Low-noise assembling device for assembling automobile lamp holder seal ring

A technology for assembling devices and automobile lamp sockets, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low flatness of sealing rings, easy deviation in assembly work, high manual labor intensity, etc., and reduce manual operation. Fatigue, avoid surface unevenness, alarm prompt effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

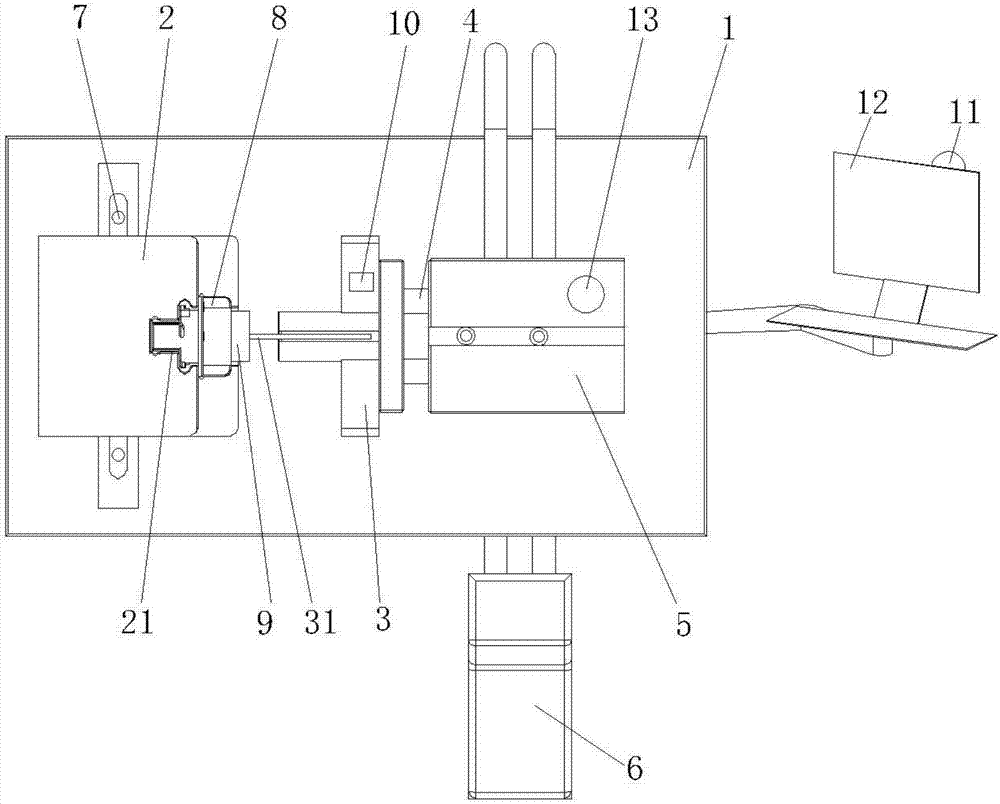

[0022] like figure 1 As shown, a low-noise assembly device for assembling sealing rings of automotive lamp holders in this embodiment includes a base 1, a lamp holder positioning fixture 2, a movable push seat 3, a telescopic rod 4, a cylinder 5, and a pedal Switch 6, bolt 7, force sensor 10, automatic alarm 11, controller 12 and detection mechanism 13.

[0023] The connection relationship of the above-mentioned components is as follows: the lamp holder positioning fixture 2 and the cylinder 5 are fixedly connected to the base 1 through bolts 7; In the card slot 21; the front end of the movable push seat 3 is inlaid with a push rod 31, the movable push seat 3 is driven by the cylinder 5 and linearly slid on the base 1 through two telescopic rods 4, the movable The front end of the push seat 3 corresponds to the position of the sealing ring 9; the cylinder 5 is connected to the foot switch 6; the cylinder 5 is connected to the external controller 12, and the top of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com