Construction method of pipe gallery water-stopping belt

A construction method and waterstop technology, which are applied in the construction field of pipe gallery waterstops, can solve problems such as easily damaged buried waterstops, etc., and achieve convenient positioning, reduce the sagging range, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

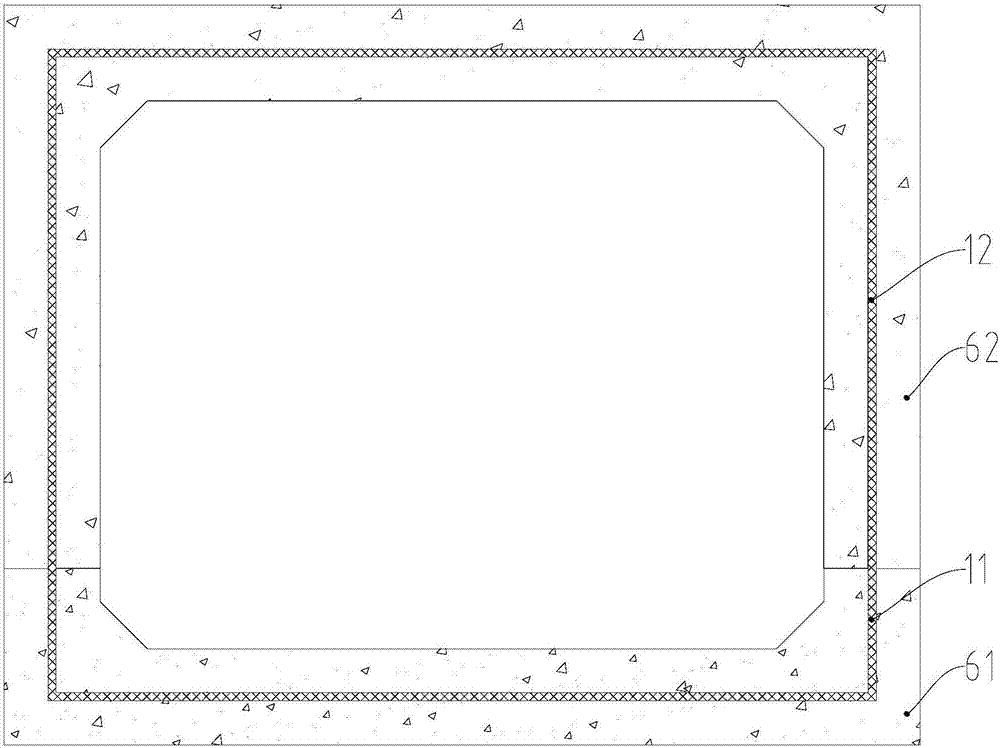

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

[0031] The construction method of the pipe gallery waterstop includes the following steps:

