A sliding limit type kiln outlet plugging system

A discharge opening and position limiting technology, which is applied in the field of sliding limit kiln discharge opening blockage system, can solve problems such as poor sealing, inconvenient operation, and hidden dangers to the safety of operators, so as to achieve large blocking thrust and easy operation. Convenience, strong sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

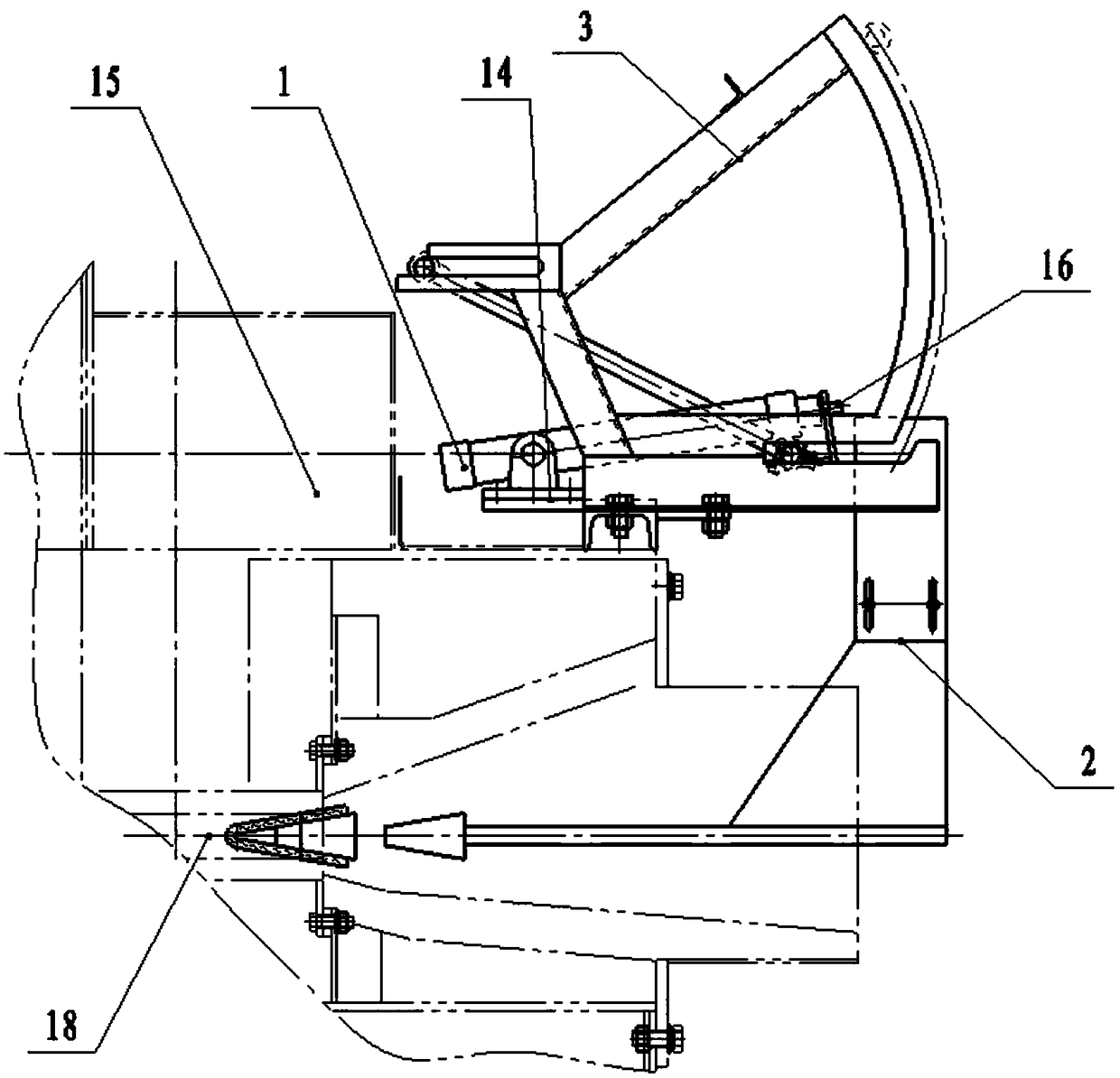

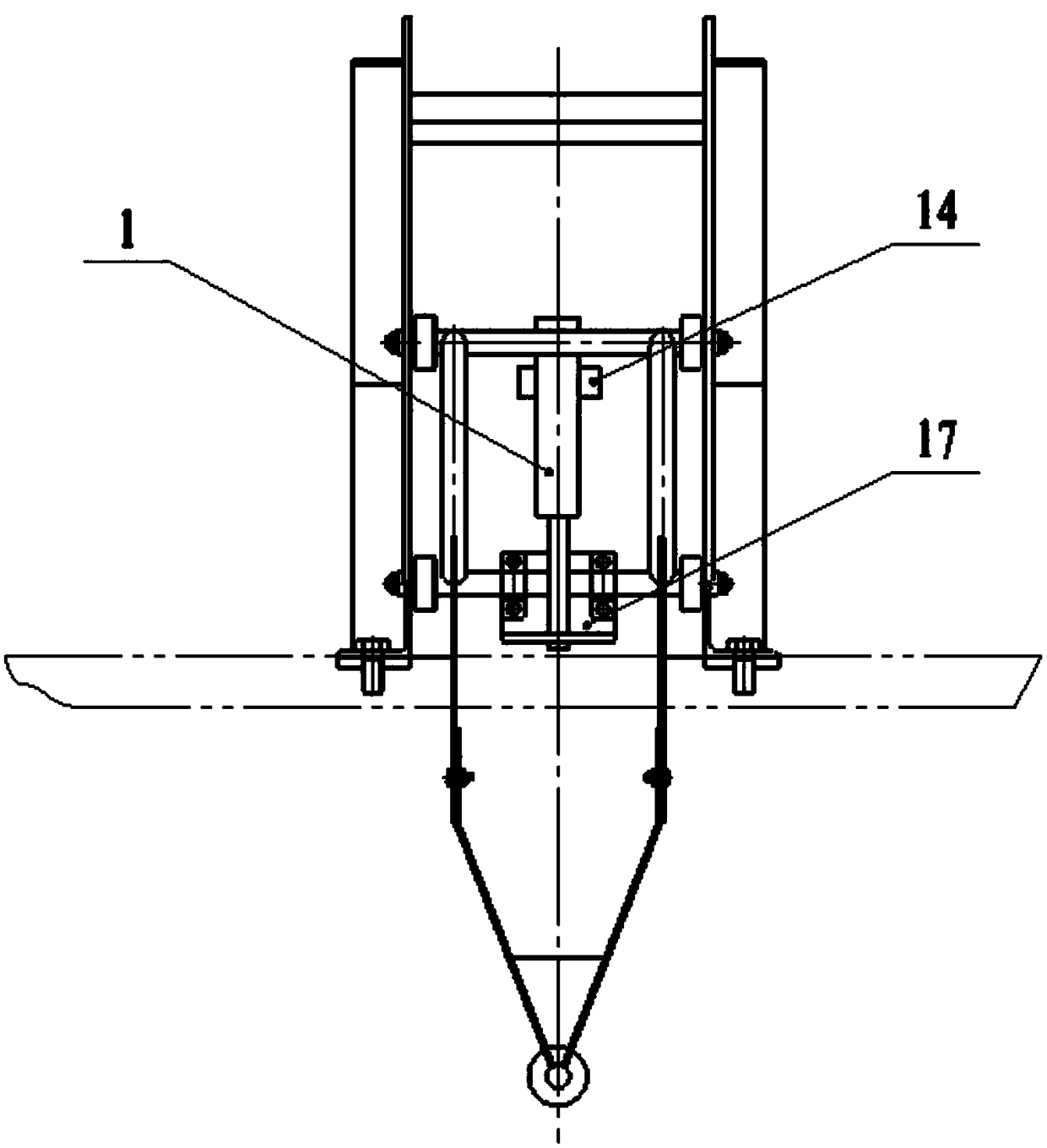

