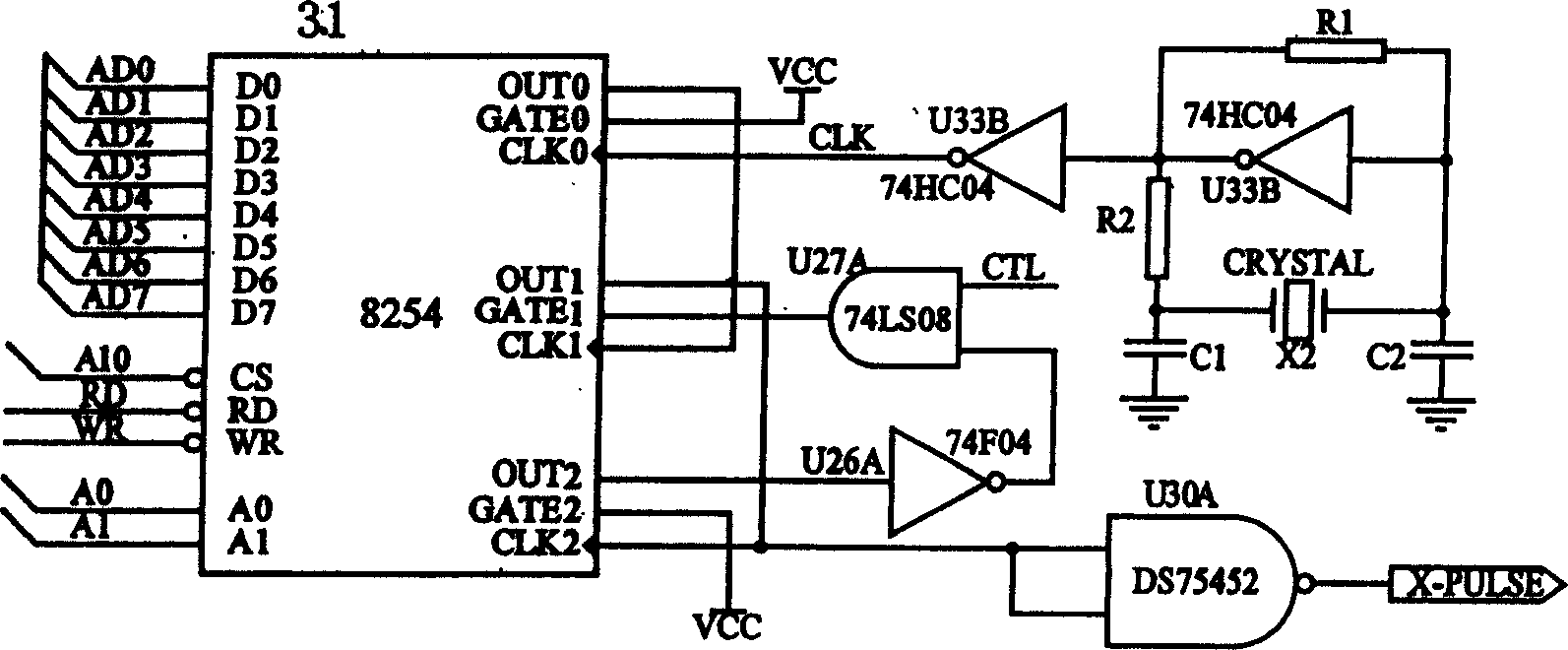

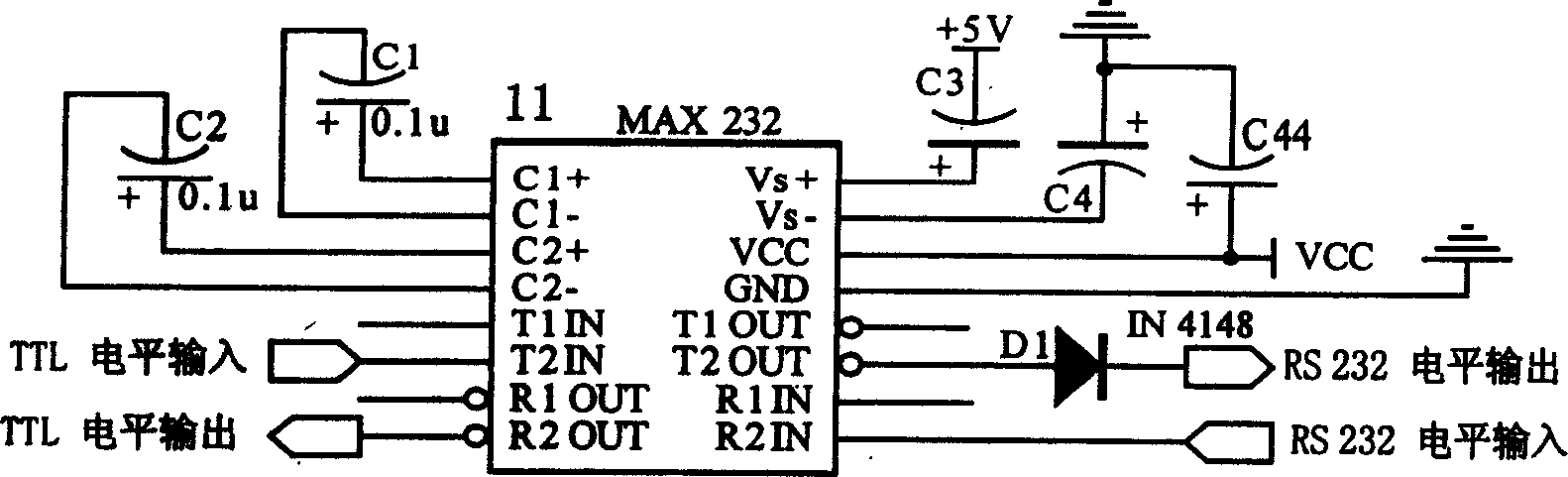

[0016] 1) Control unit 1: It includes RS-232 communication interface 1.1, quartz crystal multivibrator, and power monitoring circuit; one end of RS-232 communication interface 1.1 is connected to the single-chip CPU through a serial bus, and the other end is connected to the upper PC. The pulse signal generated by the crystal multivibrator is connected to the programmable counter / timer 8254, and the power monitoring circuit is connected to the single-chip CPU through the bus;

[0017] 2) Switch input unit 2: It includes a switch acquisition module, a switch signal isolation and shaping module; the switch acquisition module collects external X, Y, Z zero return, limit switch, and tool setting signal quantities through limit switches and photoelectric switches , the switch signal isolation and shaping module realizes the level conversion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com