Generator brush current on-line monitoring system

A brush current and monitoring system technology, applied in the direction of measurement using digital measurement technology, can solve problems such as overheating disconnection, disconnection, increased carbon brush wear, etc., to achieve easy operation, simple system structure, and ensure stability and reliability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

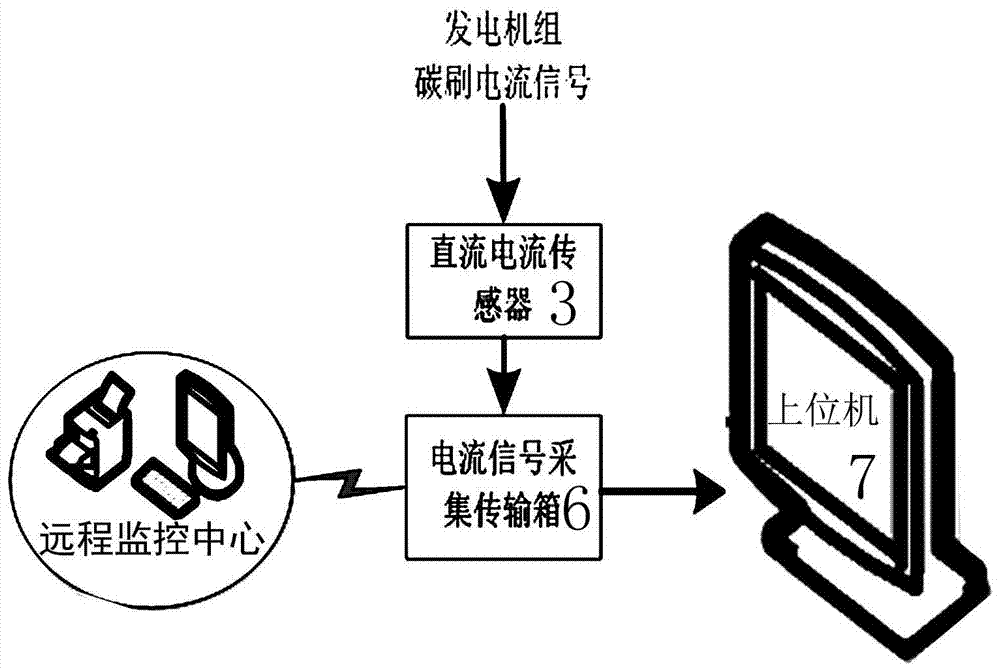

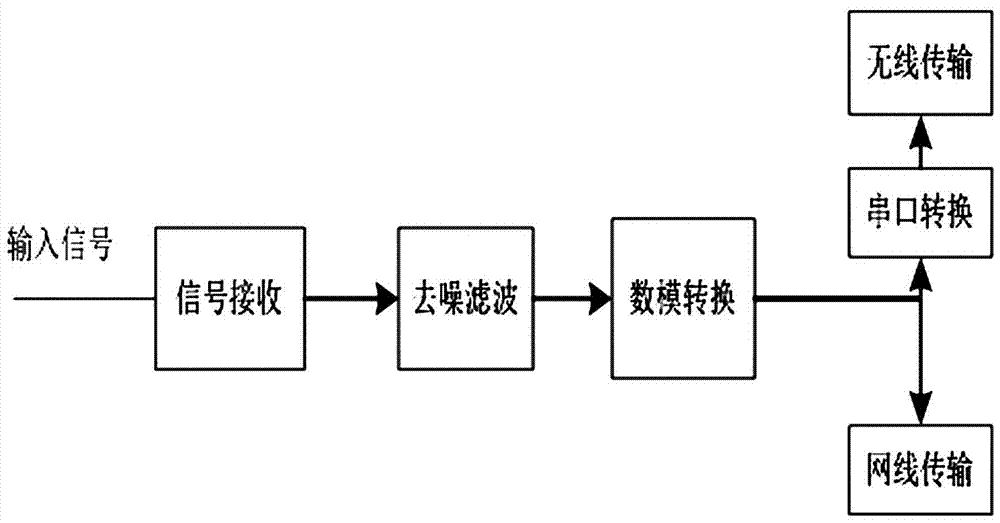

[0019] The present invention is an on-line monitoring system for generator brush current, such as figure 1 as shown, figure 1 It is the framework diagram of the generator carbon brush current distributed monitoring system. In the present invention, the DC current sensor 3 is fixedly installed on each carbon brush braid 4, and the DC current sensor 3 is connected to the current signal acquisition transmission box 6 through the shielded transmission line 5; the current signal acquisition transmission box 6 is connected to the upper computer 7 through the network cable , the other path of the current signal acquisition transmission box 6 is directly sent to the remote monitoring center by the wireless transmitting module after being converted by the serial port.

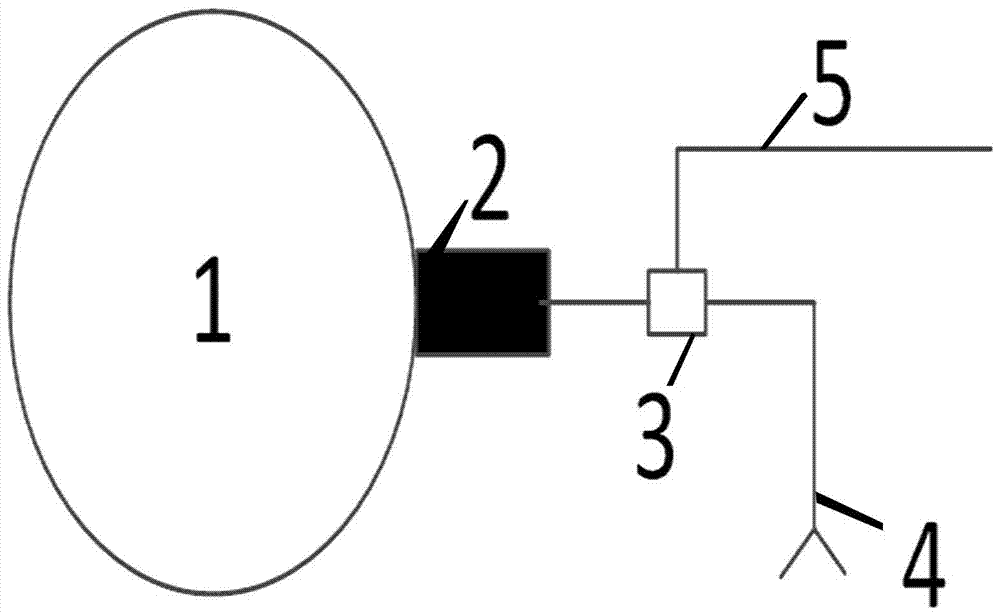

[0020] Such as figure 2 as shown, figure 2 Schematic diagram of the installation position of the DC current sensor. The DC current sensor 3 is fixedly connected to the carbon brush pigtail 4, and is indirectly ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com