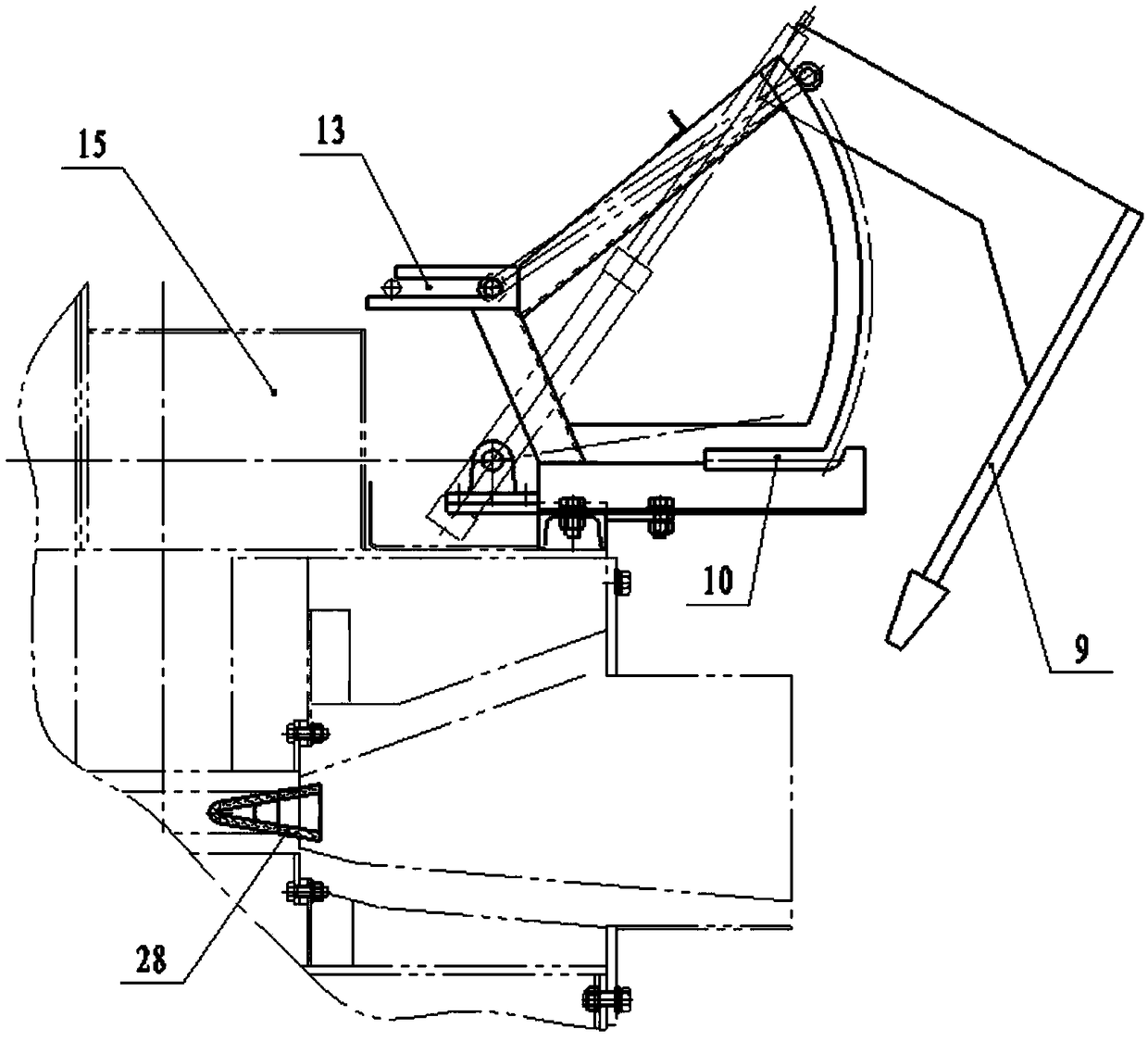

[0029] like Figure 1-7 The blockage system for the discharge port of a sliding limit type kiln shown includes a cylinder 1, a plug assembly 2 and a slide rail assembly 3, the plug assembly 2 is a movable part, the slide rail assembly 3 is a stationary part, and the plug assembly 2 Under the action of the cylinder 1, the blockage or opening of the discharge port 18 is realized through the limit and guidance of the slide rail assembly 3, such as Figure 4-5 As shown, the plug head assembly 2 includes an L-shaped plug rod 4 and a plug rod frame-shaped bracket 5, the front end of the plug rod frame-shaped bracket 5 is provided with a front connecting shaft 6, and the rear end of the plug rod frame-shaped bracket 5 is provided with a rear connecting shaft 7. The upper end of the L-shaped plug rod 4 is a U-shaped bracket 8, the lower end of the L-shaped plug rod 4 is a plug rod 9, and the L-shaped plug rod 4 is connected to the plug rod frame-shaped bracket through the U-shaped bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com