Stamping device capable of automatically correcting stamping workpieces and working method of stamping device

A punching device and a technology for stamping workpieces, which are applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve problems such as difficult to find and find problems, and achieve the effects of reasonable structural design, avoiding danger, and ensuring stamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

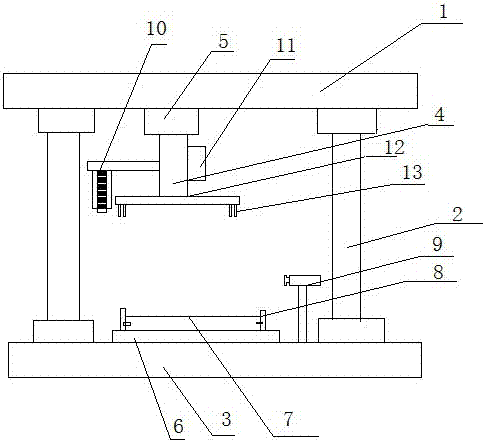

[0025] like figure 1 Shown is a stamping device and its working method for automatically correcting stamping workpieces. The stamping device includes an upper die base 1, a guide column 2, a lower die base 3, a punch 4, a punch holder 5, a punching table 6, a forming Mold 7, mold locking device 8, product calibration device 9, monitoring component 10 and monitoring terminal 11, the upper mold base 1 and the lower mold base 3 are connected by guide columns 2, and the punch 4 is fixed by the punch The base 5 is set on the upper mold base 1, the monitoring component 10 is set on the punch fixing base 5, the monitoring component 10 is electrically connected to the monitoring terminal, the punching table 6 is set on the lower mold base 3, and the forming mold 7 passes through the mold lock The tightening device 8 is fixed on the stamping workbench 6, and the product correction device 9 is arranged on the right side of the forming die 7; the forming die 7 is also provided with an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com