A flexible feeder

A feeder and flexible technology, applied in the field of automated production, can solve the problem of feeding incompatible materials with differences, and achieve the effects of strong horsepower, accelerated feeding efficiency, and high transportation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

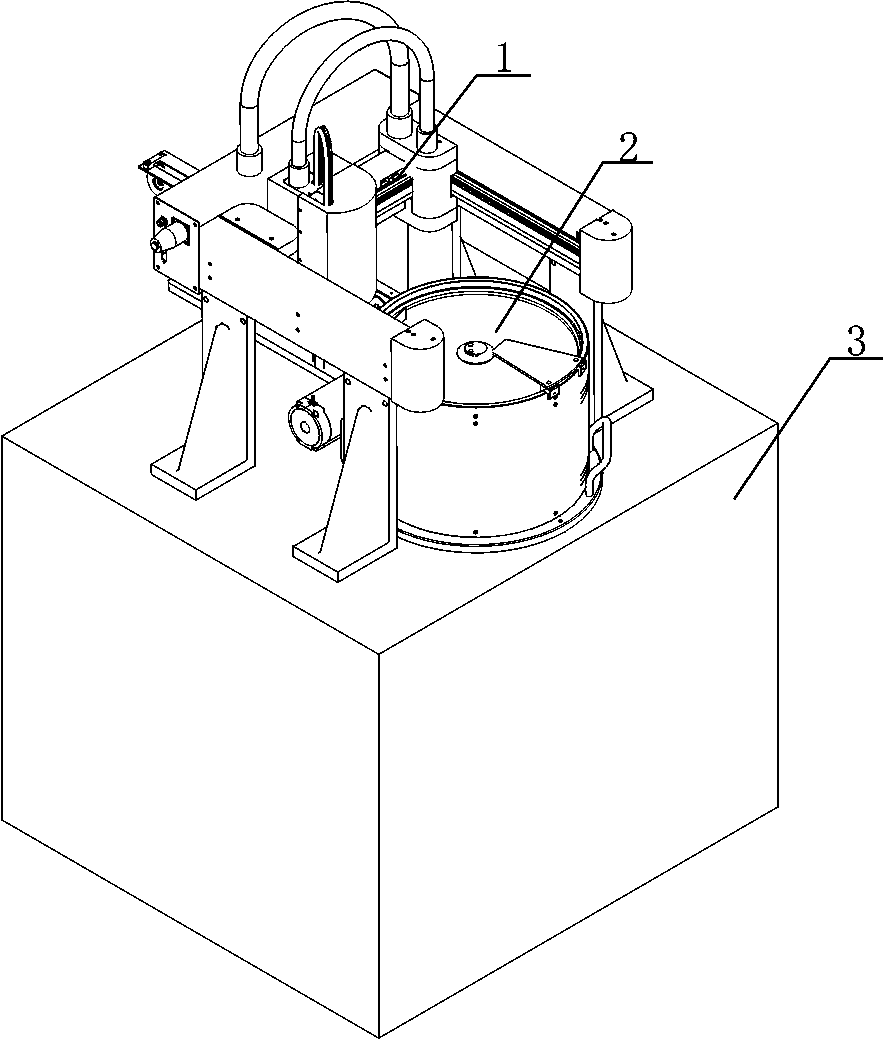

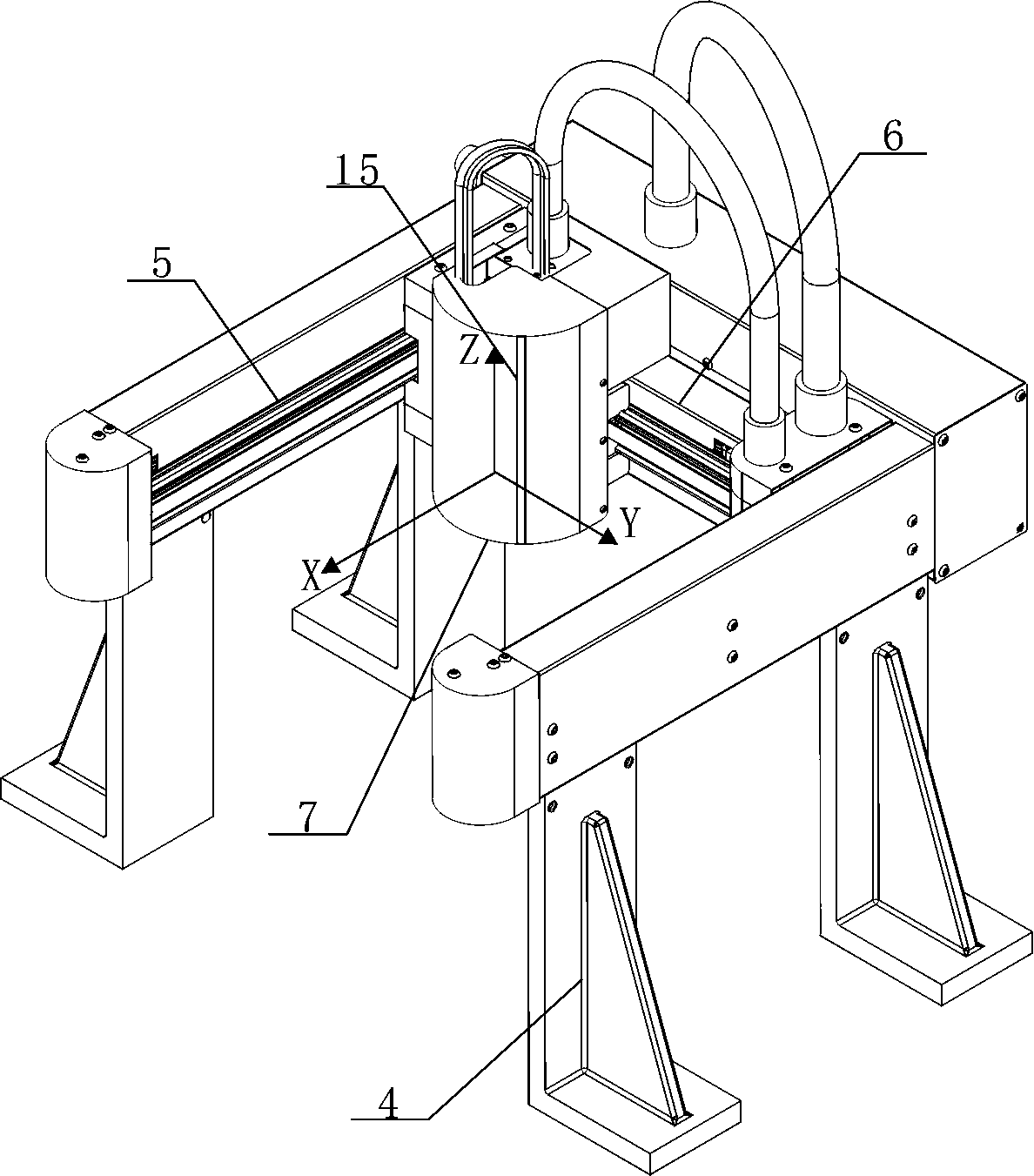

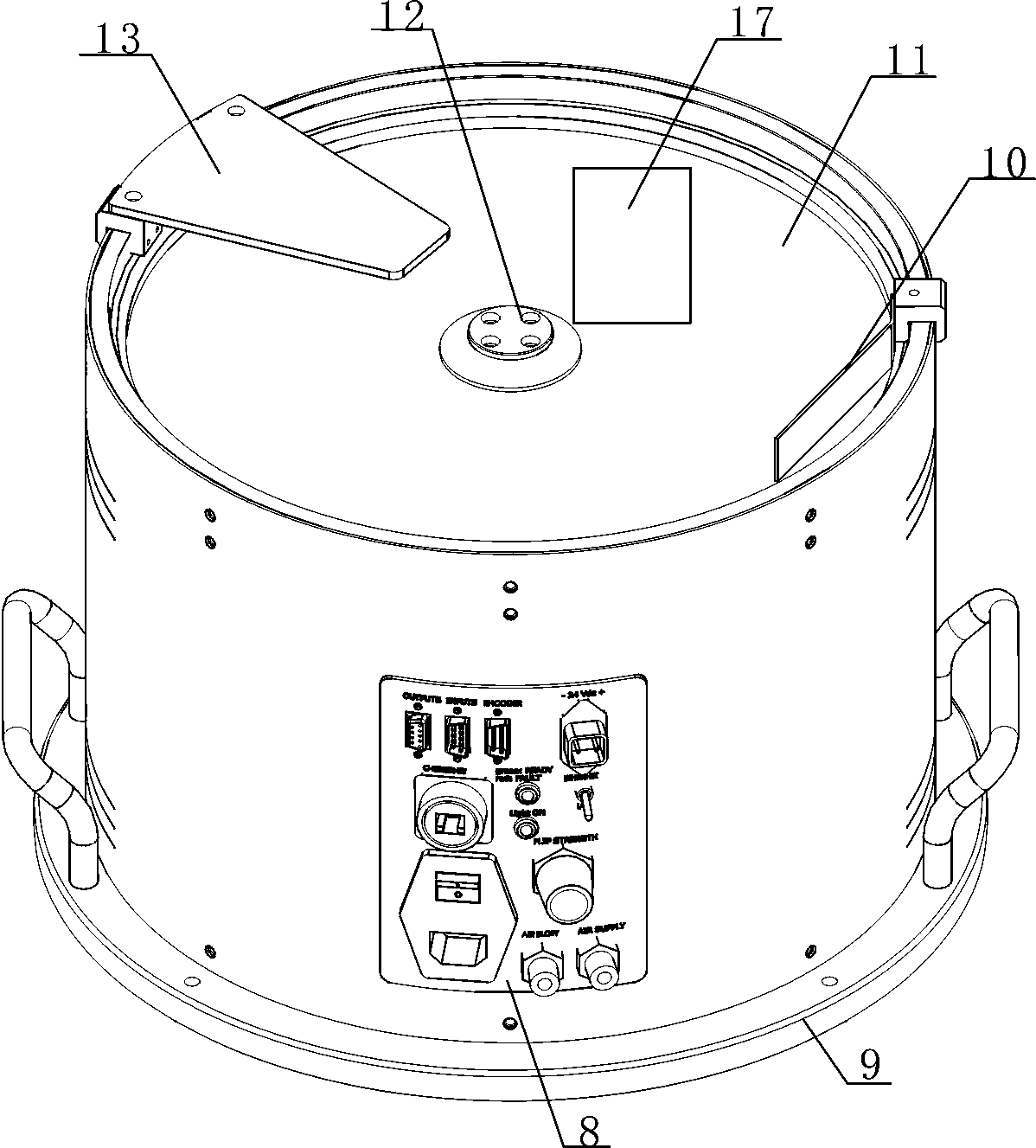

[0036] According to an embodiment of the present application, such as Figure 1-6 As shown, the flexible feeder of this solution includes a grabbing module 1, a storage bin 2 and a cabinet 3. The grabbing module 1 is fixed on the cabinet 3 , the storage bin 2 is installed in the space formed by the grabbing module 1 and the cabinet 3 , and the storage bin 2 and the grabbing module 1 are both accommodated in the protective c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com