A leaf spring end processing unit

A processing unit and leaf spring technology, applied to wire processing, wire manufacturing of springs, household appliances, etc., can solve the problems of poor product forming stability, dependence on manual transfer and handling, and dependence on labor, so as to improve operation and connection efficiency, forming The effect of stable and reliable quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

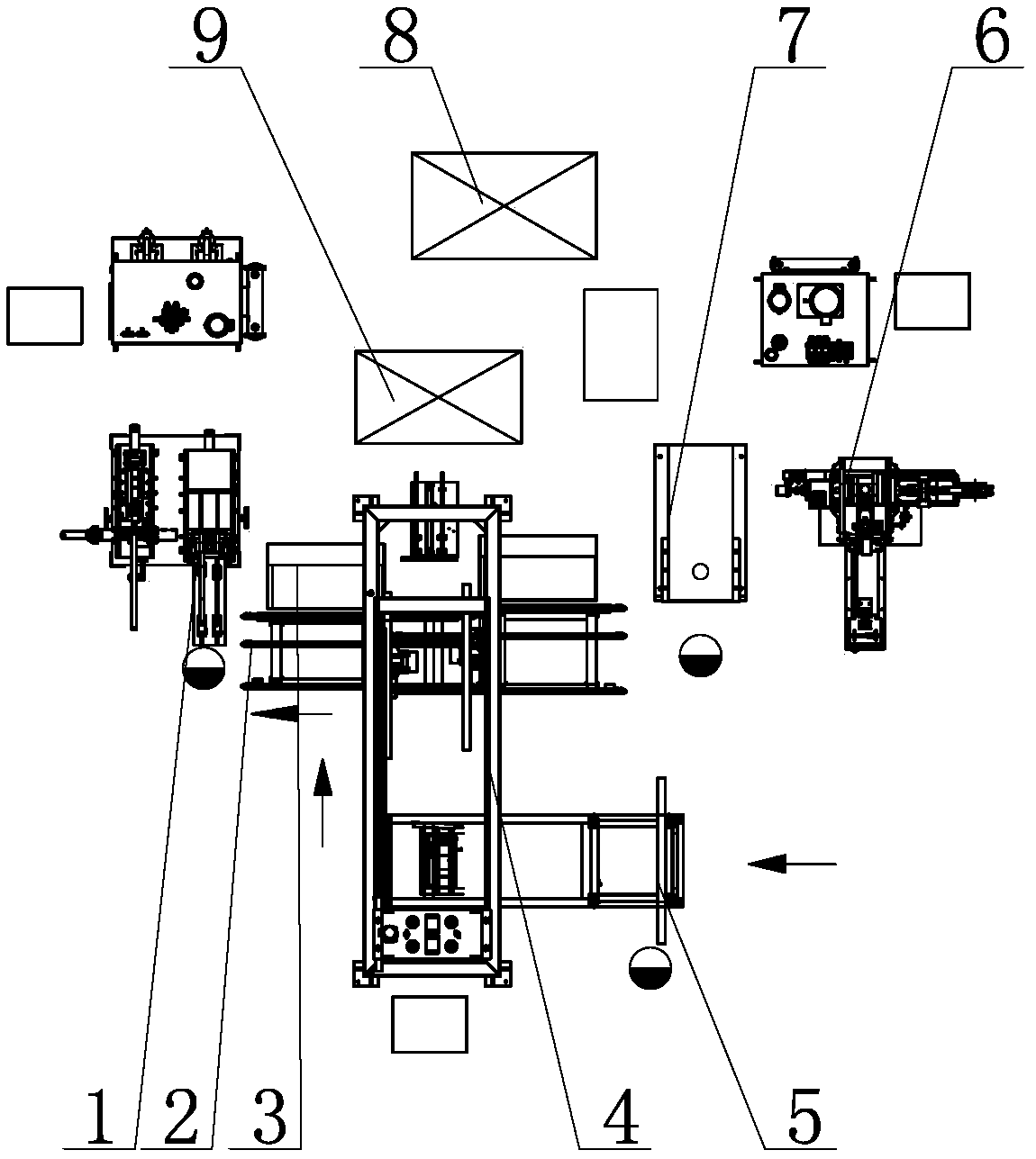

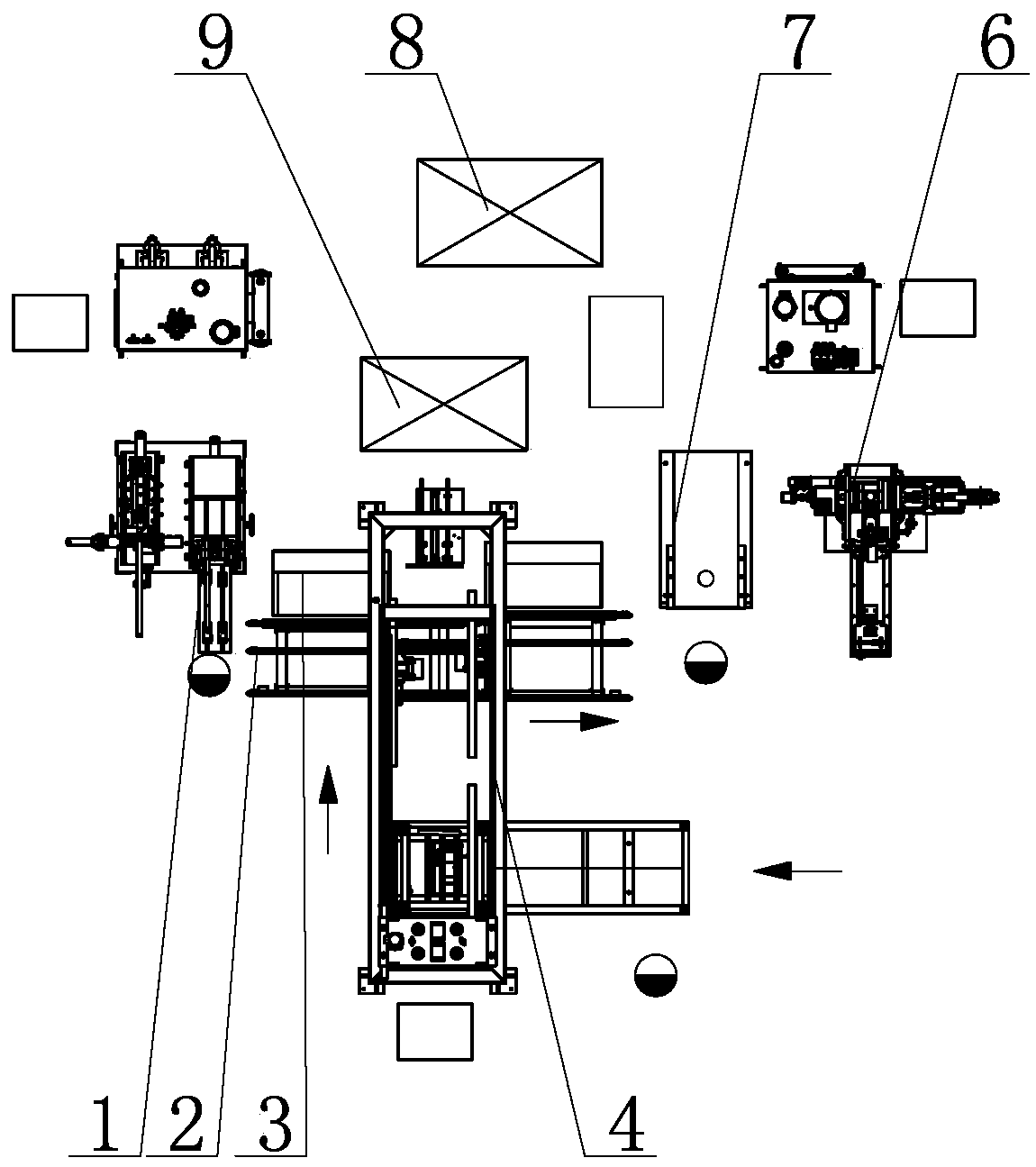

[0057] Such as figure 1 and 2 As shown, the leaf spring end processing unit according to the present invention includes a material frame, a feeding mechanism, a two-way conveying mechanism, an intermediate frequency induction heating furnace, an ear rubbing machine, a clip hole processing device, an open fixed table press and a package Earphones, the feeding mechanism includes an electromagnetic chuck and a feeding guide rail, the electromagnetic chuck can suck out the leaf spring from the material frame, and place it on the two-way conveying mechanism along the feeding guide rail; the intermediate frequency induction heating furnace can feed the leaf spring The end of the sheet is heated;

