Automatic oolong tea leaf rolling machine based on sensor technology

A sensing technology and oolong tea technology, applied in the field of oolong tea automatic rolling machine, can solve the problems of low work efficiency, complicated rolling process, labor-intensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

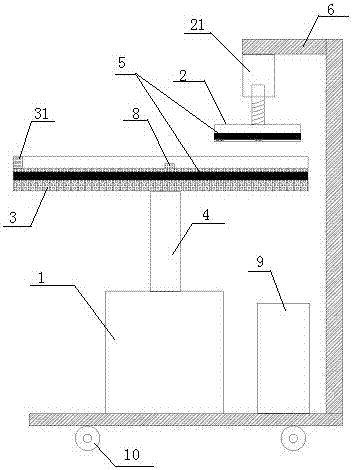

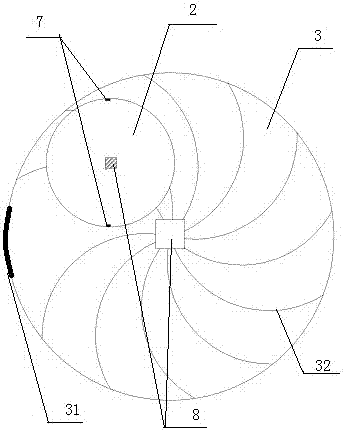

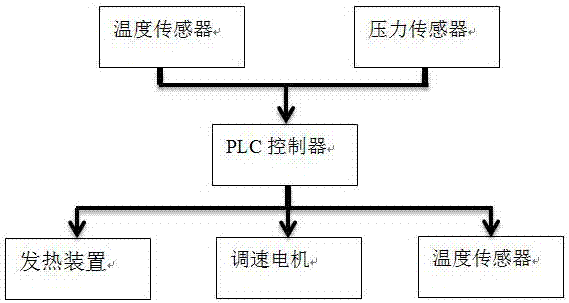

[0015] like Figure 1-3 A kind of oolong tea automatic kneading machine based on sensing technology shown, it comprises speed regulating motor 1, kneading board 2, kneading tank 3, rotating shaft 4, heating device 5, support 6, pressure sensor 7, temperature sensor 8, outlet Material port 31 and PLC controller 9, described speed-regulating motor 1 is fixedly installed on the bracket 6, and is connected with rotating shaft 4, and rotating shaft 4 is connected to kneading groove 3 again, drives rotating shaft 4 to rotate by speed-regulating motor 1 Thereby drive kneading groove 3 to rotate; Described kneading board 2 is connected to support 6 by screw lifting mechanism 21, can regulate the distance between kneading board 2 and kneading groove 3 by helical lifting mechanism 21; Described heating device 5 is fixed respectively Be installed in kneading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com