An idler roller adjustment device for a short material sander

An adjustment device, a technology of sanding machine, applied in the direction of grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of inability to adjust the spacing, inability to adjust the preload force, inability to transport short wood, etc. To achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

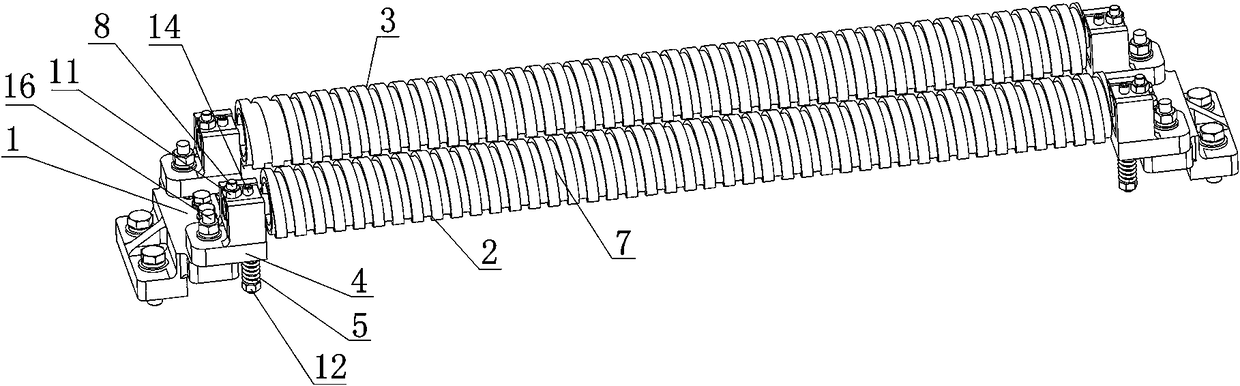

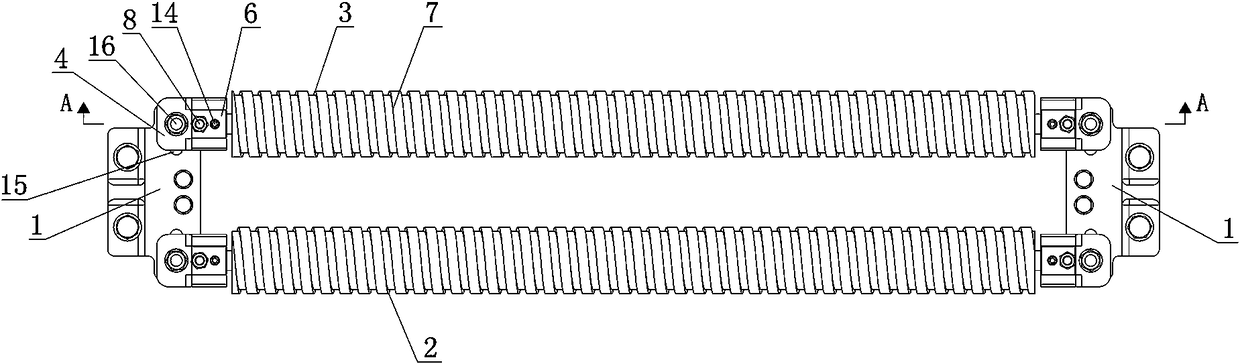

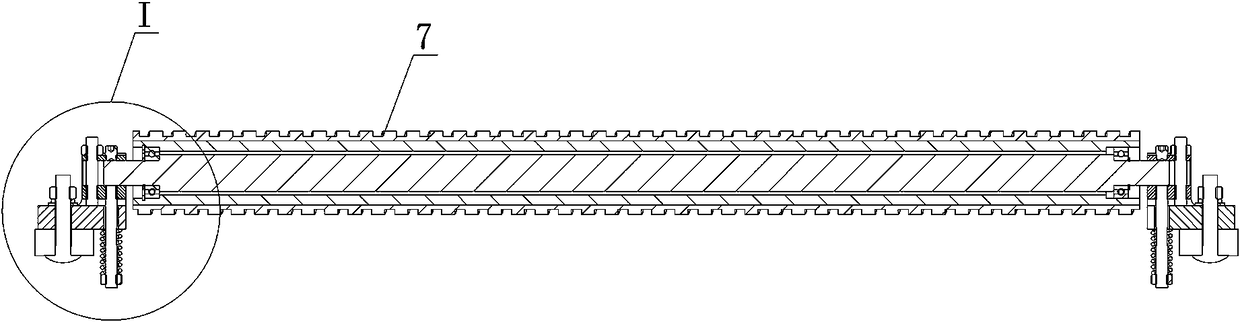

[0016] Such as Figure 1~4 As shown, an idler roller adjustment device for a short material sander, which includes two support base plates 1, and a pressing mechanism A2 and a pressing mechanism B3 are arranged between the two support base plates 1, and the pressing mechanism Mechanism A2 and pressing mechanism B3 are arranged symmetrically, and pressing mechanism comprises idler roller support 4, spring 5, roller bushing 6, idler roller 7, double-ended stud A8 and double-ended stud B9, and described idler The roller support 4 is fixed on the support bottom plate 1, the other end of the idler pressure roller support 4 extends outside the support bottom plate 1, and a groove is opened on the top of the extension part, and a pressure roller sleeve is arranged in the groove 6. There is a through hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com