Vertical type windrower dividing method

A windrower and crop dividing technology, which is applied in the direction of harvester, external crop divider, harvesting table, etc., can solve the problems of blocking, falling on the field, and thick plant stalks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

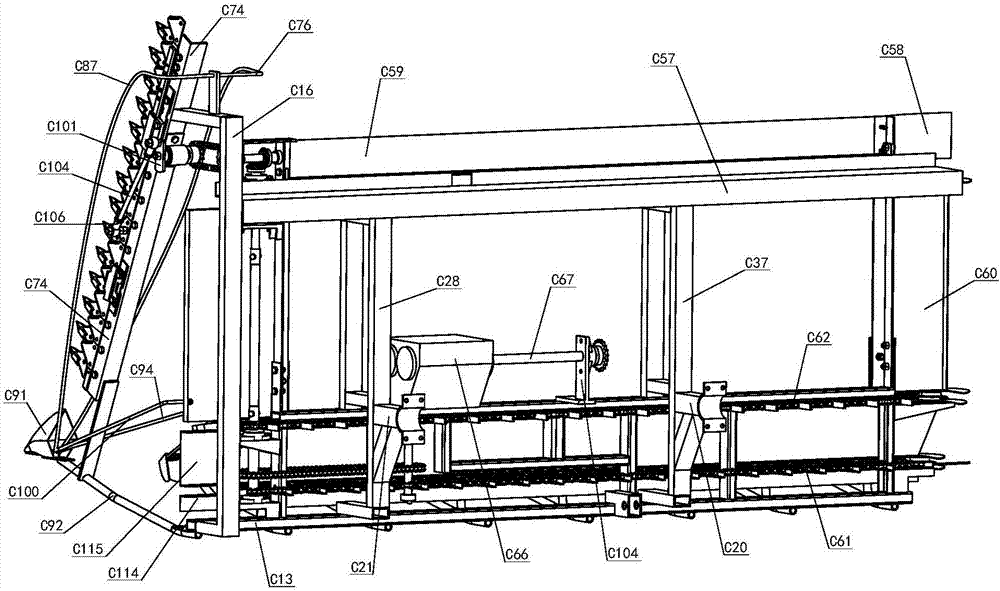

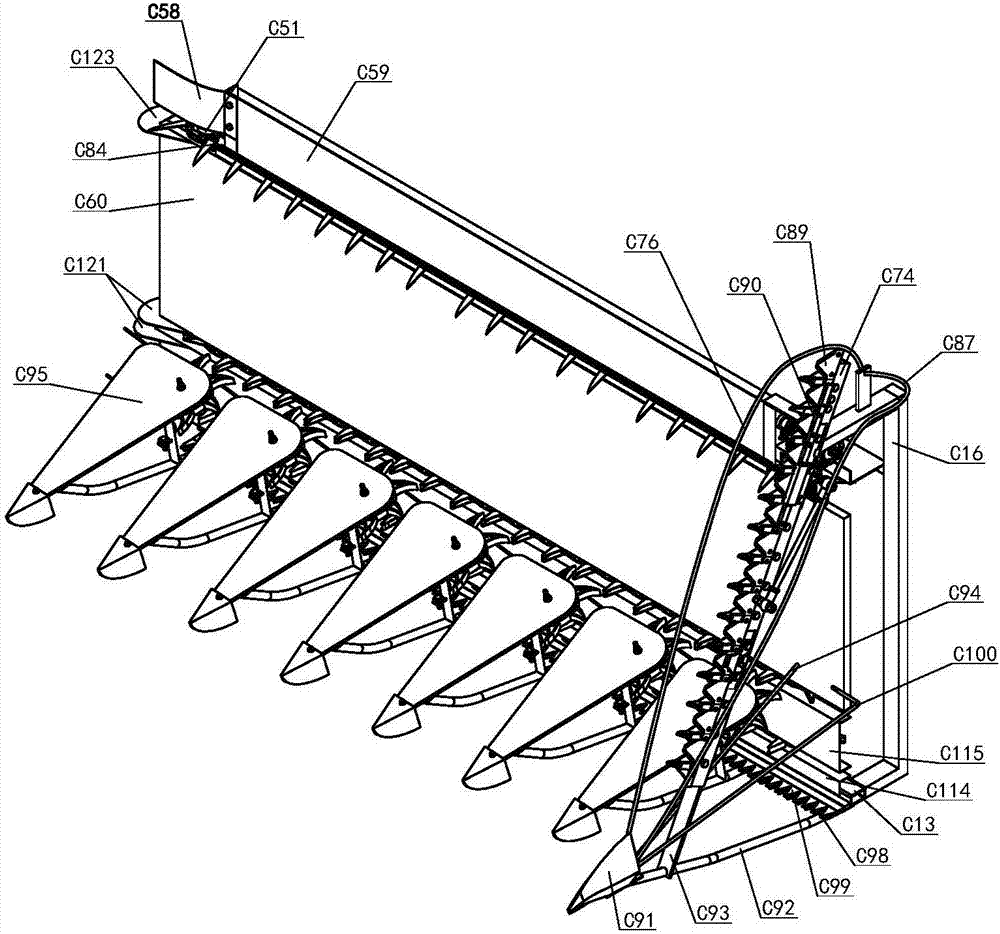

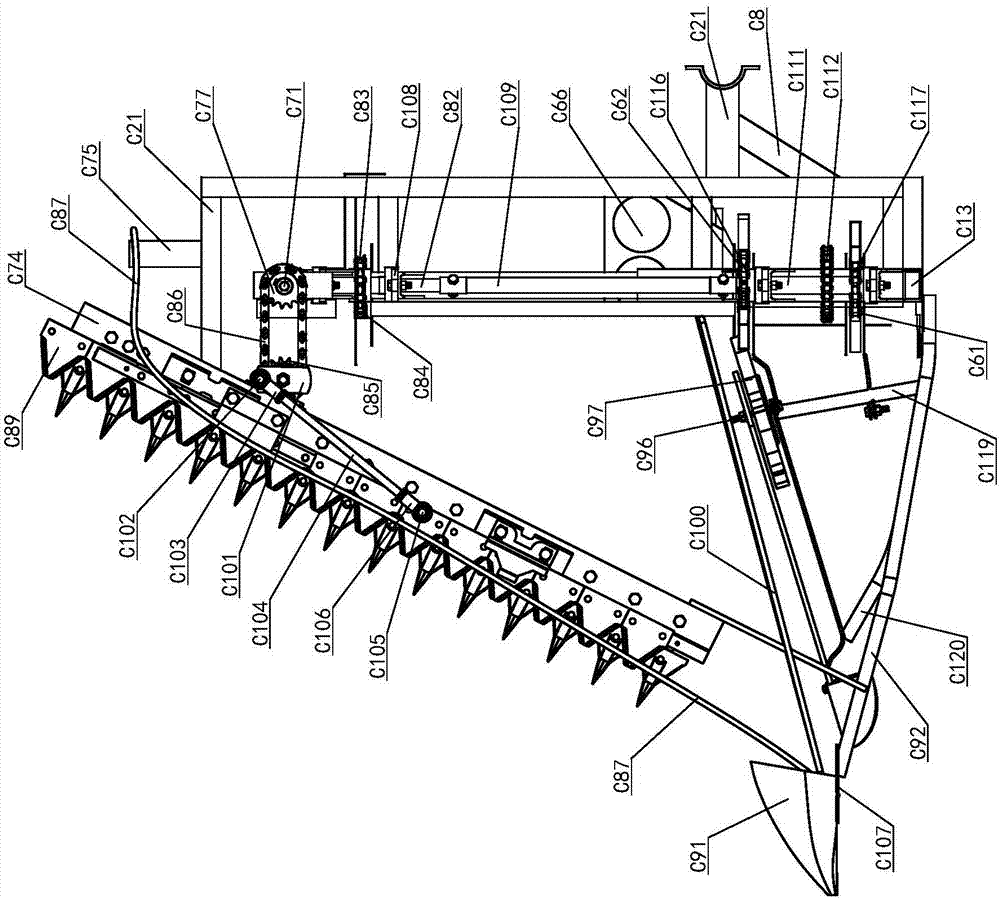

[0040] see Figure 1 to Figure 13A method for dividing crops of a vertical windrowing machine according to the present invention, adopting a vertical windrowing machine splitting device to implement the grain dividing operation, and the vertical windrowing machine splitting device is rotatable through the first bracket 20 of the header and the second bracket 21 of the header Installed on the intermediate connection device of the windrower, the power of the main engine is transmitted to the second transmission sprocket C70 of the header through the intermediate transmission device and drives the second transmission shaft C67 of the header to rotate, and the second transmission shaft C67 of the header transmits the power to the header The gearbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com