Method for heating oil shale reservoir

A technology for shale reservoirs and heating oil, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of high temperature and high pressure gas injection and circulation that are not elaborated in detail, and achieve resource saving and recovery efficiency. High, maneuverable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

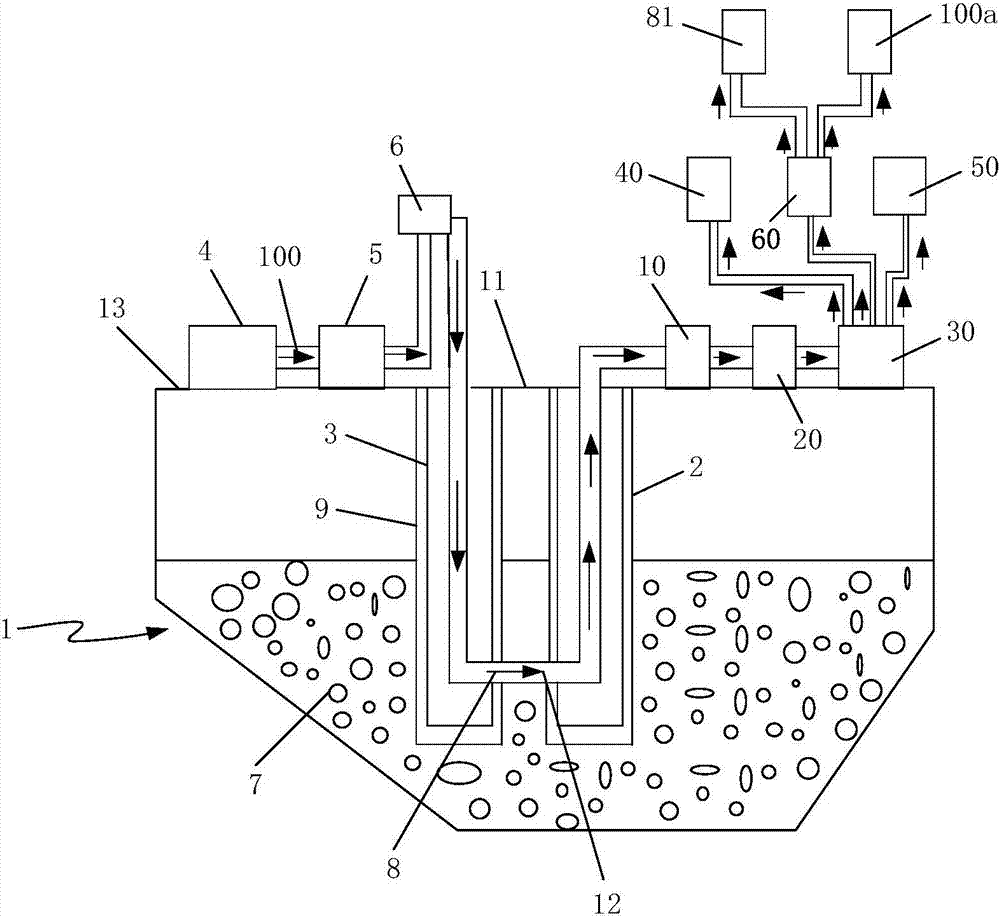

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] There is no record in the prior art on how to inject high-temperature and high-pressure gas into oil shale, and make the high-temperature and high-pressure gas returned to the ground continue to be recycled. Therefore, this application is aimed at this technical problem A method for heating oil shale reservoirs is presented. Next, the specific steps of the method will be described in detail.

[0025] The temperature range of the above-mentioned high-temperature and high-pressure gas is greater than or equal to 350 degrees and less than or equal to 500 degrees, and the range of the gas pressure of the high-temperature and high-pressure gas is greater than or equal to 2 MPa (megapascals) and less than or equal to 5 MPa (megapascals).

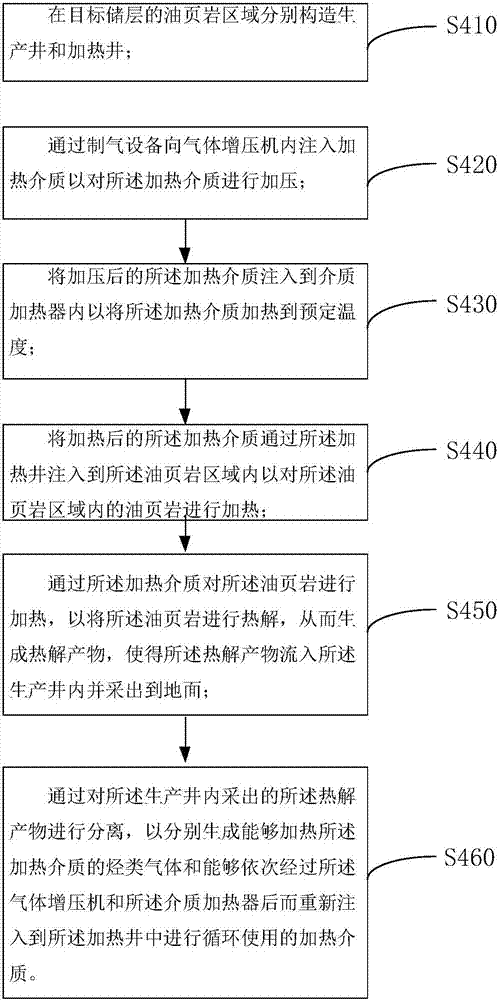

[0026] Such as figure 1 with figure 2 As shown, among them, figure 1 It is schematically shown that the method includes:

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com