Epoxy resin carbon steel concrete composite stand column for marine environment

A technology of epoxy resin and marine environment, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of wind turbine instability, loss, collapse, etc., and achieve the effect of large bearing capacity, high rigidity, and good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

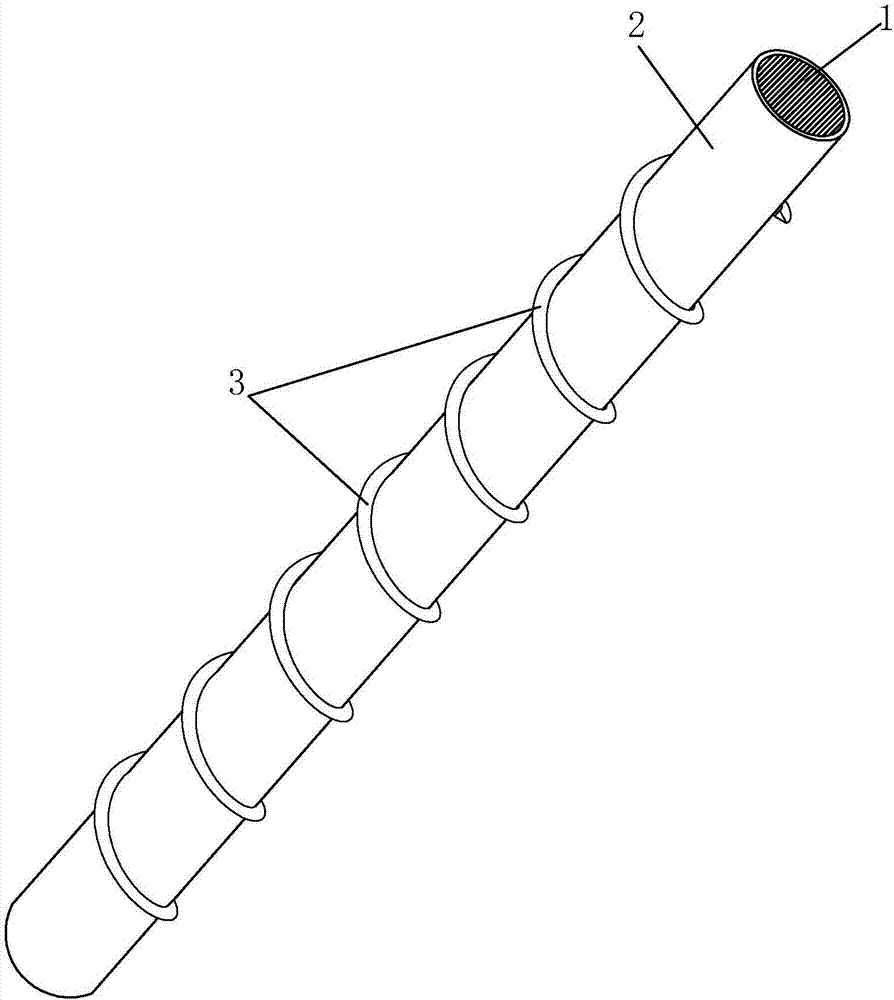

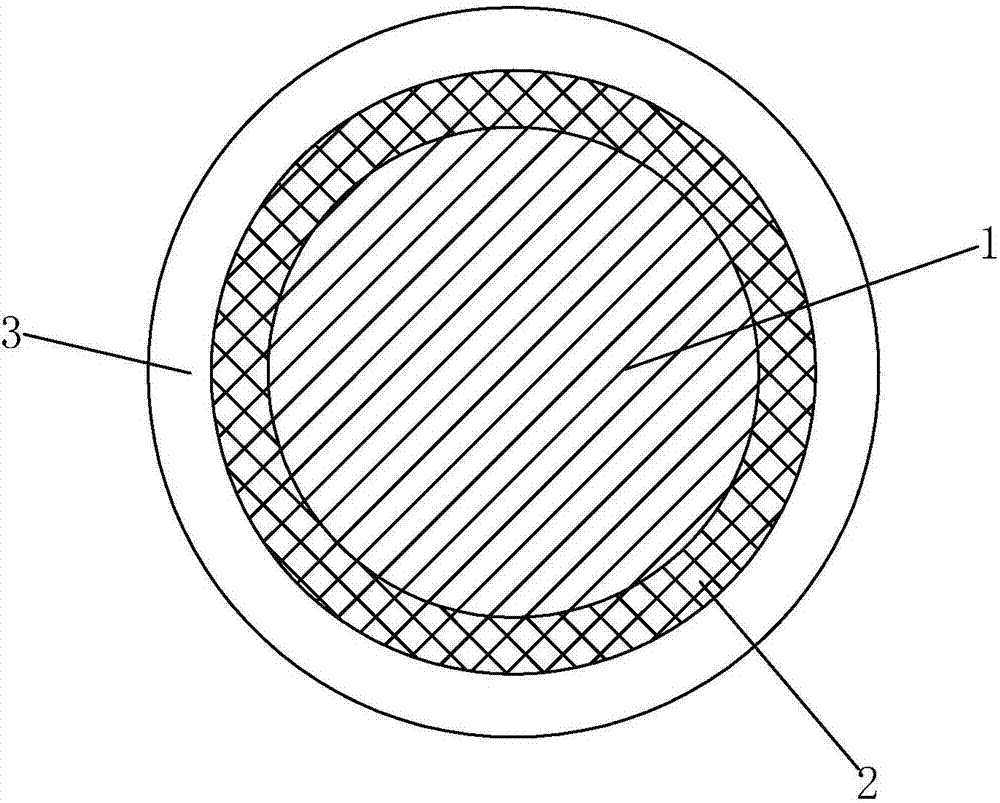

[0025] Such as figure 1 and 2 Shown, a kind of epoxy resin carbon steel concrete composite column for marine environment comprises a core concrete column 1 (the shape of the cross section is preferably circular, elliptical or polygonal), a carbon steel pipe 2 and a ring epoxy tube 3;

