Blocking method for blocking device at discharging port of melting furnace

A discharge port and melting furnace technology, which is applied in the field of non-ferrous metal smelting supporting equipment, can solve the problems of poor sealing, hidden dangers to the safety of operators, inconvenient operation, etc., and achieve the effect of firm sealing, convenient operation, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

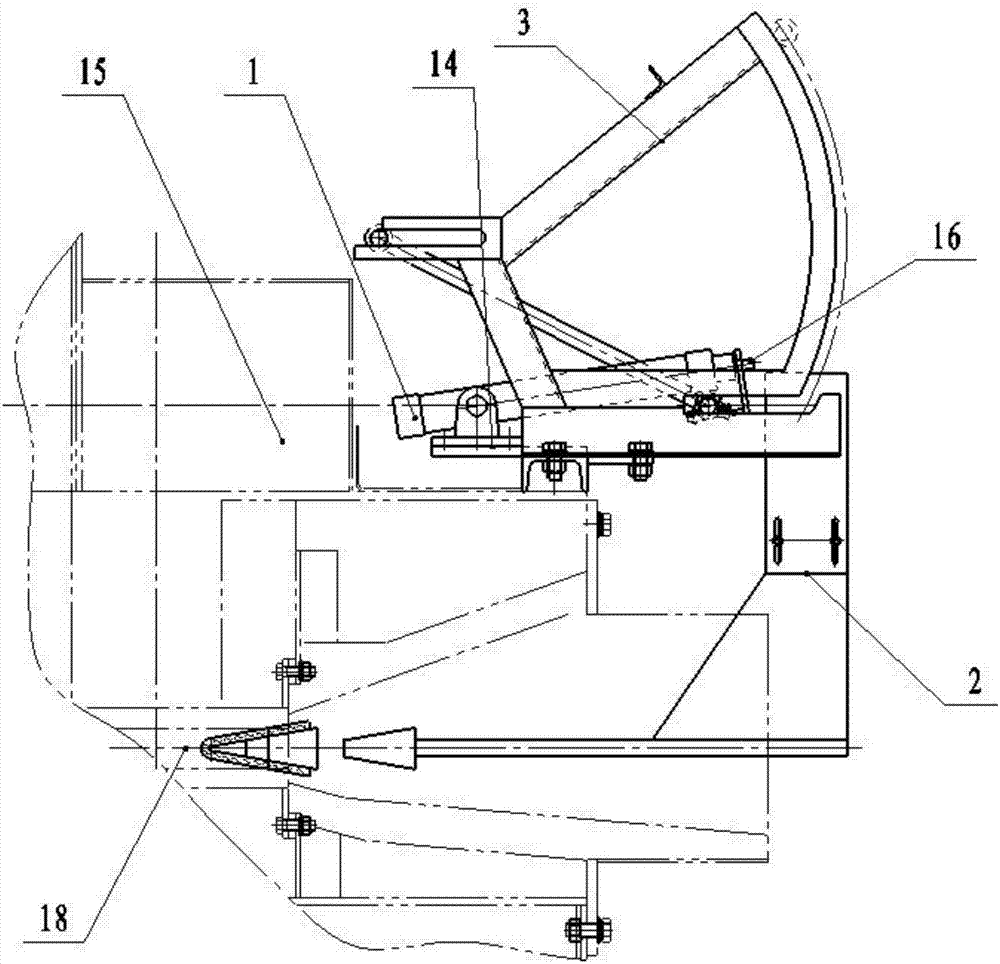

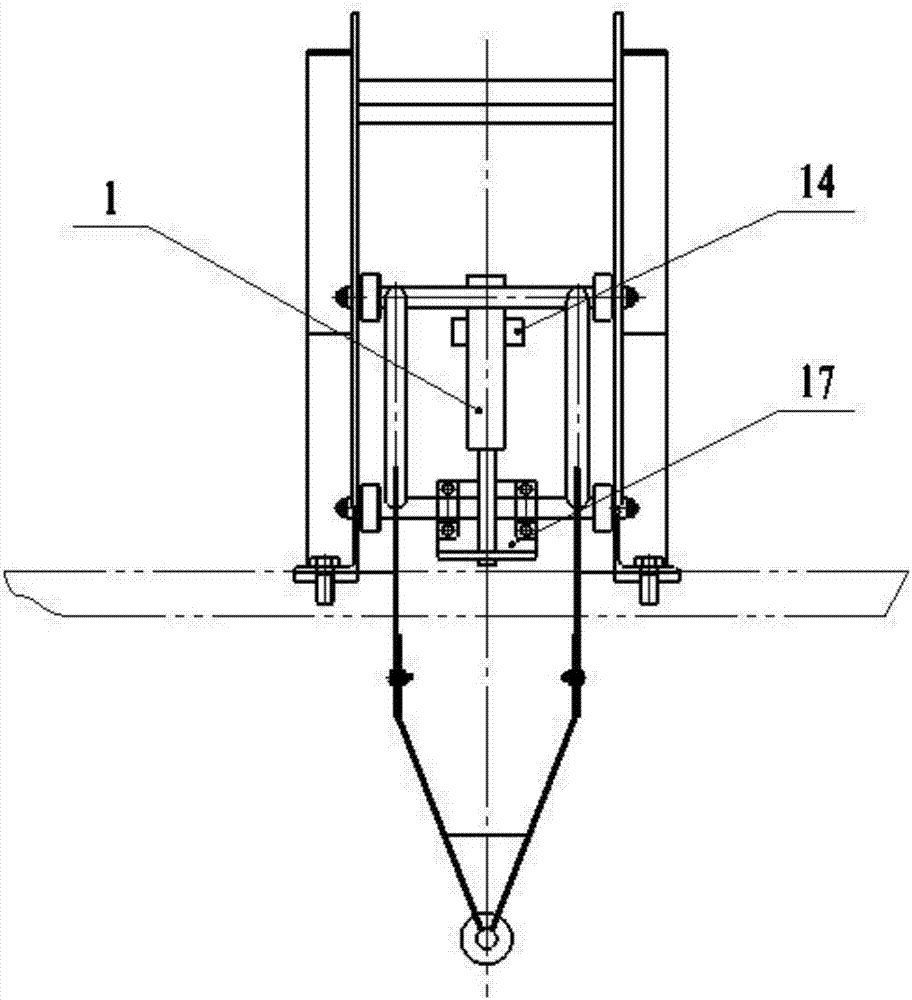

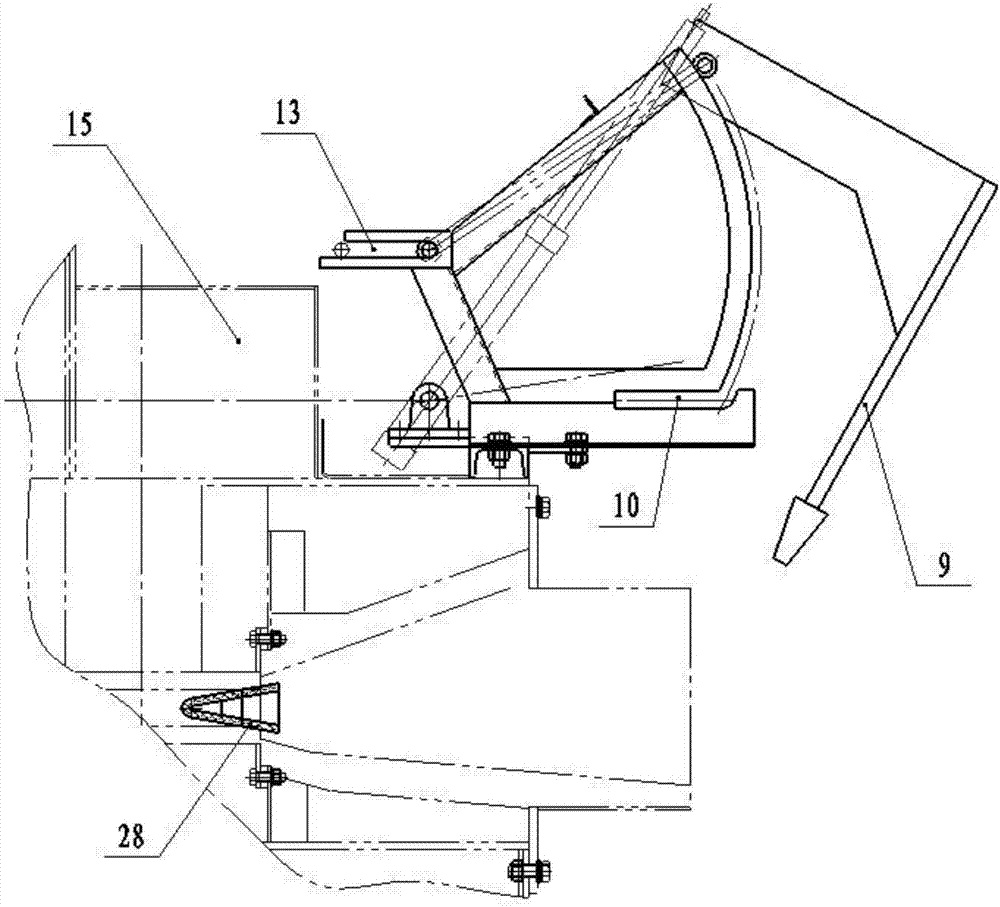

[0030] Such as Figure 1-7 Shown is a blocking method for the blocking device of the discharge port of a melting furnace. The blocking device includes a cylinder 1, a blocking assembly 2 and a limit slide rail assembly 3. The block assembly 2 is a movable part, and the limit slide rail assembly 3 is a stationary part. The blocking assembly 2 realizes the blocking or opening of the discharge port 18 through the positioning and guiding of the limiting slide rail assembly 3 under the action of the cylinder 1, such as Figure 4-5 As shown, the plugging assembly 2 includes an L-shaped stopper rod 4 and a stopper rod frame-shaped support 5, the front end of the stopper rod frame-shaped support 5 is provided with a front connecting shaft 6, and the rear end of the stopper rod frame-shaped support 5 is provided with a rear connection shaft 7 , the upper end of the L-shaped stopper rod 4 is a U-shaped support 8, the lower end of the L-shaped stopper rod 4 is a stopper rod 9, and the L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com