Exposure photomask and graphic modeling method of photoresist material

A photoresist material, patterning technology, applied in the field of photoresist material patterning and exposure mask, can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

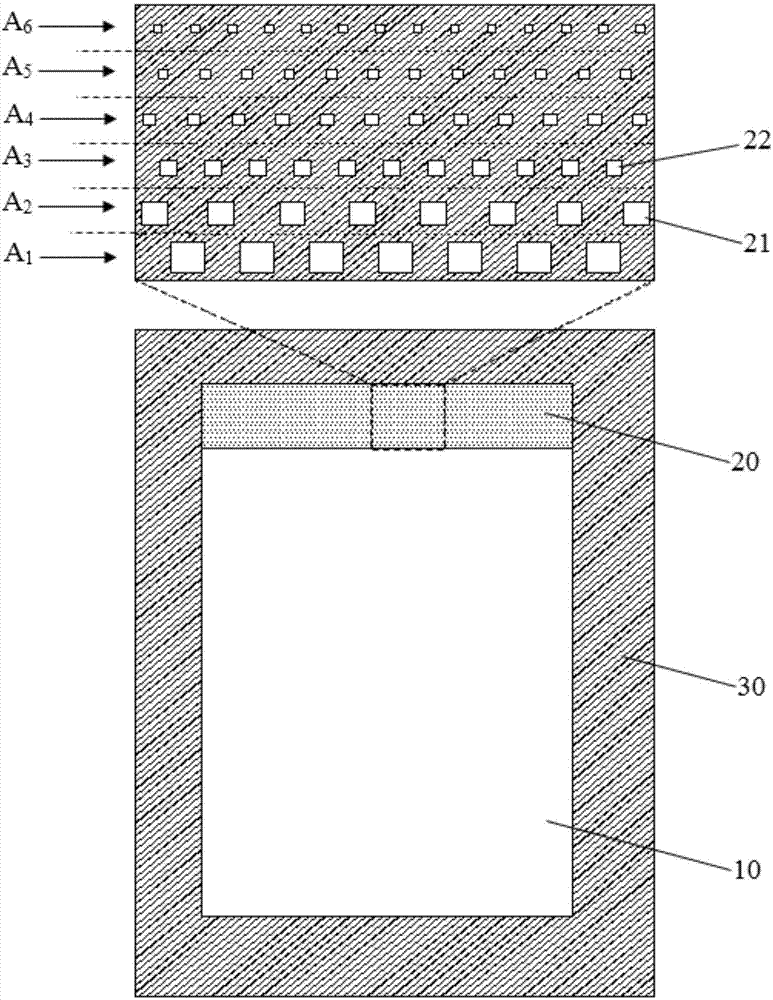

[0032] This embodiment provides an exposure mask, such as image 3 As shown, the exposure mask includes a first exposure area 10, a second exposure area 20 and a light shielding area 30 surrounding the first exposure area 10 and the second exposure area 20, and the second exposure area 20 is adjacent to the The edge of the first exposure area 10 is set. Wherein, the second exposure region 20 includes the first to Mth sub-exposure regions A arranged in parallel in sequence in a direction gradually away from the first exposure region 10 1 ~A M , and, the nth sub-exposure area A n The exposure resolution is greater than the n+1th sub-exposure area A n+1 exposure resolution. Wherein, M is an integer greater than 2, and n=1, 2, 3, . . . , M-1. In this example, if image 3 exemplarily shows 6 sub-exposure areas A 1 ~A 6 , that is, the value of M is 6, and in some other preferred embodiments, the value range of M is preferably 6-10.

[0033] It should be noted that the expos...

Embodiment 2

[0040] This embodiment provides a photoresist patterning method, see Figures 4a-4e , the method includes the steps of:

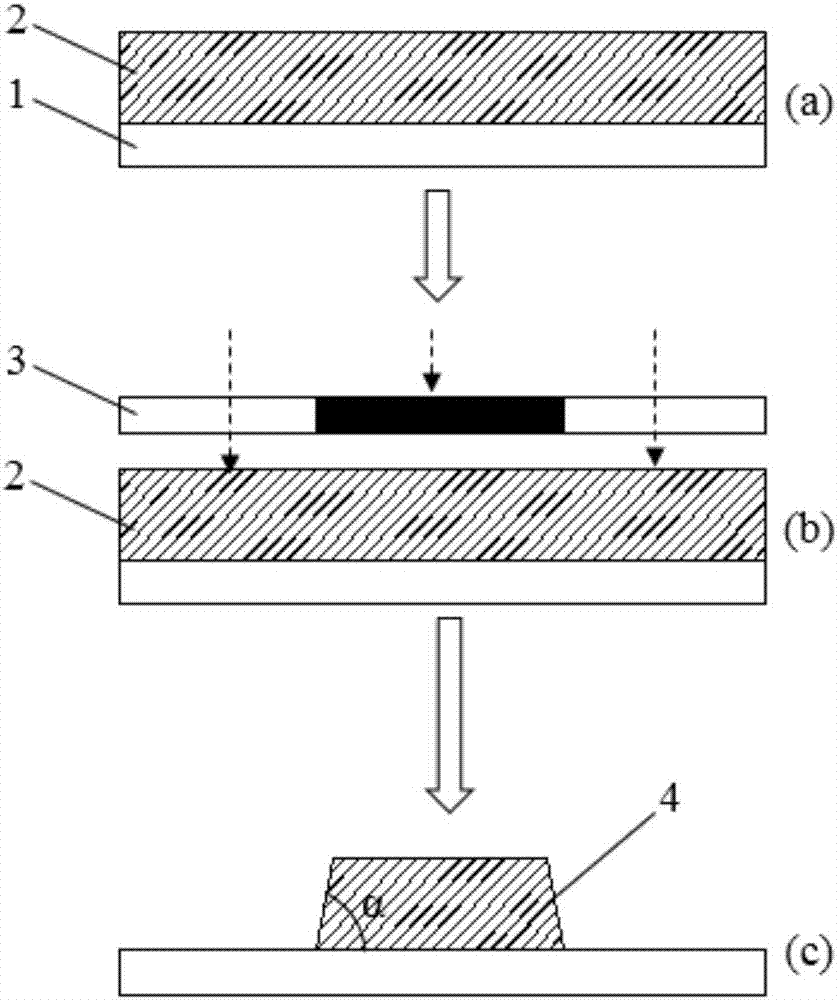

[0041] Step S1, such as Figure 4a As shown, a photoresist material layer 2 is coated on a base substrate 1 .

[0042] Step S2, such as Figure 4b As shown, the first exposure mask 3 is used to expose the photoresist material layer 2 . Wherein, the first exposure mask 3 is a conventional exposure mask in the prior art, and the dotted arrows in the figure indicate exposure light.

[0043] Step S3, such as Figure 4c As shown, the photoresist material layer 2 is developed to form a patterned first photoresist structure layer 4 . The slope angle of the first photoresist structure layer 4 is α 1 .

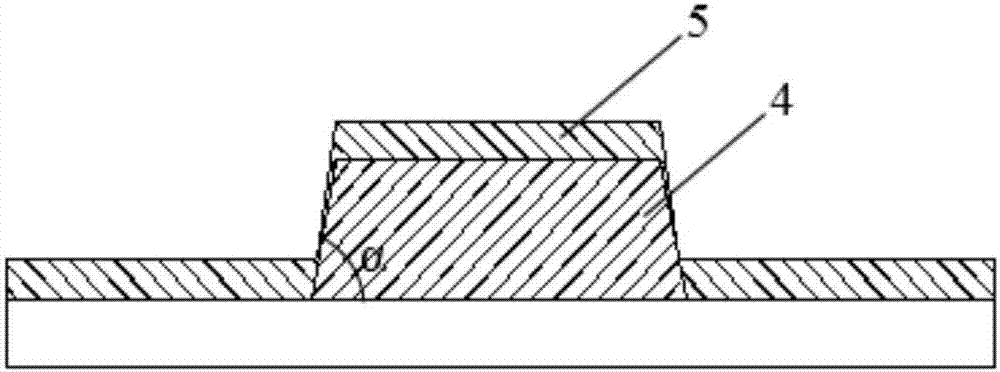

[0044] Step S4, such as Figure 4d As shown, on the first photoresist structure layer 4, a second exposure mask 5 is applied to expose a designated position where the slope angle needs to be adjusted. Specifically, the second exposure mask 5 is the exposure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com