Mixing equipment for manufacturing beef cattle feed

A technology of mixing equipment and feed, applied in feed, mixer with rotating stirring device, application, etc., can solve the problems of reducing feed production efficiency, and achieve the effect of improving mixing efficiency and mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

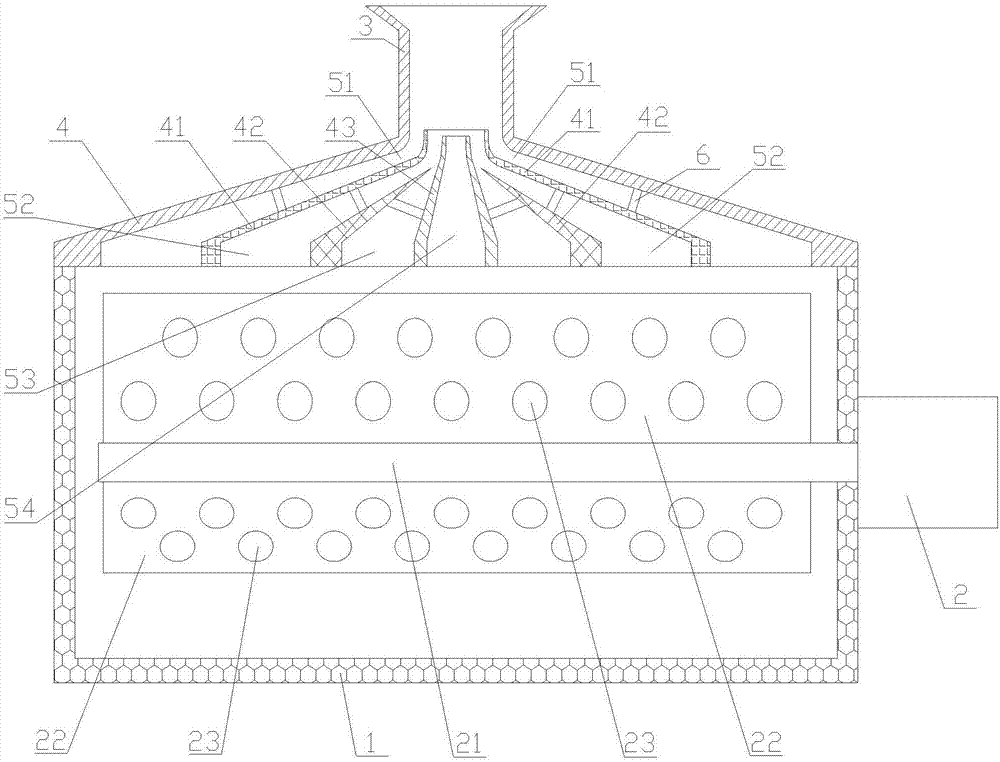

[0020] Such as figure 1 As shown, the present invention is used for the mixing equipment of beef cattle feed, comprises the mixing cylinder 1 of horizontal recumbency, and the both ends of mixing cylinder 1 are closed and is fixed with decelerating motor 2 outside mixing cylinder 1, and the output of decelerating motor 2 The shaft 21 passes through the side wall of the mixing barrel 1 and is placed in the mixing barrel. The axis of the output shaft 21 coincides with the axis of the mixing barrel 1. The output shaft 21 is provided with a stirring blade 22, and a feeder is provided above the mixing barrel. Cylinder 3, a distribution cylinder 4 is arranged between the feed cylinder 3 and the mixing cylinder 1, the distribution cylinder 4 is triangular in shape, the top communicates with the feed cylinder, and the bottom communicates with the mixing cylinder. The barrel 4 is provided with several triangular-shaped shunt pipes, which divide the feed entering the feed barrel and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com