Roller motor and use method thereof

A drum motor and drum technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as troubles, achieve the effect of ensuring normal operation and reducing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below with reference to the accompanying drawings and embodiments.

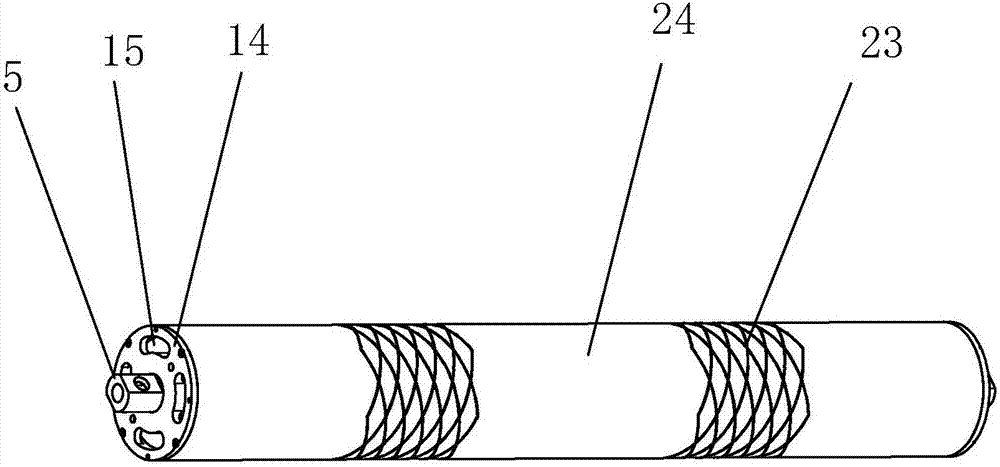

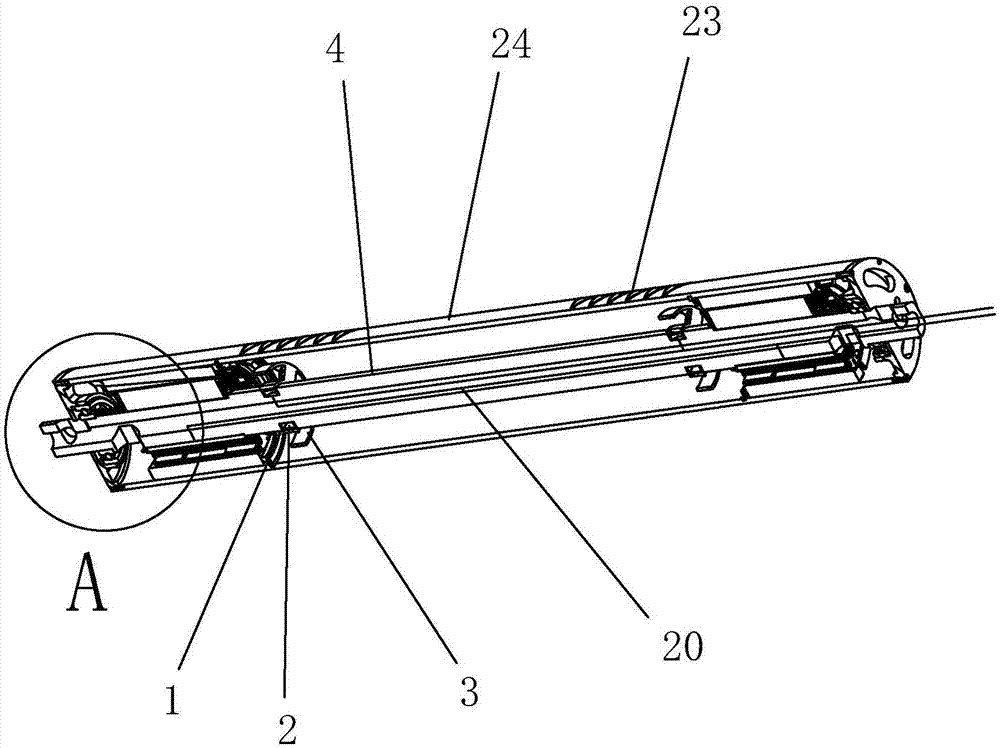

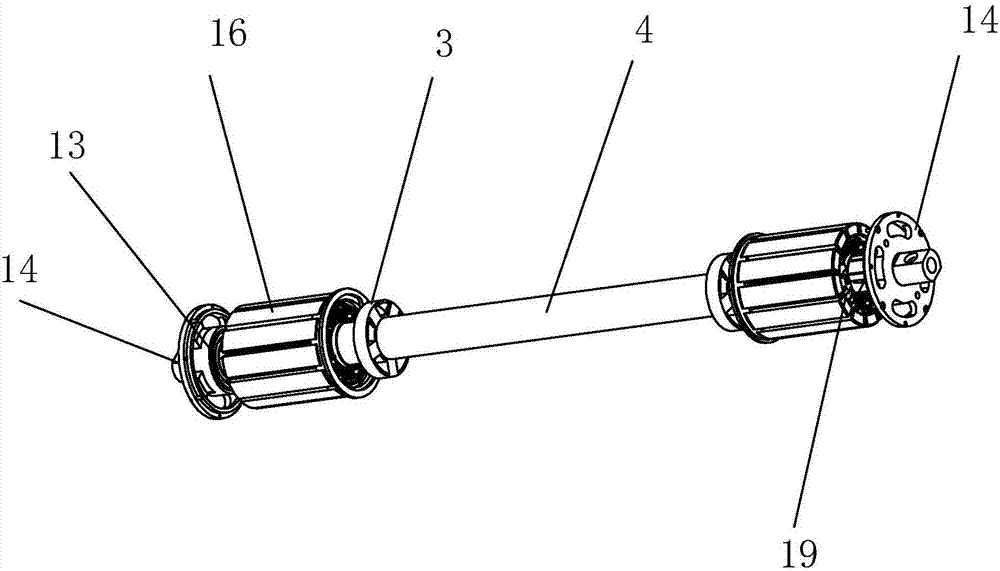

[0054] like Figure 1-Figure 11 As shown, a drum motor in this embodiment is characterized in that, the drum motor includes:

[0055] fixed shaft;

[0056] bearing assemblies arranged at both ends of the fixed shaft for bearing radial load;

[0057] a drum 24 arranged outside the fixed shaft and rotatable around the fixed shaft through the bearing assembly;

[0058] a stator assembly arranged on the fixed shaft;

[0059] and a rotor assembly disposed on the drum 24 and opposite to the stator assembly.

[0060] When the embodiment of the present invention is in use, the stator assembly is energized to make it interact with the rotor assembly, and the mutual rotation of the two is completed through the principle that the energized conductor can generate a force in the excitation magnetic field. Here, the rotor assembly is arranged on the inner side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com