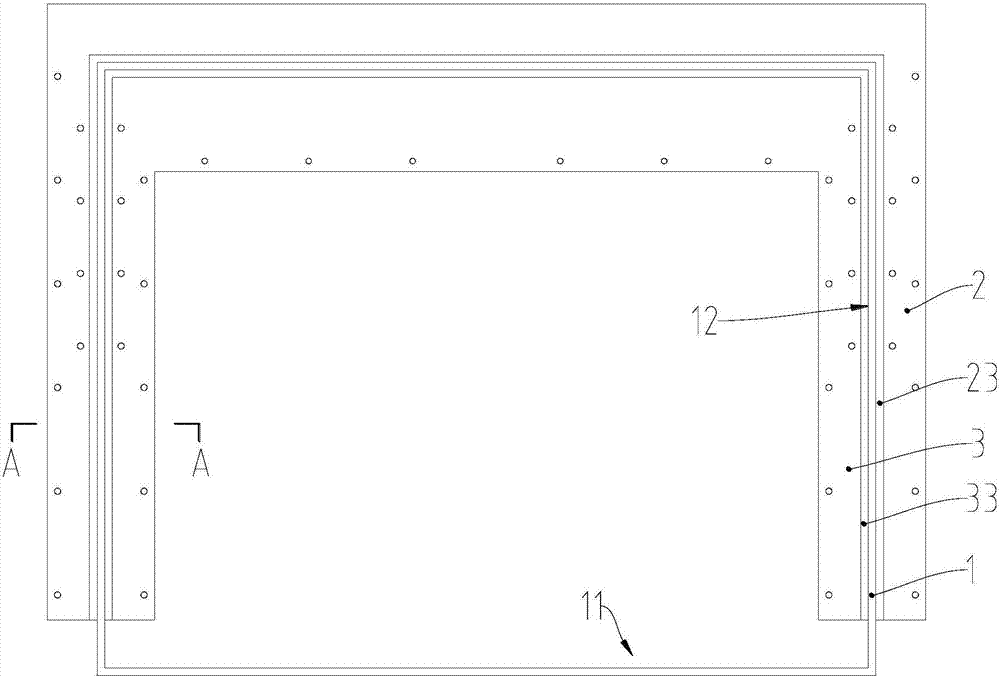

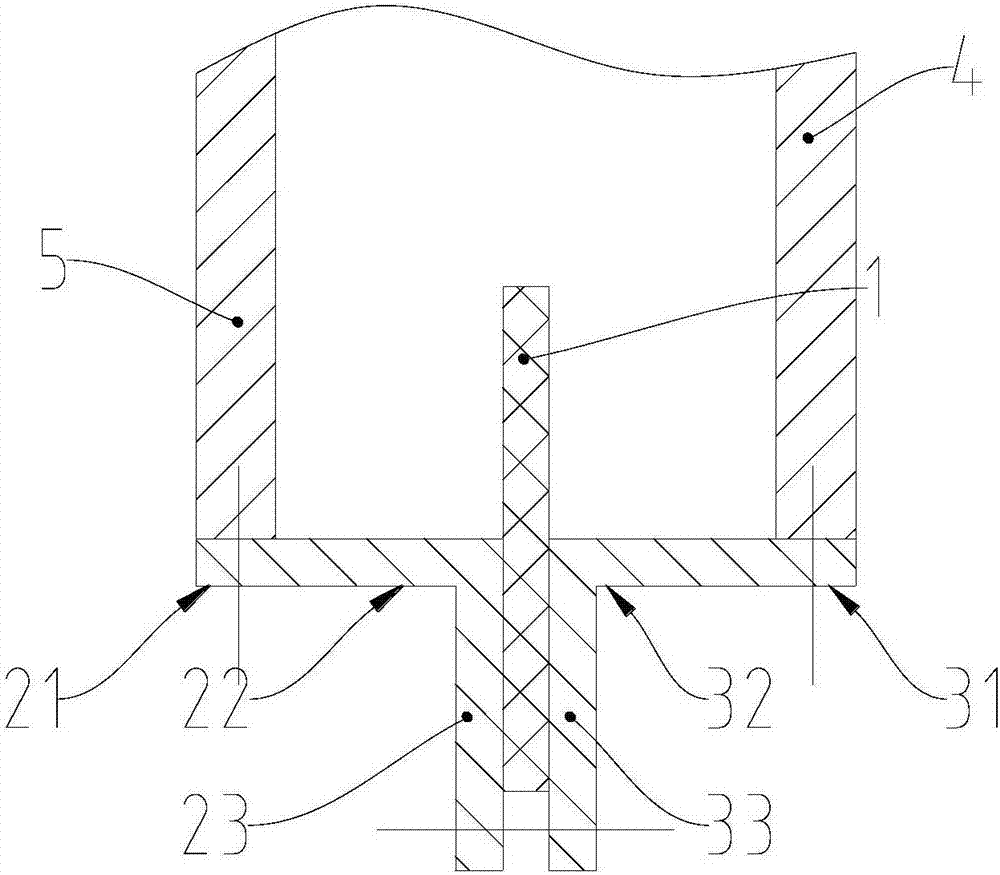

[0032] 1), make the waterstop positioning part, the waterstop positioning part includes the outer template 2 and the inner template 3; one section of the outer template 2 is the outer installation part 21, and the other section is the outer extension part 22; the inner template 3. One section is the inner installation part 31, and the other section is the inner extension part 32;

[0033] 2), the inner mold 4 and the outer mold 5 are supported in place;

[0034] 3), install the waterstop 1:

[0035] 3.1), install the inner formwork 3 on the inner end of the inner formwork 4 along the longitudinal direction of the pipe gallery, and connect the inner installation part 31 of the inner formwork 3 with the inner formwork 4 with bolts, and the inner extension part 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap