Anti-roll bar with active adjusting function for self-generating new energy vehicles

A new energy vehicle, active adjustment technology, applied in the direction of generators/motors, electrical components, electromechanical devices, etc., can solve the problems of limiting active anti-roll bars, high material consumption, stiffness adjustment lag, etc., to improve active adaptation ability, high adjustment accuracy, and the effect of adjusting the speed block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

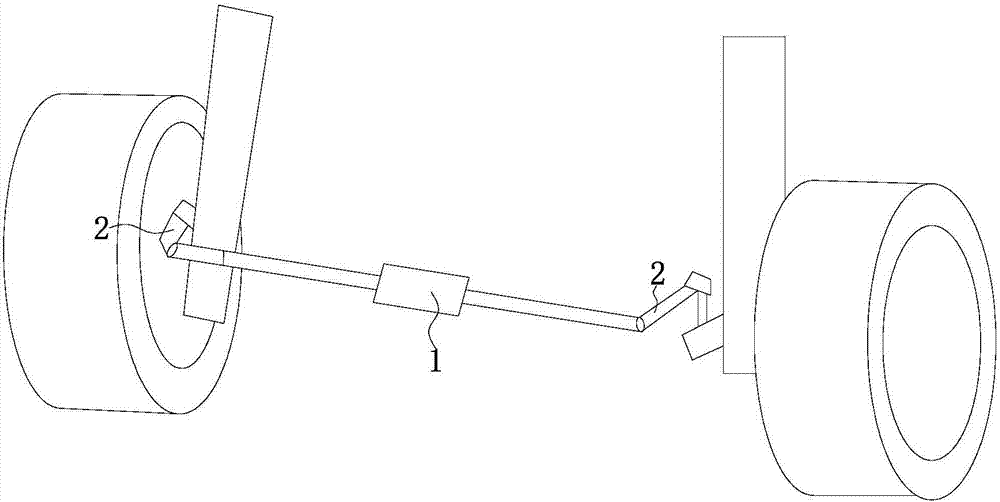

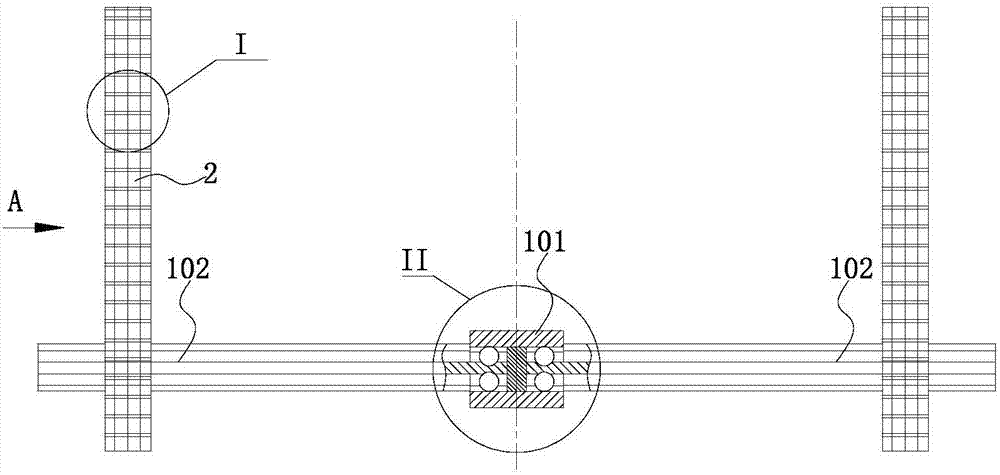

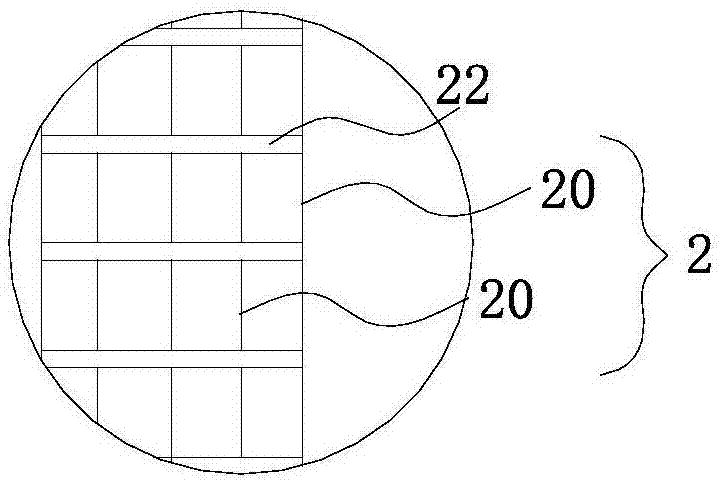

[0029] like Figure 1-Figure 11 The anti-roll bar for a self-generating new energy vehicle with an active adjustment function shown includes a torsion bar 1 horizontally arranged below the vehicle frame in the transverse direction of the vehicle, and the torsion bar 1 includes a hollow central connecting cylinder 101;

[0030] The two ends of the central connecting cylinder 101 are respectively sleeved together with one end of a connecting torsion bar 102, and a force transmission block 103 is arranged between the two connecting torsion bars 102 in the central connecting cylinder 101, and the connecting torsion bar 102 can be moved along the The central connecting cylinder 101 slides in the axial direction and can rotate together with the central connecting cylinder 101. The two ends of the force transmission block 103 are respectively in contact with the ends of a connecting torsion bar 102; the connecting torsion bar 102 The other end passes through the side of one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com