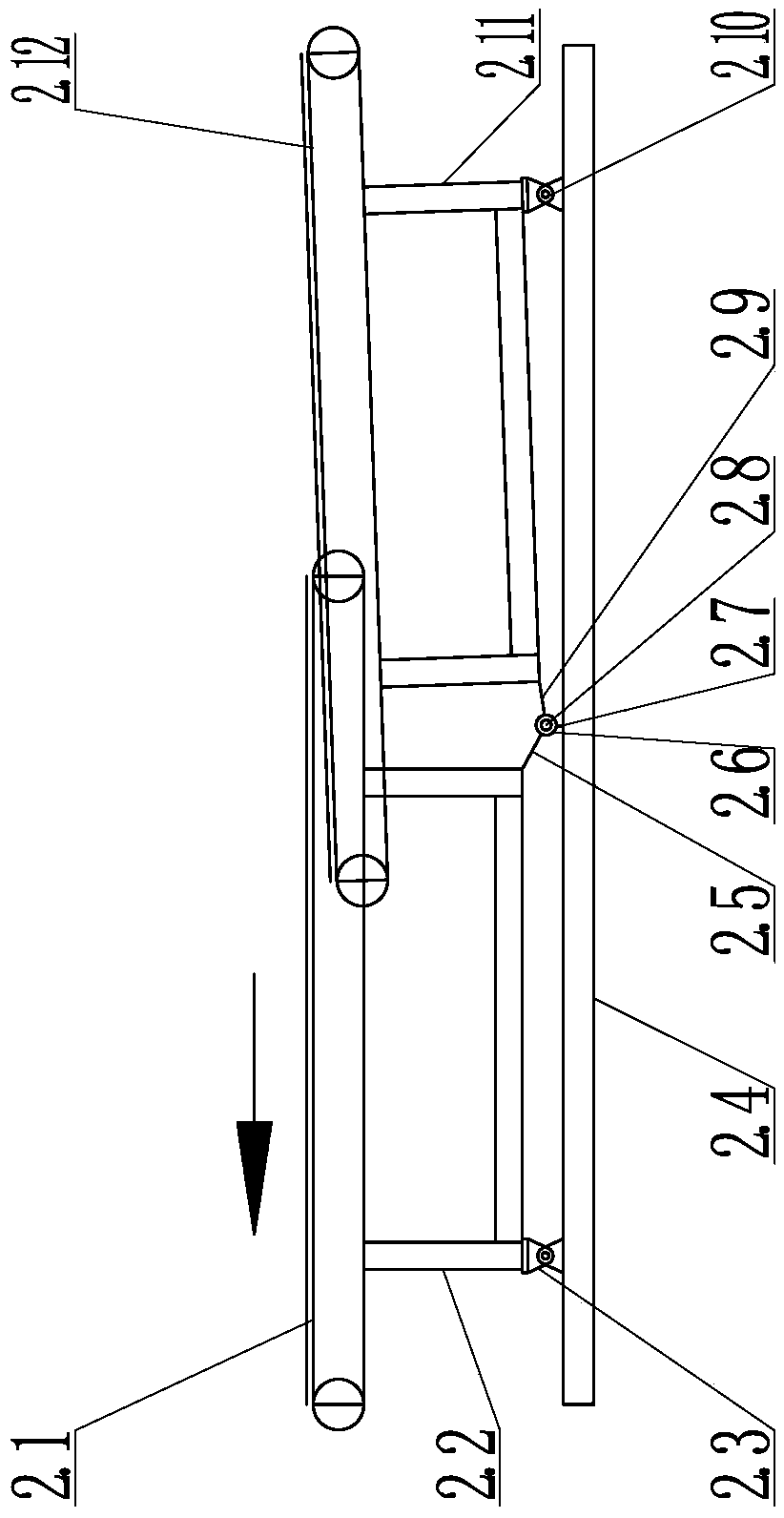

[0058] Such as image 3 and 4 As shown, the two-way conveying mechanism includes a base, a first conveying device and a second conveying device, the first conveying device is connected to the ear rubbing and shaping machine, and the second conveying device is connected to the earphone; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com