Automatic oil spraying and cleaning equipment for gear shifting fork assembly

A technology for shifting forks and cleaning equipment, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

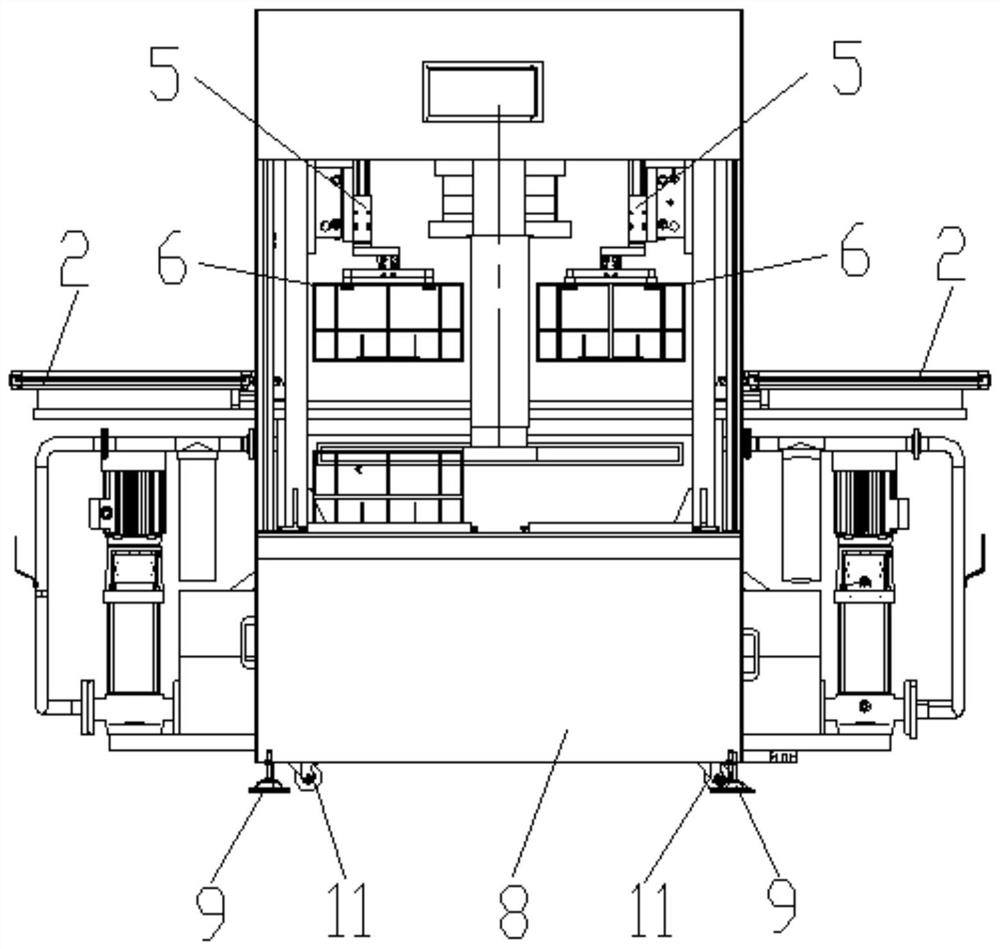

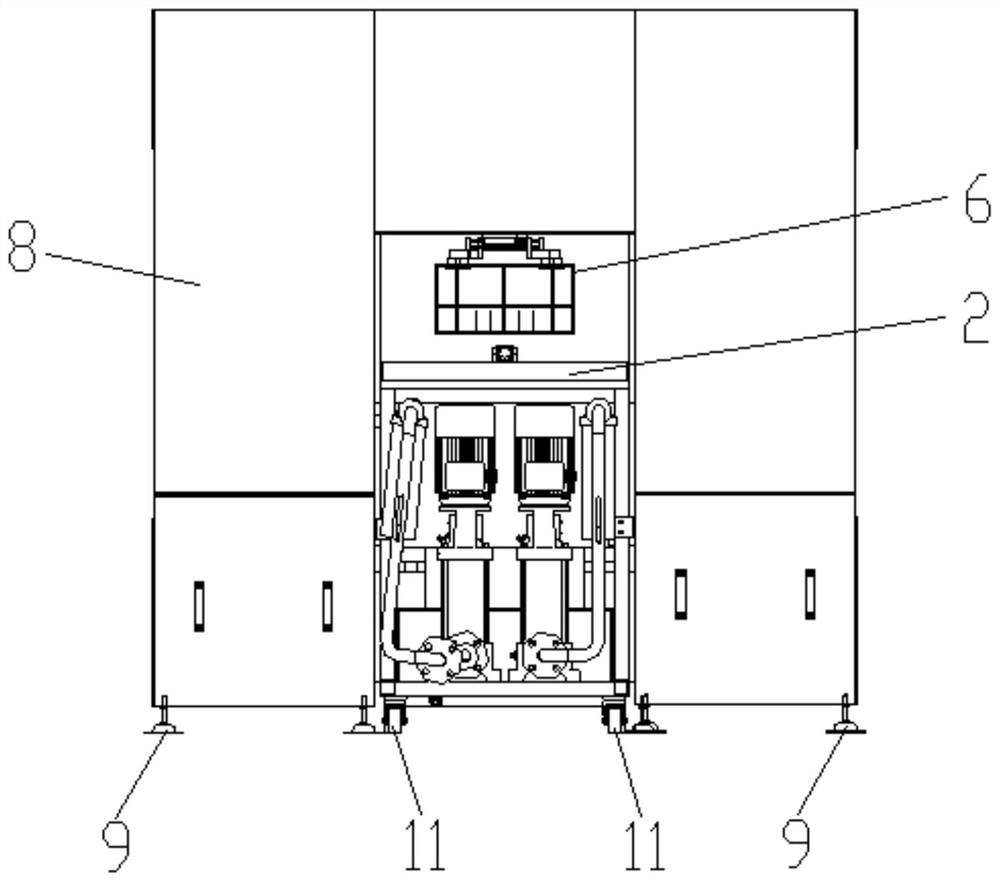

[0039] On the basis of the above structure, this embodiment also includes a workbench 8 on which the above-mentioned loading and unloading device and cleaning device are respectively installed, which has a high degree of integration and is easy to use.

Embodiment 2

[0041] On the basis of Embodiment 1, preferably, in this embodiment, a plurality of walking wheels 11 are installed at even intervals on the bottom of the above-mentioned workbench 8, which facilitates the movement of the entire device and is easy to use.

[0042] Preferably, in this embodiment, each road wheel 11 is preferably a universal wheel with brakes, which can stop and go as it goes, which is more convenient to use.

Embodiment 3

[0044] On the basis of any one of Embodiment 1 to Embodiment 2, in this embodiment, a plurality of support plates 9 are evenly spaced on the top of the workbench 8, and each support plate 9 can move up and down and be positioned. During use, the workbench 8 can be supported by a plurality of support discs 9 .

[0045] Based on the above scheme, when the supporting disc 9 and the traveling wheels 11 exist at the same time, the specific usage principle is: when the whole device needs to be moved, manually move the multiple supporting discs 9 up until they are separated from the ground, and then move the whole device That is enough; when cleaning is required, the plurality of support plates 9 can be manually moved down until they fit the ground, so as to increase the stability of the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com