Vertical windrower dividing device

A windrower and crop dividing technology, which is applied in the direction of harvester, external crop divider, and harvesting table, can solve the problems of plant branch entanglement, large crop loss, and thick plant stalk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

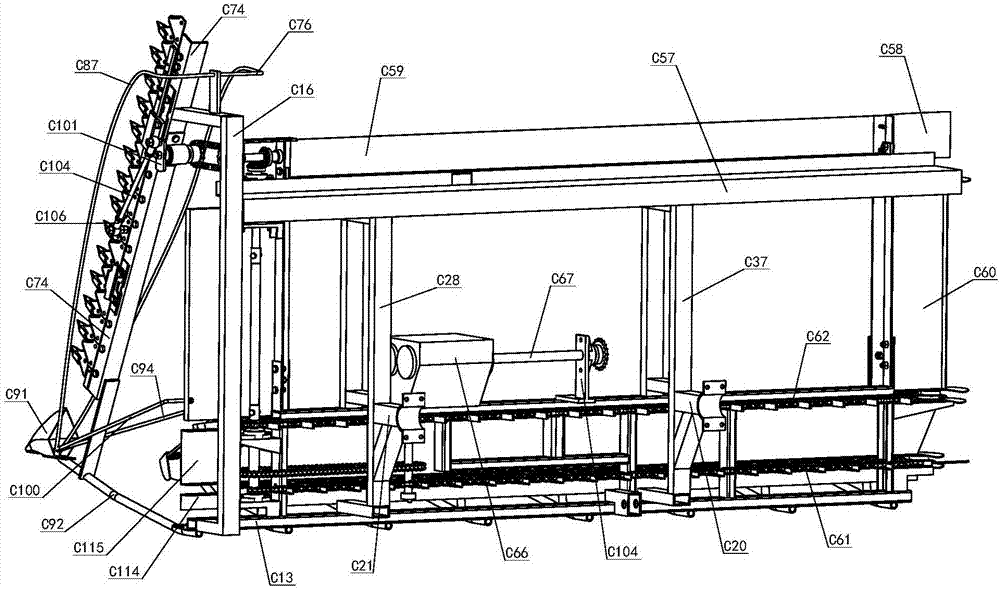

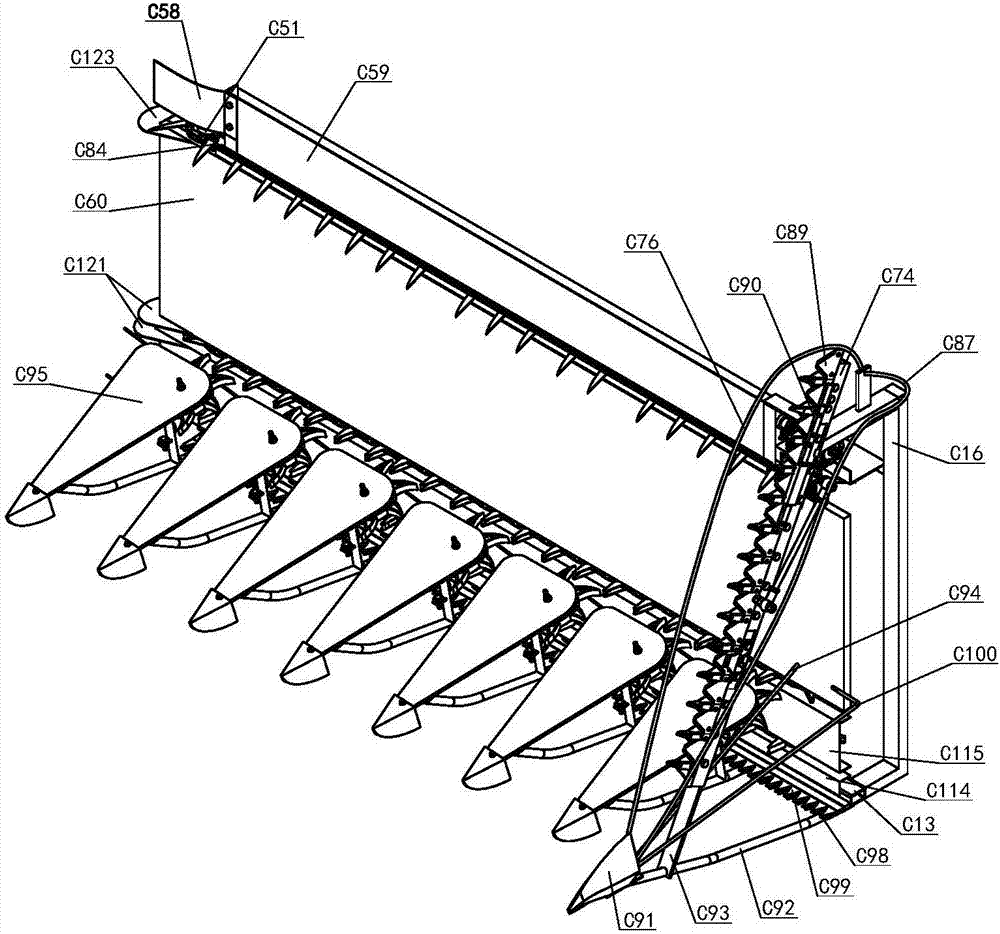

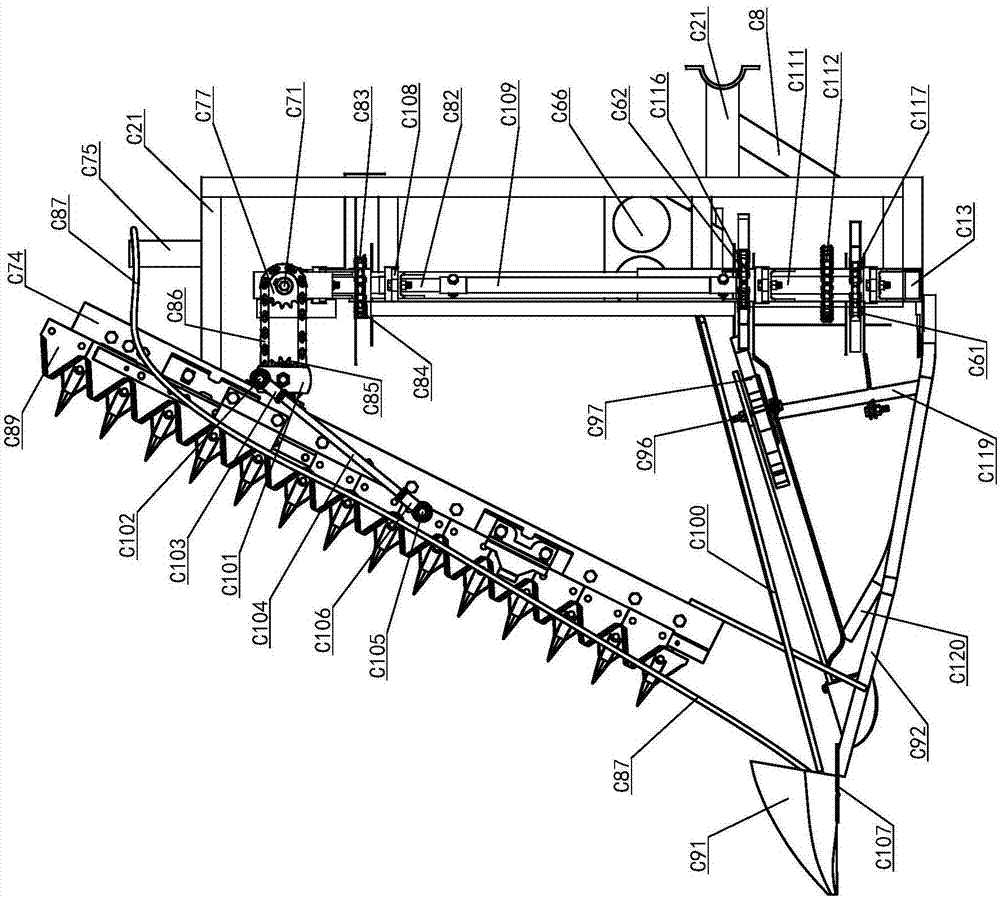

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0039] see Figure 1 to Figure 13 A vertical windrower splitting device, comprising a header first bracket 20, a header second bracket 21, a header third bracket C1, a header fourth bracket C2, a header fifth bracket C3, and a header Sixth bracket C5, header seventh bracket C6, header eighth bracket C7, header ninth bracket C8, header tenth bracket C9, header eleventh bracket C10, header first bearing seat bracket C11, The twelfth bracket of the header C12, the thirteenth bracket of the header C13, the fourteenth bracket of the header C14, the second bearing seat bracket of the header C15, the fifteenth bracket of the header C16, the sixteenth bracket of the header C17, The seventeenth bracket of the header C18, the third bearing bracket of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com