Intelligent flexible pickup truck carriage switching system

A switching system and flexible technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problem of low production capacity of the main line, achieve the effect of improving the production capacity of the main line, reducing manufacturing costs, and reducing personnel and site investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

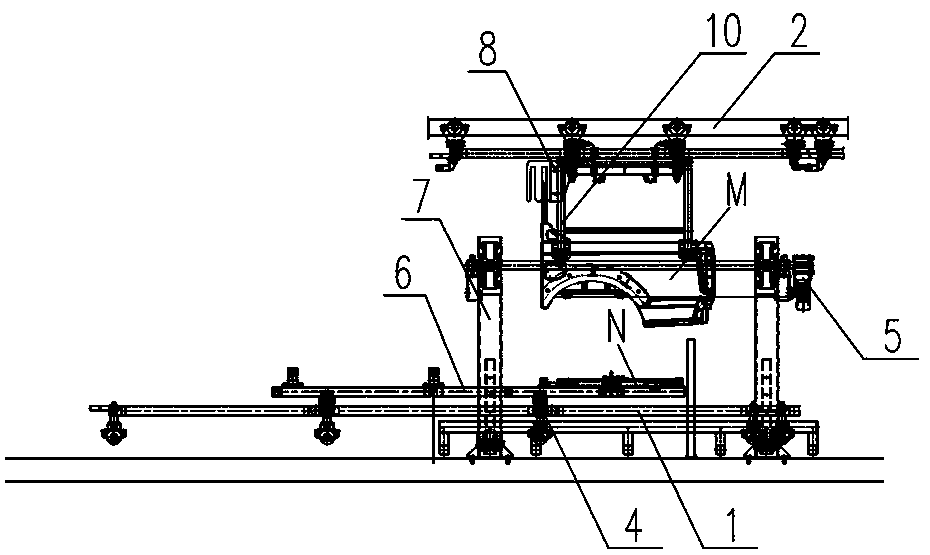

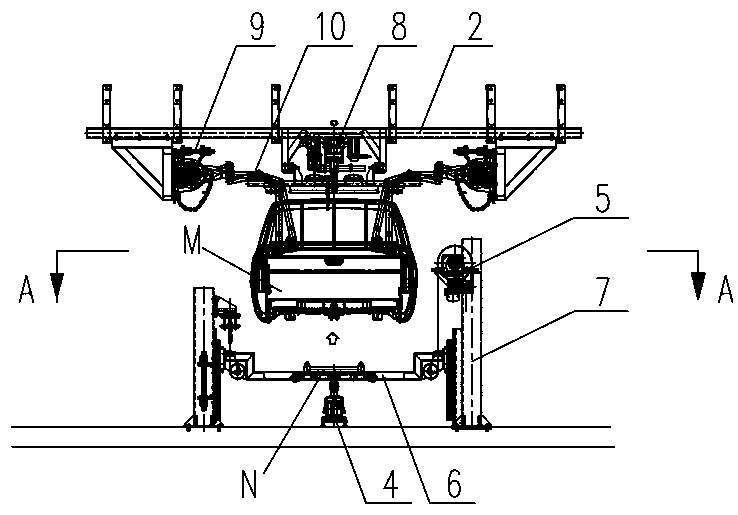

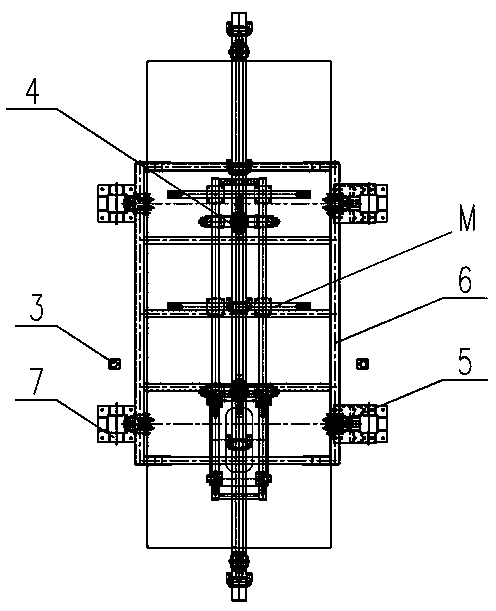

[0020] The intelligent and flexible pick-up box transfer system according to the present invention includes a PLC control system and a trolley conveying part, and also includes a pickup truck car conveying part, which is arranged above the trolley conveying part and connected to the storage sorting line; part, which is arranged between the trolley conveying part and the pickup truck box conveying part, and is used to transfer the pickup truck box from the trolley conveying part to the pickup truck box conveying part; the signal recognition part, which is arranged near the trolley conveying part and is controlled with PLC The electrical connection of the system is used to judge whether the workpiece on the trolley is a pickup truck box and transmit the corresponding electrical signal to the PLC control system. The PLC control system controls whether the lifting adapter works according to the electrical signal.

[0021] The embodiments of the present invention will be described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com