[0026] The core concrete column 1 is filled and adapted in the carbon steel pipe 2, so that the core concrete column 1 is effectively restrained by the carbon steel pipe 2, the bearing capacity and deformation capacity of the core core concrete column 1 are improved, and the carbon steel pipe 2 is covered by the core concrete The support of the column 1 prevents the concave yield damage of the carbon steel pipe 2, and improves the stable bearing capacity of the carbon steel pipe 2, wherein the material specification of the carbon steel pipe 2 is Q235;

[0027] The epoxy resin tube 3 is spirally wrapped around the outer wall of the carbon steel tube 2 to effectively alleviate the vortex-induced...

Embodiment 2

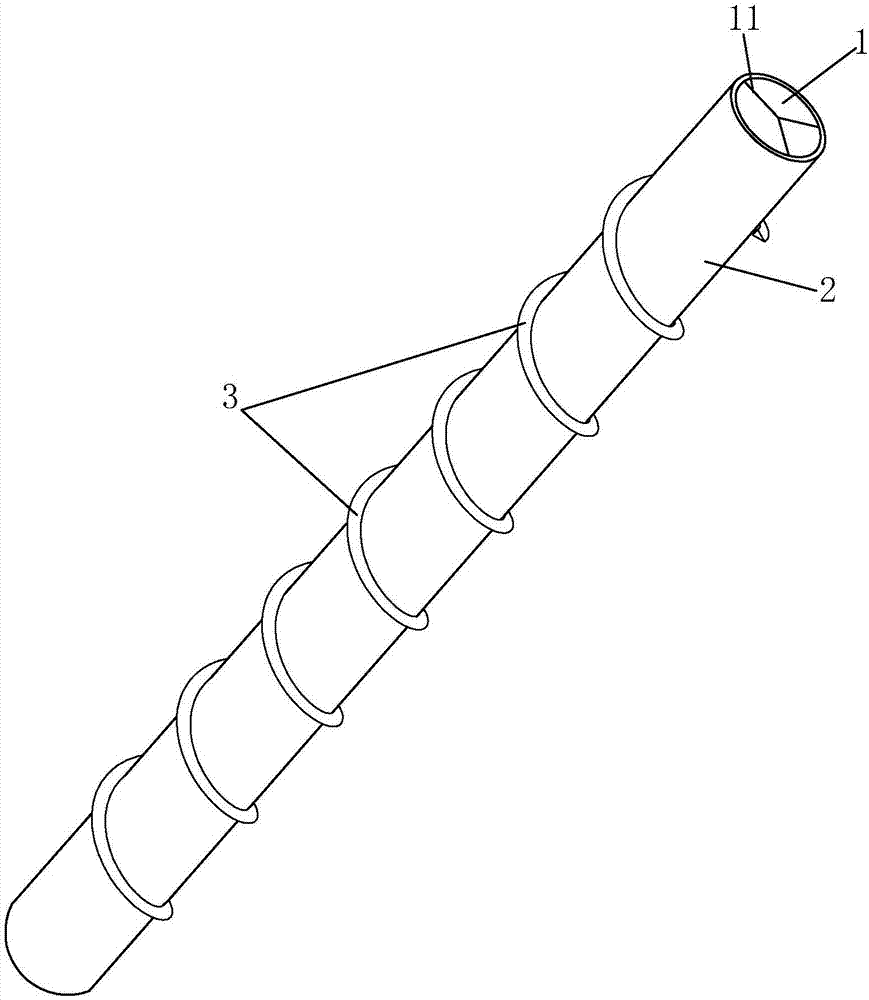

[0036] Such as image 3 and 4 Shown, a kind of epoxy resin carbon steel concrete composite column for marine environment comprises a core concrete column 1 (the shape of the cross section is preferably circular, elliptical or polygonal), a carbon steel pipe 2 and a ring epoxy tube 3;

[0037] The core concrete column 1 is filled and adapted in the carbon steel pipe 2, so that the core concrete column 1 is effectively restrained by the carbon steel pipe 2, and the bearing capacity and deformation capacity of the core concrete column 1 are improved, and at the same time, the carbon steel pipe 2 is surrounded by the core concrete column. 1 support to prevent concave yield damage of carbon steel pipe 2 and improve the stable bearing capacity of carbon steel pipe 2, wherein the material specification of carbon steel pipe 2 is Q235;

[0038] The epoxy resin tube 3 is spirally wrapped around the outer wall of the carbon steel tube 2 to effectively alleviate the vortex-induced vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com